Method for formulating insulation and voltage resistance test standard of core packages with gel diaphragms

A technology of dielectric withstand voltage and test standard, which is applied in the direction of testing dielectric strength, measuring electricity, measuring devices, etc., and can solve the problem of inability to guarantee the validity and accuracy of the results of the core-pack dielectric withstand voltage test with gel diaphragm. , to achieve the effect of improving the test effect, good validity and pertinence, and improving the detection power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

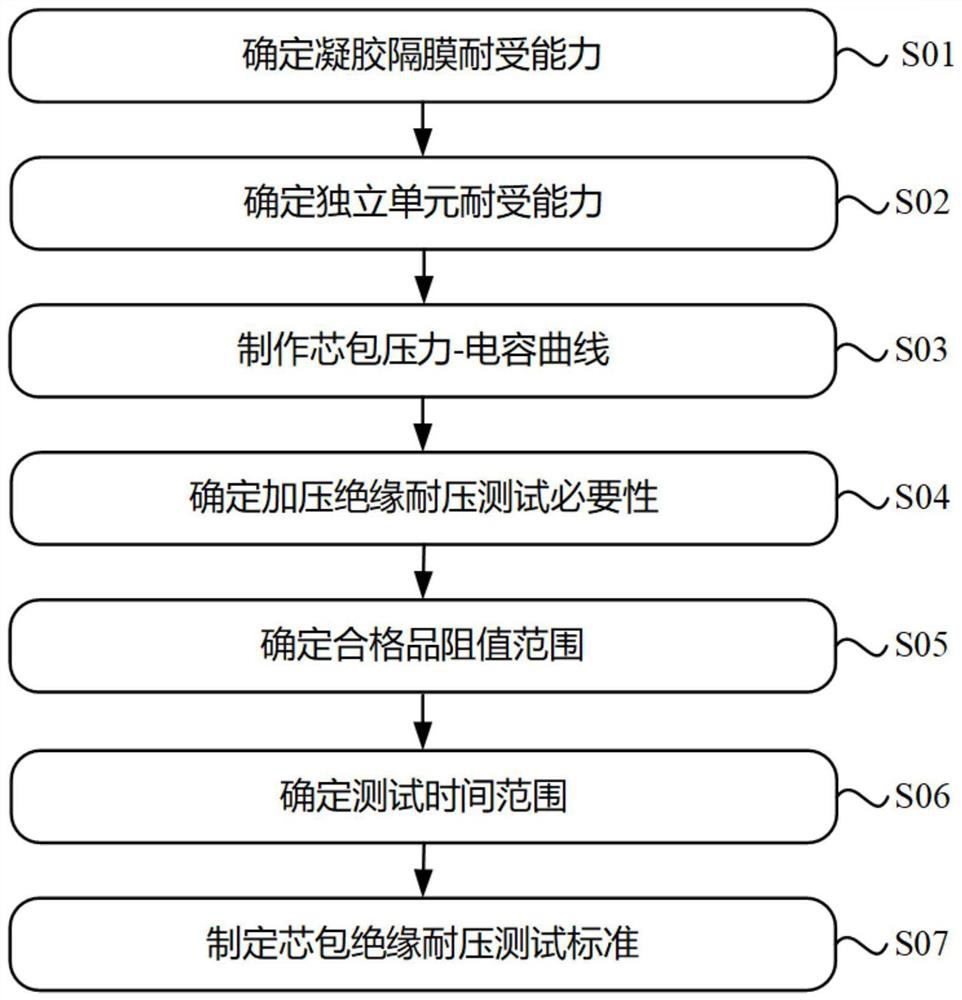

[0032] like figure 1 As shown, a standard formulation method for core-wrapped insulation withstand voltage test with gel diaphragm, including the following steps:

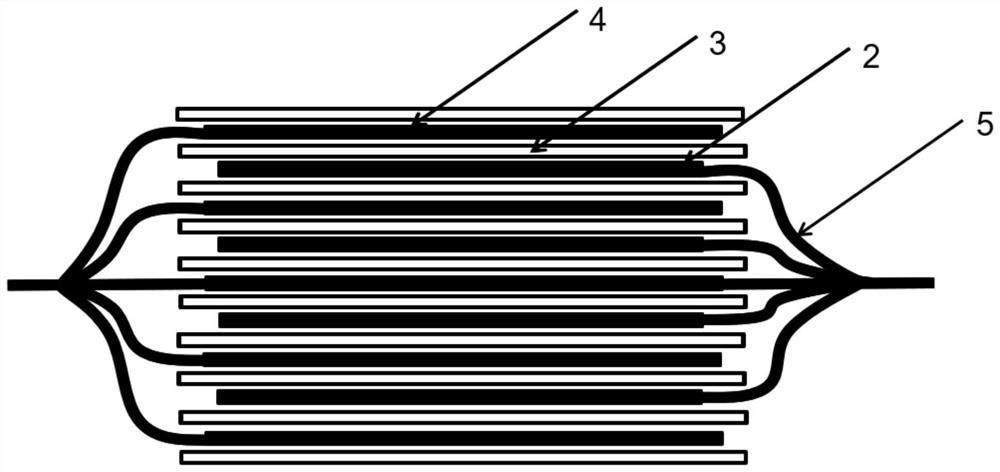

[0033] The first step S01, determination of the tolerance of the gel diaphragm 3: conduct an orthogonal gradient experiment on the gel diaphragm 3 used in the core pack 5, and determine the pressure resistance value of the gel diaphragm 3 and the The pressure and time used in the orthogonal gradient experiment;

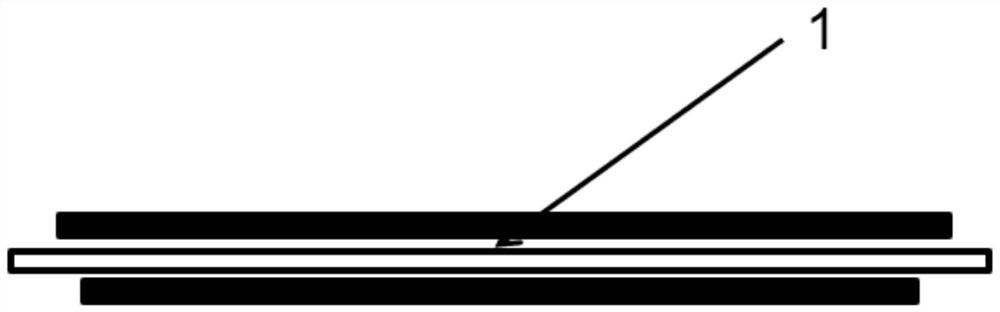

[0034] The second step S02, determination of the tolerance of the independent unit 1: Carry out an orthogonal gradient experiment on the independent unit 1 of the core pack 5, and then take the pressure resistance value of the gel diaphragm 3 in the first step S01 and the independent unit 1 The minimum value in the withstand voltage value of unit 1 is used as the upper voltage limit in the insulation withstand voltage test; the pressure used to reach the upper voltage limit is used as the upper pressure l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com