Power transmission line tensioning type inspection robot energy-saving suspension device

A technology for inspection robots and power transmission lines, which is applied to overhead lines/cable equipment, etc., can solve the problems of reducing inspection accuracy and poor safety, and achieve the effect of reducing centrifugal force requirements, improving safety level, and reducing swing amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

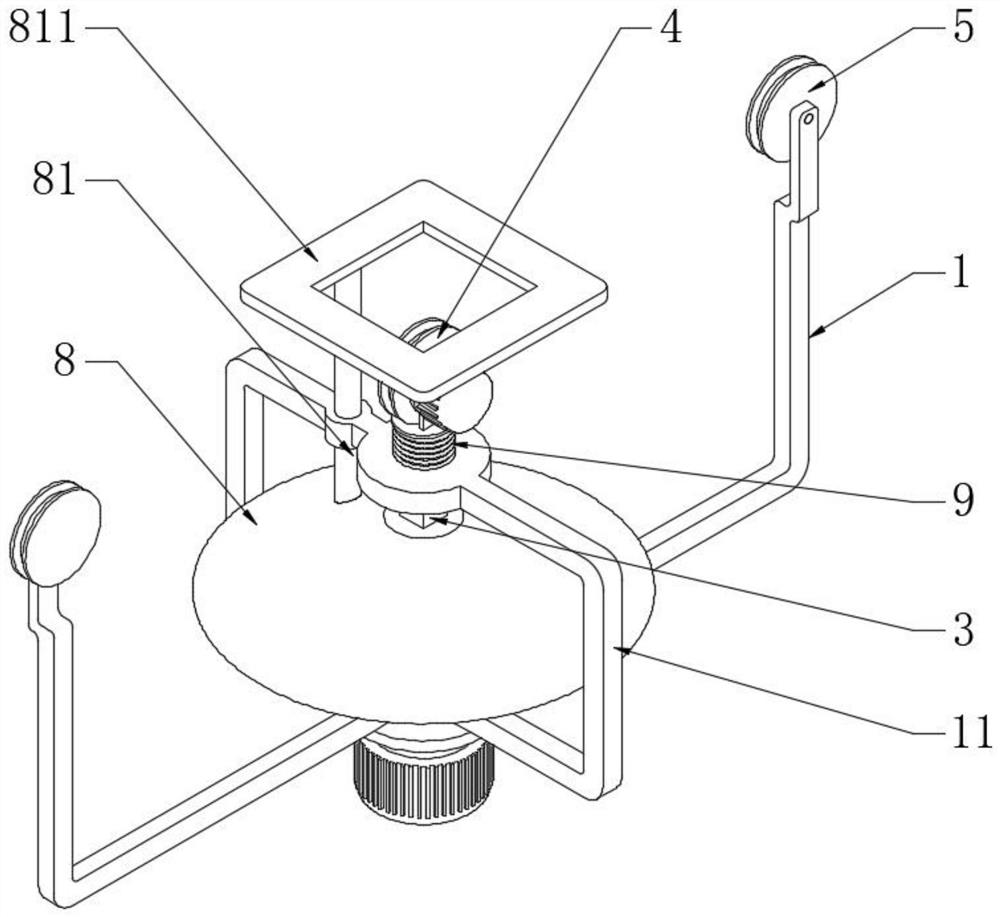

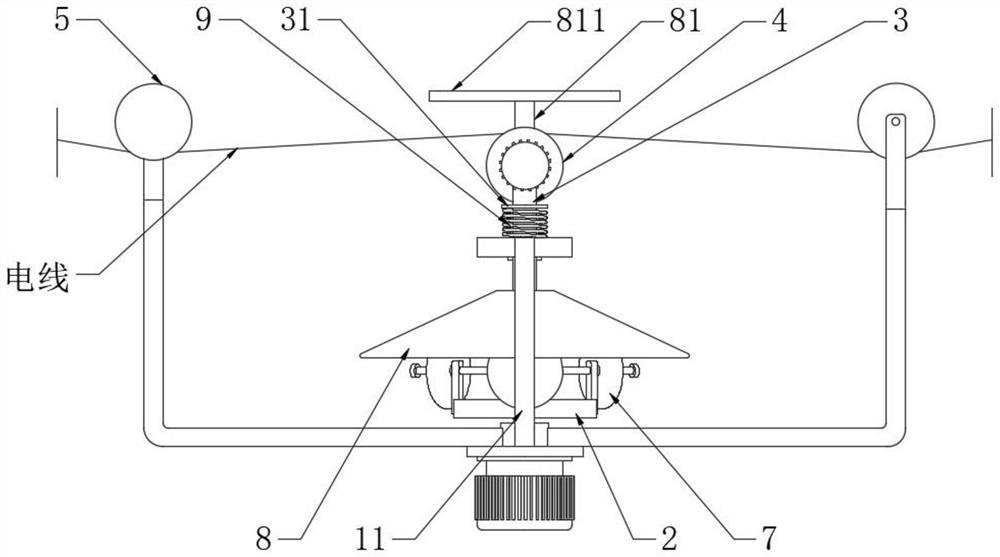

[0030] see Figure 1-3 , an energy-saving suspension device for a transmission line tension type inspection robot, comprising a suspension frame 1, a turntable 2 is arranged in the middle of the suspension frame 1, the rotation axis of the turntable 2 is vertically distributed, the suspension frame 1 is a groove structure and its A support frame 11 is provided on the top, and the support frame 11 is elastically slid up and down to be connected with vertically distributed support columns 3. Preferably, the support frame 11 is provided with a guide hole 111 that is slidably matched with the support column 3, and the outer wall of the support column 3 And near the top, a baffle plate 31 is fixedly arranged, and the support column 3 is sleeved with a return spring 9 between