Half-reverse construction method for split-level steel structure building

A construction method and technology of steel structure, applied in the direction of building, building structure, processing of building materials, etc., can solve the problem of prolonging the occupation time of the lower area, and achieve the effect of facilitating installation, avoiding potential safety hazards and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

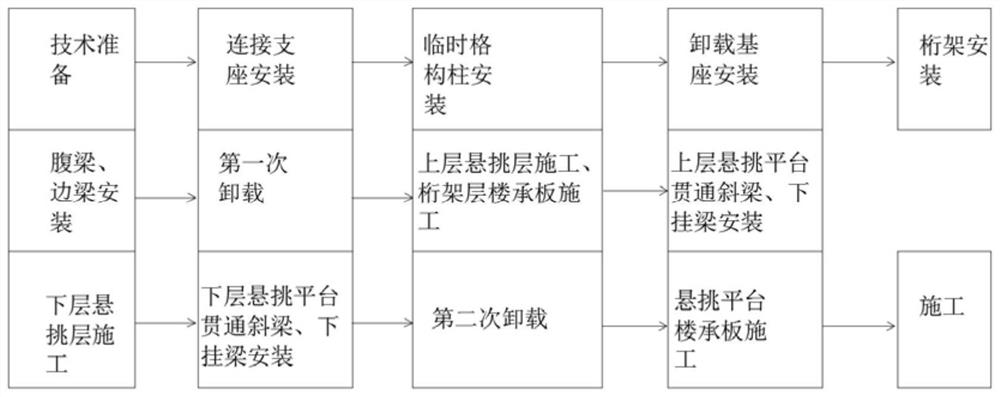

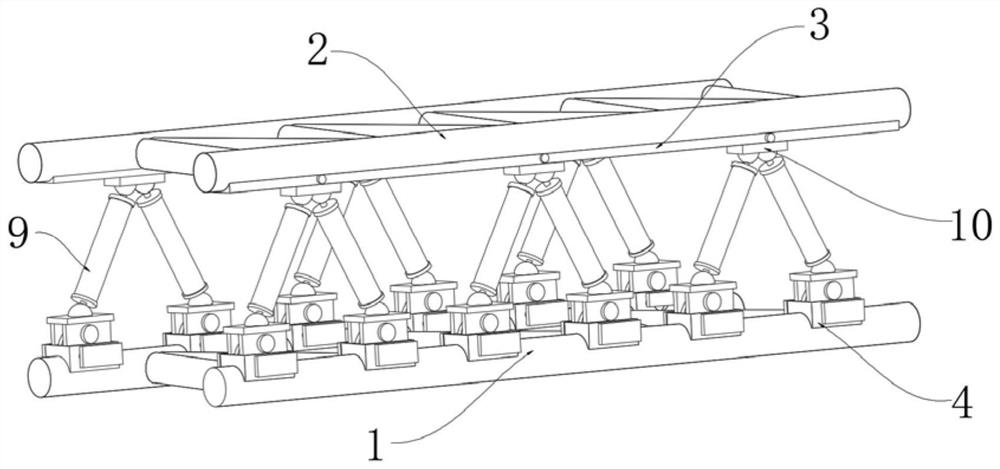

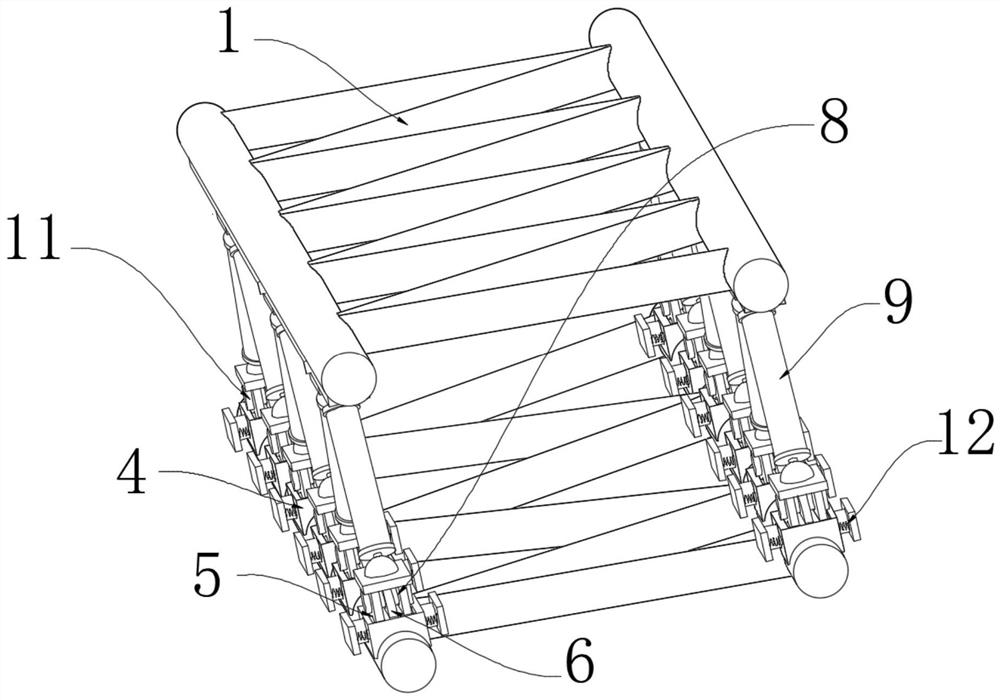

[0078] refer to Figure 1-5 , a half-upside-down construction method for a split-story steel structure building, comprising the steps of:

[0079] 1. Technical preparation

[0080] (1) Deepen the construction drawings from top to bottom, calculate the construction load and simulate unloading stress distribution changes, and the deepened drawings have been reviewed and approved by the design institute, and have passed the review of the drawing review agency.

[0081] (2) Compile the upward-downward and reverse-up construction plan, which shall be reviewed and approved by the design unit, supervision unit, and construction unit, and passed through expert demonstration.

[0082] (3) Calculate the installation height of the lattice column and process it in advance.

[0083] 2. Installation of traffic body support

[0084] Embedded parts installation. The steel column horse stool is buried in the raft foundation, the height of the horse stool = the thickness of the raft - the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com