Auxiliary fitting device for robot to cross high-voltage iron tower

A robot and iron tower technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of inconvenient design, production and installation, large internal stress of the overall structure, poor adjustment and adaptability, etc., and achieves high practical value, simple structure and reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

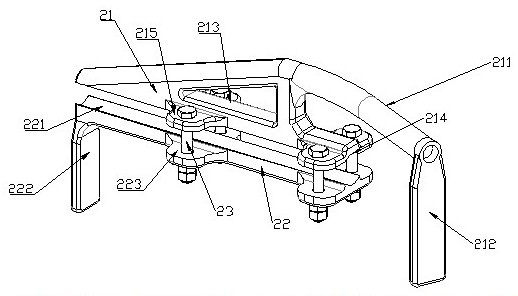

[0027] A variable clamp for an inspection robot to withstand tension crossing a bridge, including a track, an upper part 21 of a connecting wire clamp, a crimping mechanism, and a lower part 22 of a connecting wire clamp, and the upper part 21 of the connecting wire clamp or the lower part 22 of the connecting wire clamp is fixed and useful On the track where the inspection robot walks up and down the ground wire, the crimping mechanism is fixedly arranged on the upper part 21 of the connecting wire clamp or the lower part 22 of the connecting wire clamp, and the ground wire of the high-voltage line is fastened between the upper part 21 of the wire clamp and the lower part 22 of the connecting wire clamp.

[0028] Further, in this embodiment, the crimping mechanism is a crimping tube 211, which is a round tube, and the track is a cylindrical structure with a semicircular cross section. The track is extended and fixedly connected to the crimping tube 211, and the track is located...

Embodiment 2

[0048] The difference from Embodiment 1 is that the crimping mechanism in this embodiment includes fasteners, a first arc-shaped tube and a second arc-shaped tube. When working, the first arc-shaped tube and the second arc-shaped tube are combined to form a round tube. The first arc tube and the second arc tube are fixedly connected by a fastener, and the right end of the track is fixedly connected to the left end of the first arc tube and the left end of the second arc tube.

[0049] Further, the fastener in this embodiment includes two semi-circular hoops and screws, the two semi-circular hoops are sleeved on the first arc-shaped tube and the second arc-shaped tube, and the two semi-circular hoops are fixedly connected by screws.

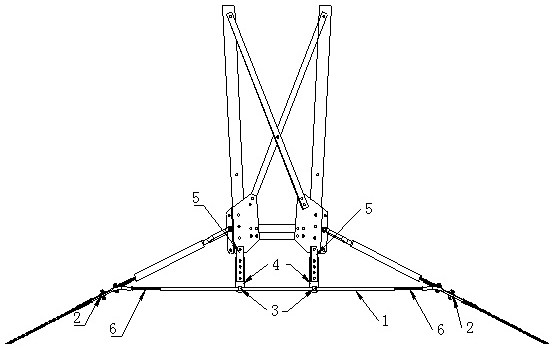

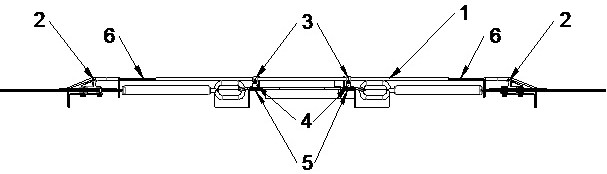

[0050] Further, an auxiliary fitting device in this embodiment includes four connecting wire clamps, two rail steel pipes 1 for the robot to walk over the tower, two steel strands 6, and four supports for supporting the rail steel pipe 1 Line clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com