Fluid connector

A connector and fluid technology, applied in the direction of couplings, mechanical equipment, etc., can solve problems such as fluid medium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

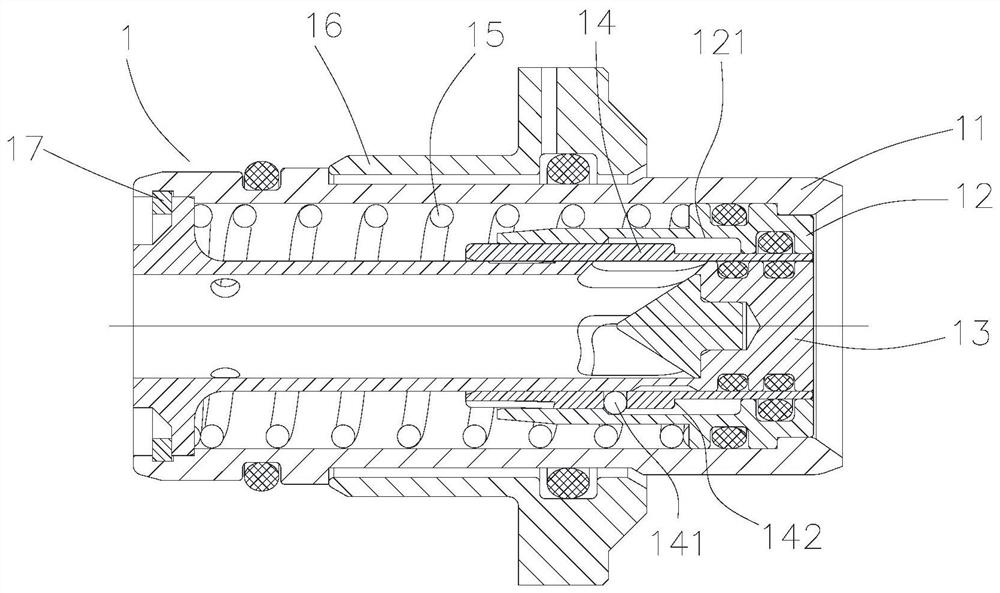

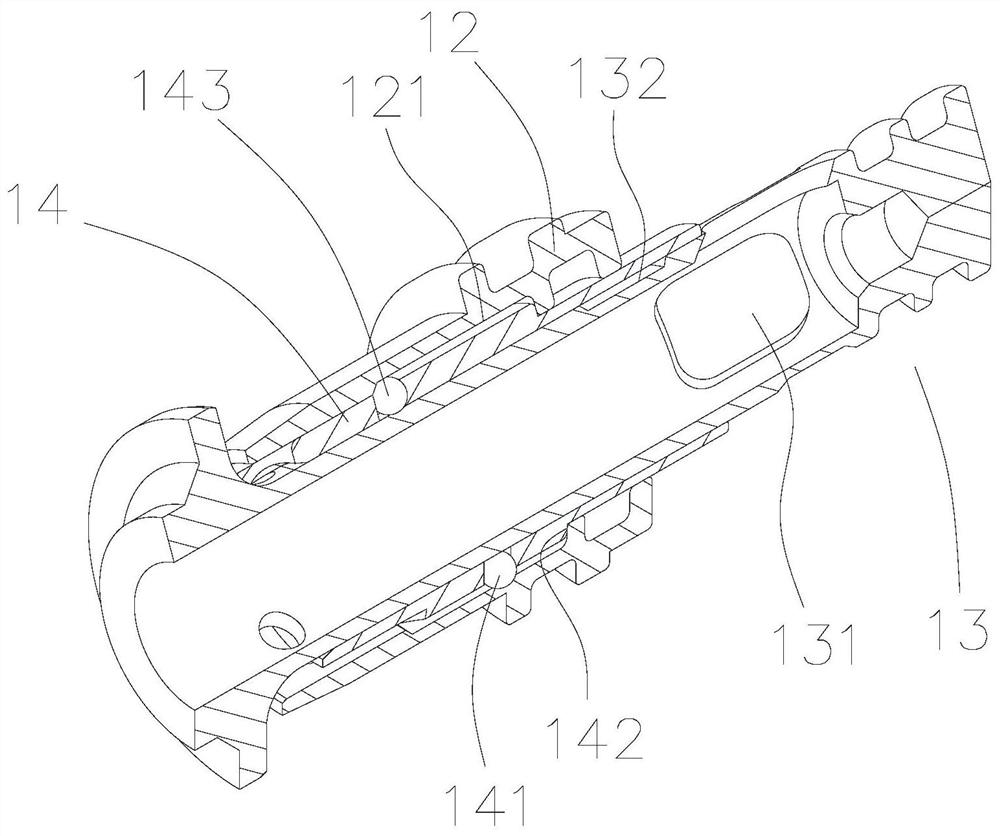

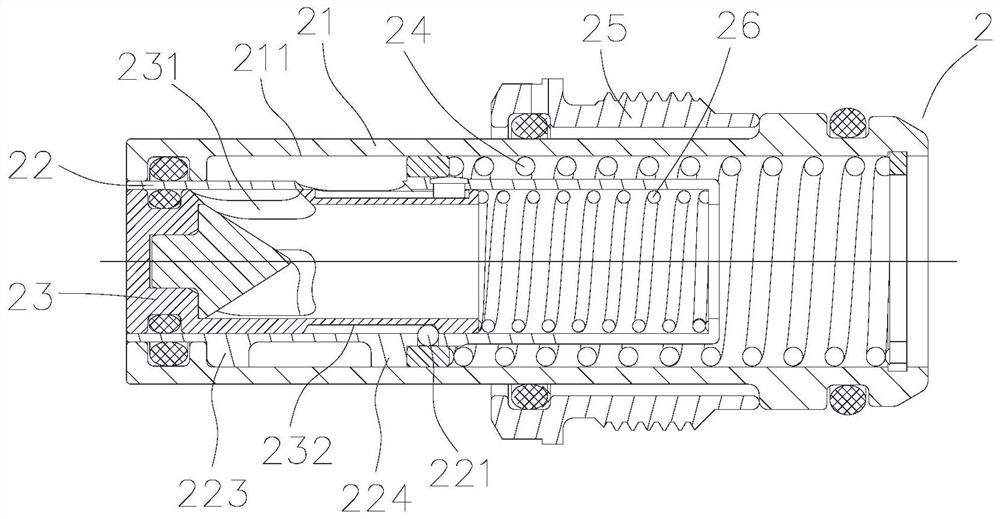

[0025] Such as Figure 1 to Figure 5 As shown, a fluid connector includes a female connector 1 and a male connector 2 that fits into the female connector 1. The female connector 1 includes a female connector sealing sleeve 12 that is slid from outside to inside and a female connector limit sleeve. 14 and the female joint spool 13, the first elastic mechanism and the first axial limit mechanism are arranged in the female joint 1 to make the female joint sealing sleeve 12, the female joint limit sleeve 14 flush with the butt end surface of the female joint spool 13, The internal channel of the female joint spool 13 has a first window 131 in the radial direction on the side, and the female joint limit sleeve 14 blocks the first window 131. The male joint 2 includes a male joint housing 21, a male joint housing 21, and a male joint that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com