Arch dam mass concrete crack control method

A large-volume concrete and control method technology, applied in arch dams, dams, buildings, etc., can solve problems such as cracks in large-volume concrete of dams, achieve the effects of accelerating flow speed, improving heat transfer efficiency, and delaying heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

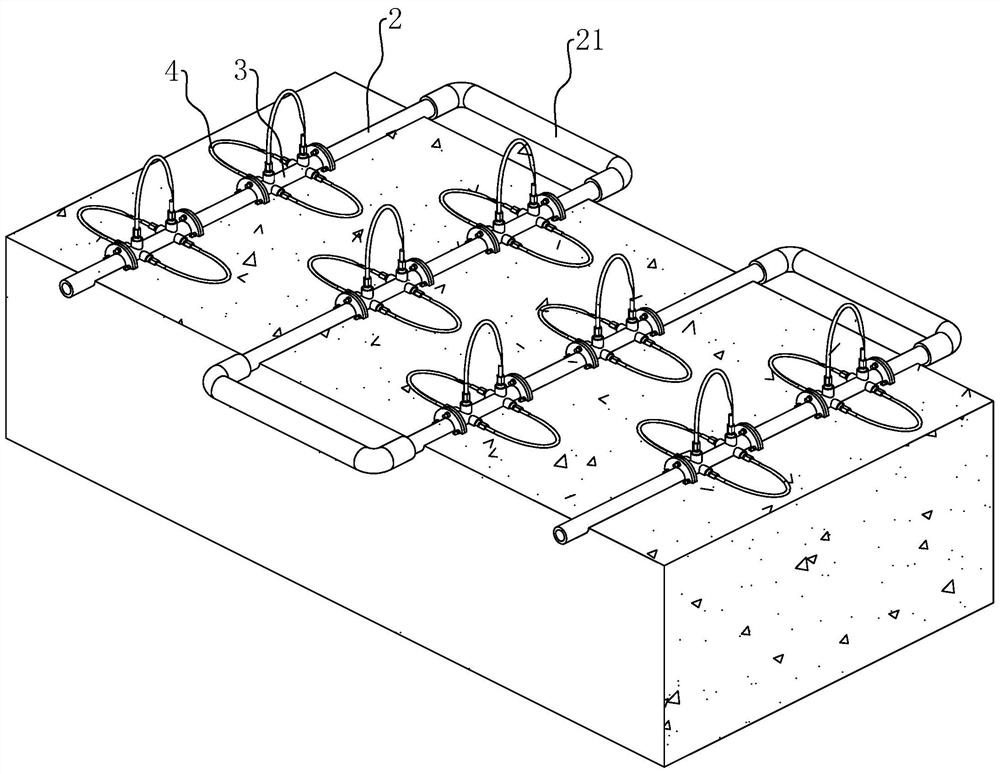

[0064] refer to Figure 7 , the difference between this embodiment and Embodiment 1 is that the secondary pipe 2 in this embodiment includes two secondary pipe joints, the retaining edge 40 is arranged at one end of the secondary pipe joint, and the two secondary pipe joints are far away from the retaining edge 40 A rubber hose 42 is connected between one end of the two.

[0065] The implementation principle of Embodiment 2 is as follows: first install the two auxiliary pipe joints on the corresponding connectors 33, and then use the rubber hose 42 to connect the two auxiliary pipe joints; the auxiliary pipe joints of different lengths can be selected to change the concrete interior. The heat dissipation area is large enough to meet the heat dissipation requirements of different volumes of concrete. The shape and length of the auxiliary pipe 4 are easy to adjust. The rubber hose 42 is easy to obtain materials and has good bending performance.

Embodiment 3

[0067] refer to Figure 8 The difference between this embodiment and Embodiment 2 is that, in this embodiment, a metal bellows 43 is connected between the ends of the two auxiliary pipe joints away from the retaining edge 40 .

[0068] The implementation principle of Embodiment 3 is as follows: first install two auxiliary pipe joints on the corresponding connectors 33, and then use metal bellows 43 to connect the two auxiliary pipe joints; the auxiliary pipe joints of different lengths can be selected, thereby changing the concrete interior. The heat dissipation area is large enough to meet the heat dissipation requirements of different volumes of concrete. The shape and length of the auxiliary pipe 4 are easy to adjust. The metal bellows 43 is easy to obtain materials and has good bending performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com