Anti-pressure-relief energy-saving gas compressor

A gas compressor and energy-saving technology, applied in the field of air pressure components, can solve the problem of serious energy consumption of gas compressors, and achieve the effects of improving the fixing effect, expanding the cross-sectional area, and improving the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

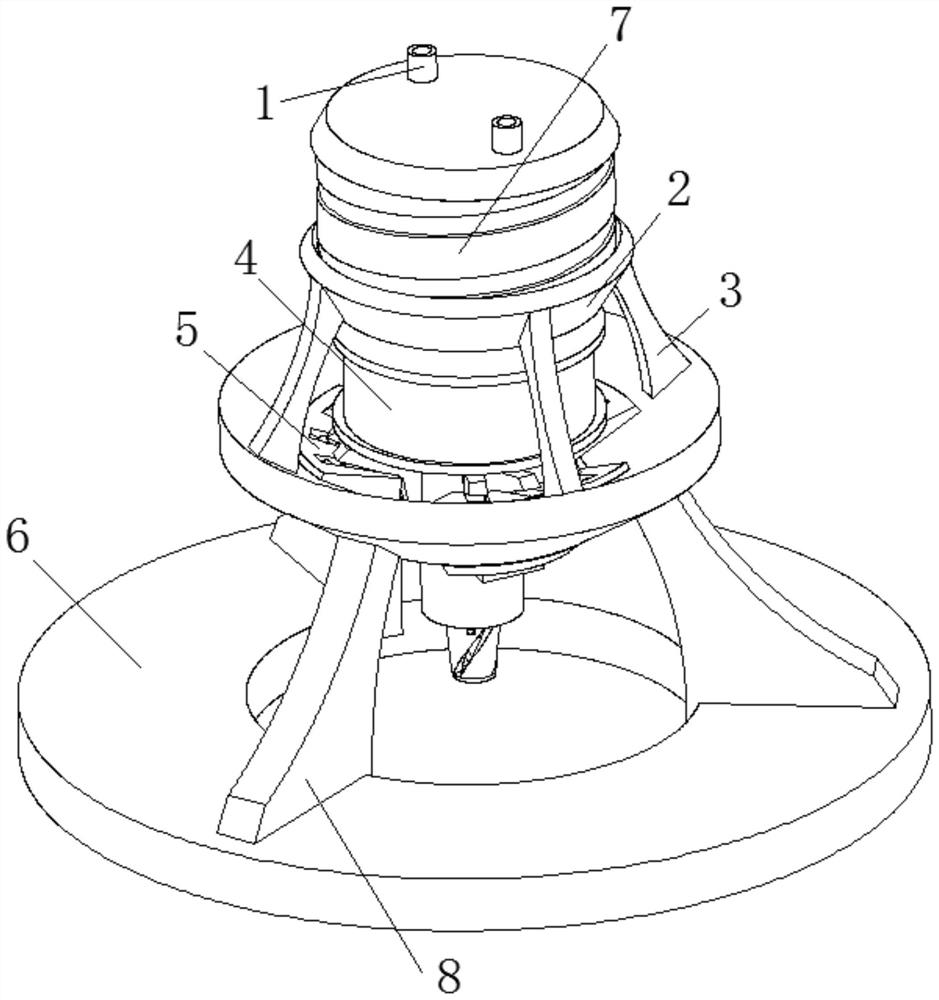

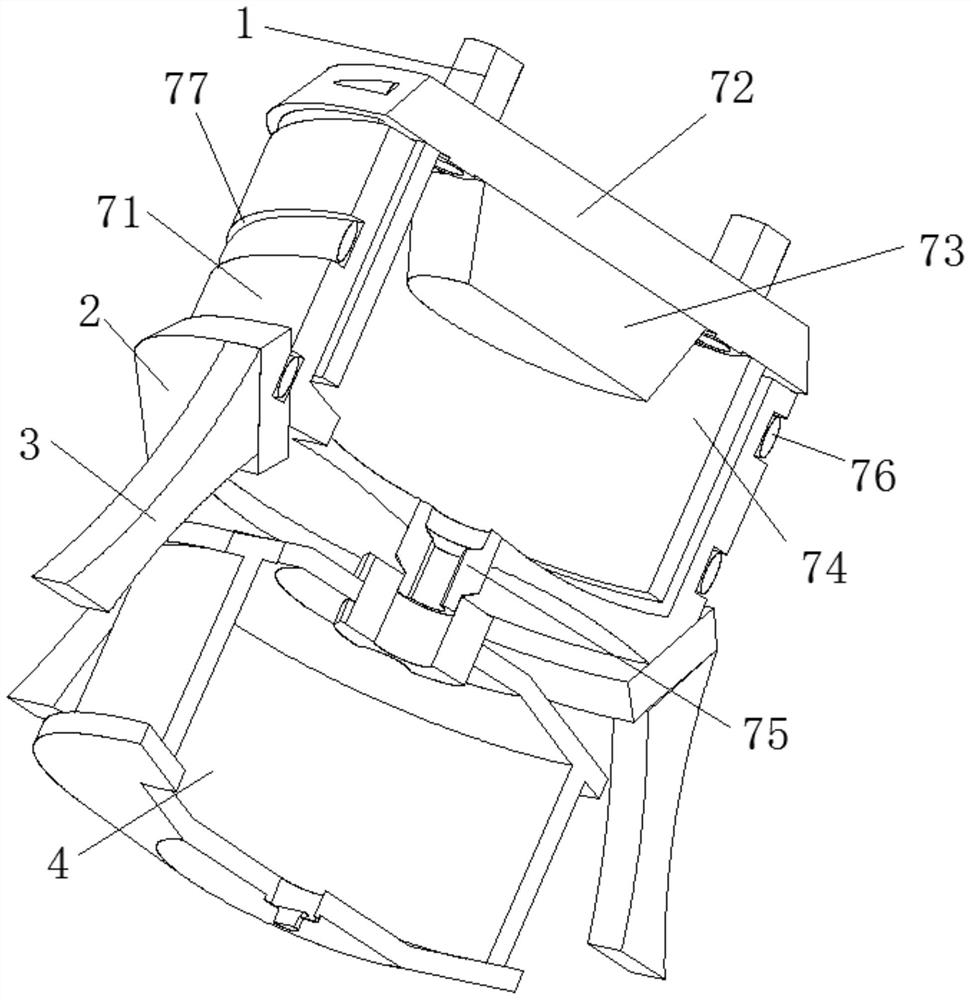

[0035] like Figure 1-2 As shown, the present invention provides a technical solution: an anti-pressure release energy-saving gas compressor, including a base ring 6, the top of the base ring 6 is fixedly connected to a support rod 8, and the top of the support rod 8 is fixedly connected to There is an anti-pressure relief device 5, and the middle position of the top of the anti-pressure relief device 5 is provided with a pressure storage tank 4, and the top of the pressure storage tank 4 is fixedly connected with a pressurizing device 7, and the top of the pressurizing device 7 The air intake pipe 1 is fixedly connected, and the outer surface of the pressurizing device 7 is fixedly connected with a fixed ring plate 2, and the bottom of the fixed ring plate 2 is fixedly connected to the upper surface of the pressure relief device 5 through the upper support frame 3. The pressurizing device 7 includes an elastic slide bar 76 and a rotating pressurizing plate 72, the bottom of t...

