Step temperature autoclave curing method for fly ash unburned bricks

A step temperature and autoclave curing technology, which is used in the step temperature autoclave curing, processing other waste residue-free bricks and aerated concrete fields, can solve the problem of non-burning bricks that are cooked outside and endogenous, high autoclave curing temperature, and autoclaved curing. Long time and other problems, to achieve the effect of uniform internal and external temperature, improve internal compactness, and shorten high temperature autoclave curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

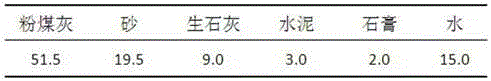

Method used

Image

Examples

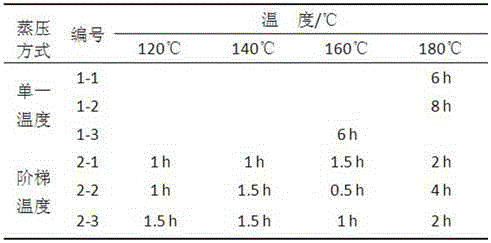

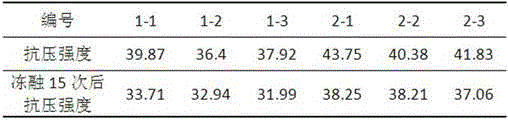

Embodiment 1

[0029] A step-temperature autoclave curing method for fly ash unburned bricks, specifically: placing fly ash unburned bricks made by the existing process in an autoclave and curing with saturated steam, and dividing into four stages according to the temperature. : The holding temperature of the first stage is 120℃, the gauge pressure of the autoclave is 0.20MPa, and the holding time is 1h; the holding temperature of the second stage is 140℃, the gauge pressure of the autoclave is 0.36MPa, and the holding time is 1h; The holding temperature of the third stage is 160°C, the gauge pressure of the autoclave is 0.62MPa, and the holding time is 1.5h; the holding temperature of the fourth stage is 180°C, the gauge pressure of the autoclave is 1MPa, and the holding time is 2h.

Embodiment 2

[0031] A step-temperature autoclave curing method for fly ash unburned bricks, specifically: placing fly ash unburned bricks made by the existing process in an autoclave and curing with saturated steam, and dividing into four stages according to the temperature. : The holding temperature of the first stage is 115℃, the gauge pressure of the autoclave is 0.17MPa, and the holding time is 0.5h; the holding temperature of the second stage is 130℃, the gauge pressure of the autoclave is 0.27MPa, and the holding time is 2h; The holding temperature of the third stage was 158°C, the gauge pressure of the autoclave was 0.59MPa, and the holding time was 0.5h; the holding temperature of the fourth stage was 200°C, the gauge pressure of the autoclave was 1.56MPa, and the holding time was 4h.

Embodiment 3

[0033] A step-temperature autoclave curing method for fly ash unburned bricks, specifically: placing fly ash unburned bricks made by the existing process in an autoclave and curing with saturated steam, and dividing into four stages according to the temperature. : The holding temperature of the first stage is 110℃, the gauge pressure of the autoclave is 0.14MPa, and the holding time is 1.5h; the holding temperature of the second stage is 138℃, the gauge pressure of the autoclave is 0.34MPa, and the holding time is 1h; The holding temperature of the third stage was 155°C, the gauge pressure of the autoclave was 0.54MPa, and the holding time was 1.5h; the holding temperature of the fourth stage was 190°C, the gauge pressure of the autoclave was 1.26MPa, and the holding time was 6h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com