the baffle plate 31 and the support frame 11; the support column 3 is located on the top of the turntable 2, and the top of the support column 3 is provided with In the middle sheave 4, the suspension frame 1 i...

Embodiment 2

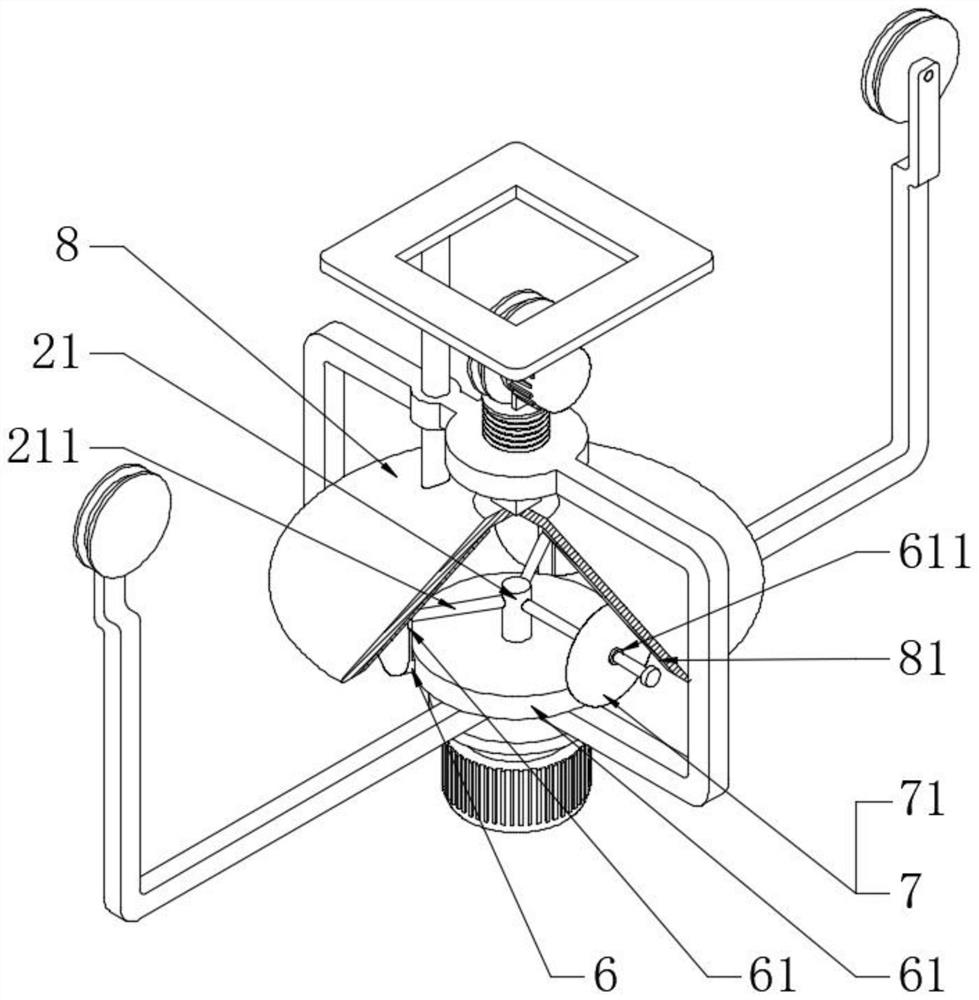

[0032] see Figure 4 with Figure 5 The difference from Embodiment 1 is that one end of the support sleeve 611 is swingably connected to the vertical plate 61, the swing axis of the support sleeve 611 is vertically distributed and the swing angle range is 15-25 degrees, and a hinge can be set on one side of the vertical plate 61 One end of the hinge seat and the support sleeve 611 is rotationally connected, and the hinge base is provided with limit plates located on both sides of the support sleeve 611. The two limit plates are used to limit the swing range of the support sleeve 611. During the high-speed rotation of the turntable 2 Among them, the axis of rotation of the roller 7 is deflected relative to the radial direction of the turntable 2. At this time, the roller 7 has a tendency to move outward when rolling along the inner wall of the conical cover 8, that is to say, it has a tendency to climb outward. Thus, the rolling plate 7 can push the support column 3 to rise, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com