Embodiment 2

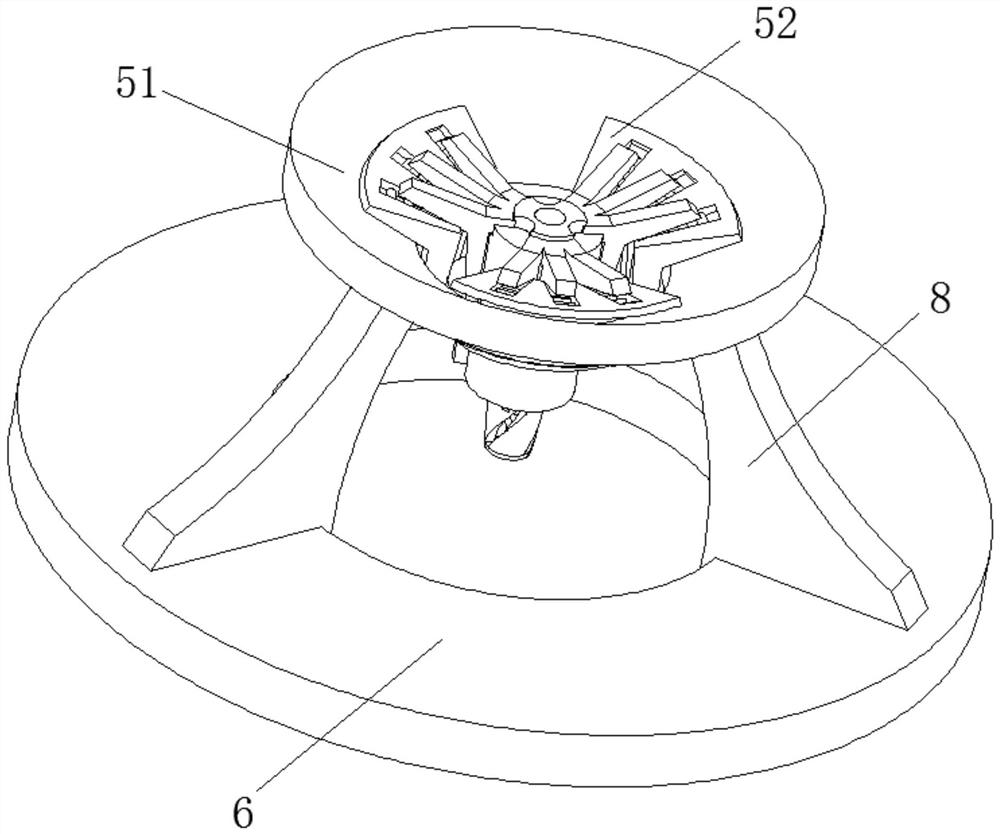

[0042] like Figure 3-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the anti-pressure relief device 5 includes a pressure relief pipe chamber 56, and the side of the upper surface of the pressure relief pipe chamber 56 is fixedly connected with a plastic bifurcation Block 54, the middle of the top of the pressure relief pipe warehouse 56 is fixedly connected with a one-way air valve device 53;

[0043] A seal ring 57 is fixedly connected to the inner wall of the bottom of the pressure relief pipe chamber 56, and an air outlet device 58 is fixedly connected to the inside of the seal ring 57, and an anti-extrusion ring 51 is fixedly connected to the top of the support rod 8. A side extrusion block 52 is fixedly connected to the inside of the anti-extrusion ring 51 .

[0044] The depression on the upper surface of the side extrusion block 52 is provided with a friction block 55, the outer surface of the friction block 55 is adapte...

Embodiment 3

[0051] like Figure 6-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the one-way air valve device 53 also includes an air valve block 531, and the outer surfaces of the air valve block 531 are respectively fixedly connected In the middle of the pressure relief pipe warehouse 56 and the top of the pressure storage tank 4, the transmission rod 533 runs through the air valve block 531 and extends to the outside, and the end of the transmission rod 533 away from the double-layer airtight plate 534 is fixedly connected to the outer top plate 532.

[0052] The bottom between the opposite surfaces of the double-layer airtight plates 534 is provided with a central groove 535, and the top between the opposite surfaces of the double-layer airtight plates 534 is fixedly connected with a plug cover 536, and the upper surface of the plug cover 536 is in contact with the The central groove 535 fits. When the gas valve block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com