Construction method of cold box foundation lined with box body thin metal plates

A construction method and metal plate technology, applied in infrastructure engineering, construction, etc., can solve the problems of large impact on construction progress, high cost of input measures, and complicated construction, so as to shorten the construction period, reduce construction costs, and reduce construction costs. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

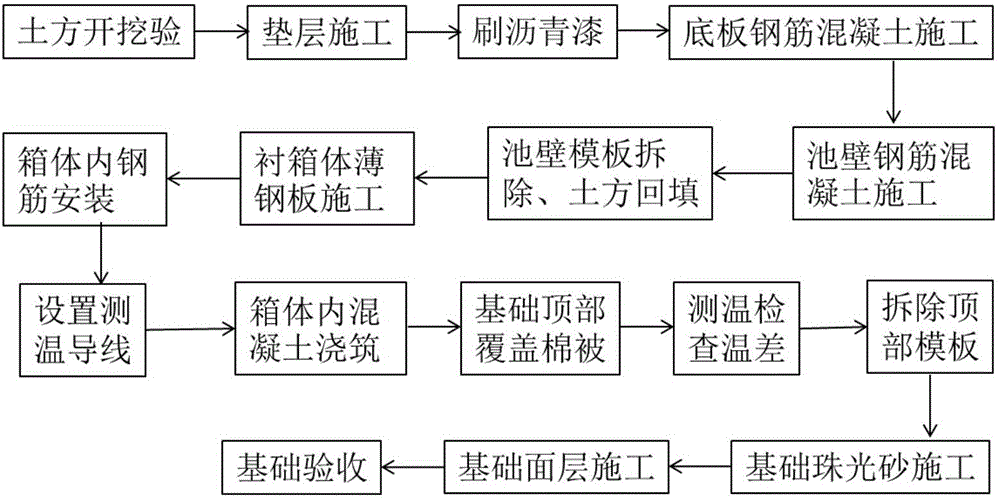

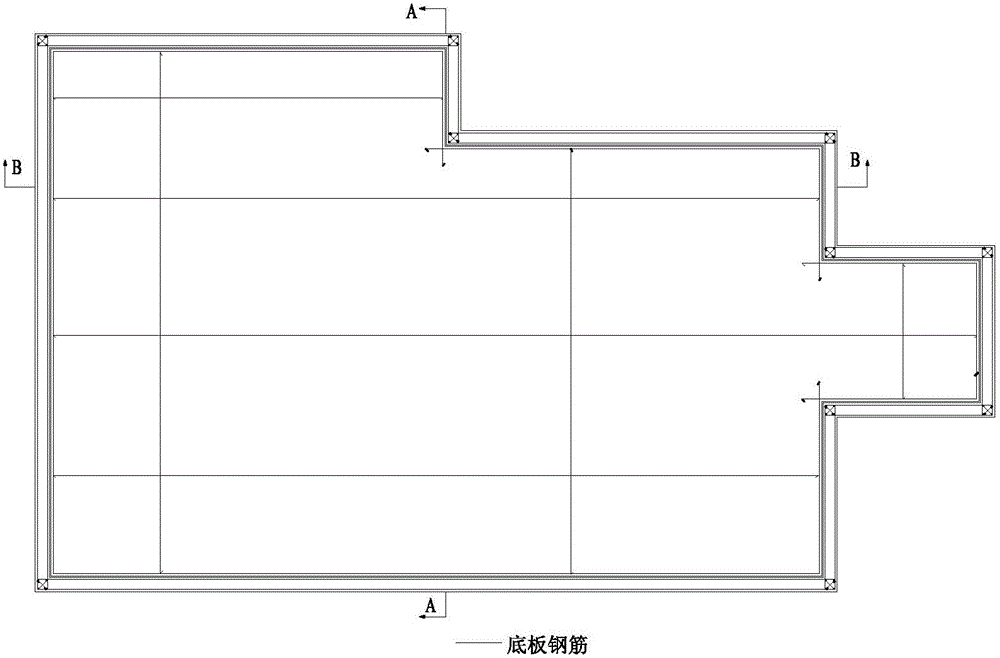

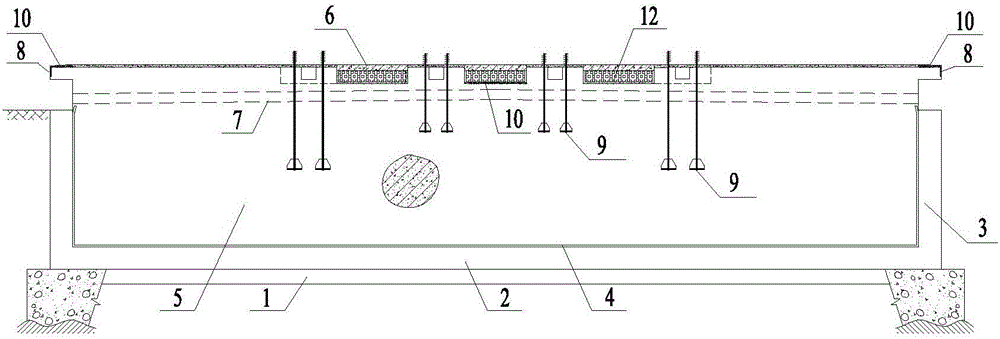

[0036] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the construction method of the cold box foundation of a thin metal plate lined box body in this embodiment, taking the winter construction of the cold box foundation of Xing'an League Chengtai 63000Nm3 / h air separation plant project as an example, includes the following steps:

[0037] (a) Earthwork and cushion construction

[0038] Excavators are used for earthwork excavation and foundation pit inspection. According to the design drawings, C15 rubble concrete is used for the construction of the concrete cushion layer 1, and the top surface of the concrete cushion layer 1 is brushed with asphalt cold primer oil;

[0039] (b) Construction of reinforced concrete bottom slab 2 and reinforced concrete wall slab 3

[0040] Using C40 concrete, first construct the anti-seepage and frost-resistant reinforced concrete floor 2 between the thin metal plate 4 of the lining box and the concrete cushion 1; then insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com