Circulating type container horizontal transportation system and method

A technology of horizontal transportation and transportation method, applied in transportation and packaging, storage devices, loading/unloading, etc., can solve the problems of inconsistent running direction of trolleys, low container transportation efficiency, low transportation efficiency, etc., to improve the horizontal transportation efficiency and labor force. Low cost and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

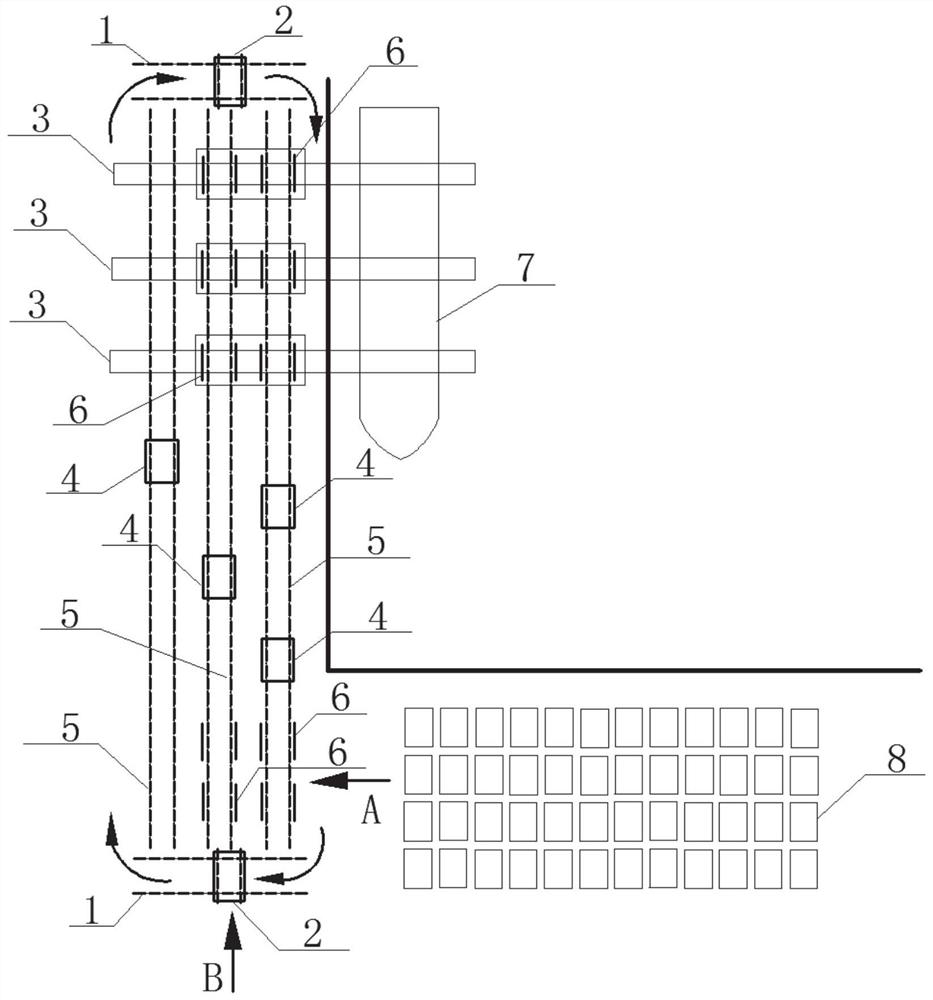

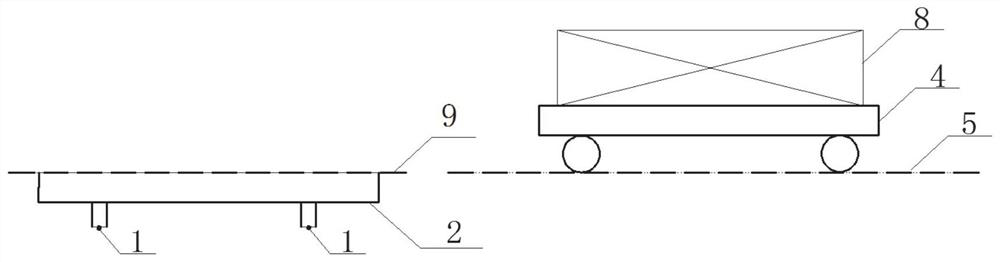

[0034] See how Figure 1-3 , the invention discloses a circular container horizontal transport system, comprising a plurality of horizontal transport vehicles and traversing trolleys for transporting containers; the horizontal transport vehicles are placed on the first transport track; the traversing trolleys are placed on the traversing track The traversing track and the first transport track are both located on the ground; the traversing track and the first transport track are two parallel tracks with a preset gauge distance.

[0035] The quay crane is located on the ground, and the quay crane is located above the first transportation track. The quay crane is used to transport the container on the ship to the shelving frame below it; A transportation track is separated by a preset distance; the traversing track is distributed at both ends of the first transportation track; and there are at least two parallel distributions of the first transportation track.

[0036] The shel...

Embodiment 2

[0041] This embodiment relates to a circular container horizontal transport method, based on the circular container horizontal transport system in Embodiment 1. Specific steps are as follows:

[0042] Step 1: The container is placed on the shelf at one end of the quay crane;

[0043] Step 2: Transport the container on the shelf at one end of the quay crane to the horizontal transport vehicle;

[0044] Step 3: The horizontal transport vehicle is transported to the yard end along the shore bridge end of the first transport track, and the container on the horizontal transport vehicle is transported to the shelving rack at the yard end;

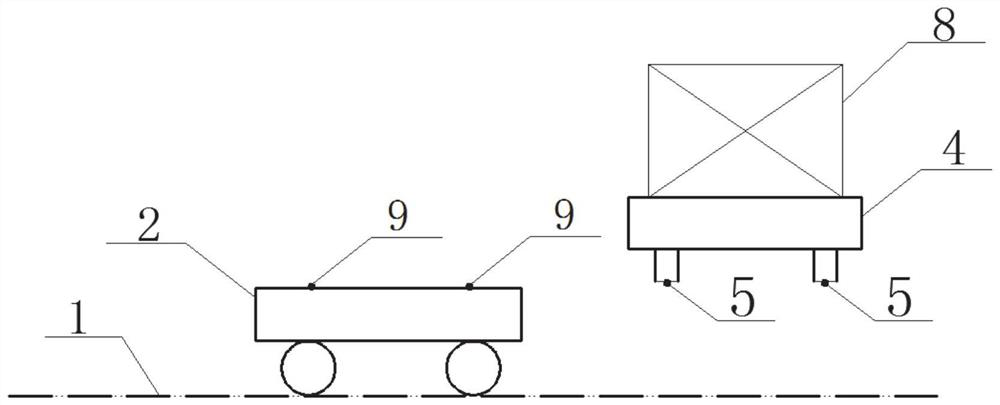

[0045] Step 4: The traversing trolley at one end of the first transport track moves on the traversing track. When the second transport track of the traversing trolley docks with the first transport track, the horizontal transport trolley moves to the top of the traversing trolley through the second transport track ;

[0046] Step 5: The traver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com