Heat-resistant tungsten steel milling cutter

A technology of tungsten steel and milling cutters, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of milling cutter corrosion, milling cutter breakage, and affecting the service life of the device, so as to slow down the corrosion rate, prolong the service life, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

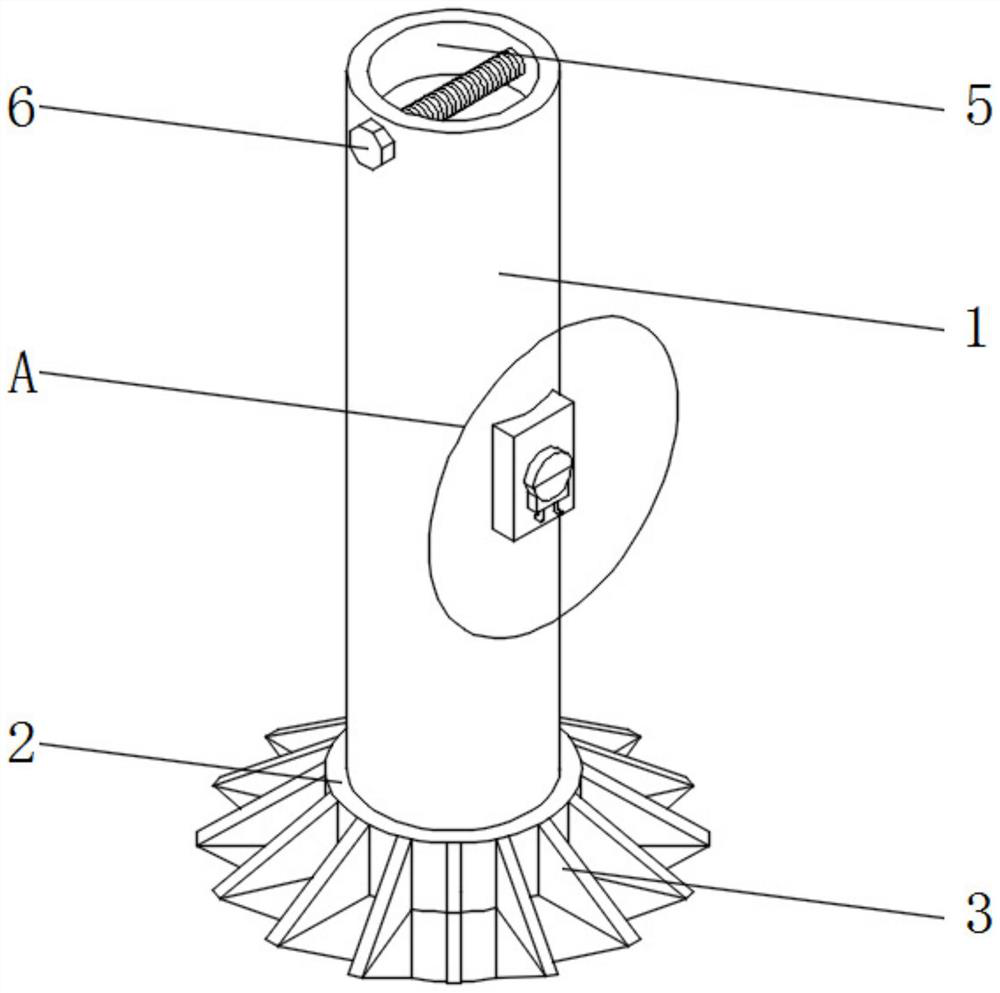

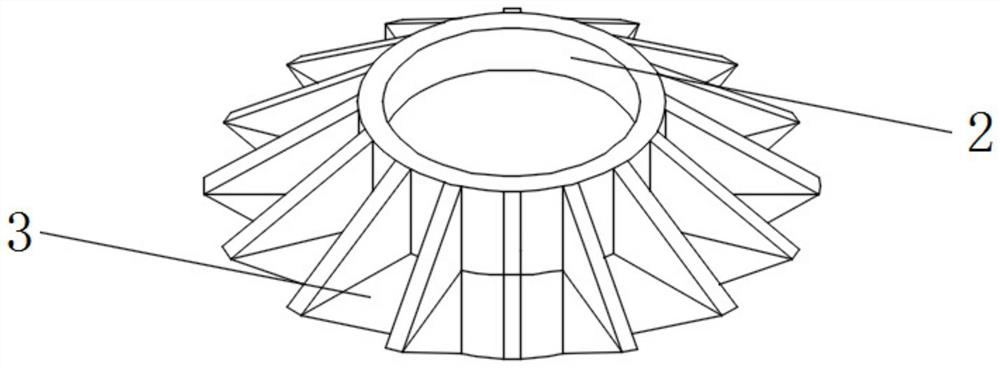

Embodiment 1

[0027] Embodiment 1 includes a connecting rod 1 and a fixing ring 2, the outer surface of the connecting rod 1 is equipped with a fixing ring 2, and the connecting rod 1 is a fixing ring 2 installed on its outer surface and inside, an insertion groove 5, a fixing bolt 7 and a shock absorber Layer 11 provides a fixed point. At the same time, when the insertion groove 5 is connected to the external drive part, driven by the external drive part, the connecting rod 1 transmits the rotational force to the inside of the fixed ring 2, and the fixed ring 2 is its inner and outer surfaces. The installed milling teeth 3 and the cooling interlayer 4 provide fixed points. When the rotational force is transmitted to the inside of the fixed ring 2, the fixed ring 2 transmits the rotational force to the inside of the milling teeth 3. Several milling teeth are installed on the outer surface of the fixed ring 2. 3. The milling tooth 3 rotates under the drive of the fixed ring 2. When the millin...

Embodiment 2

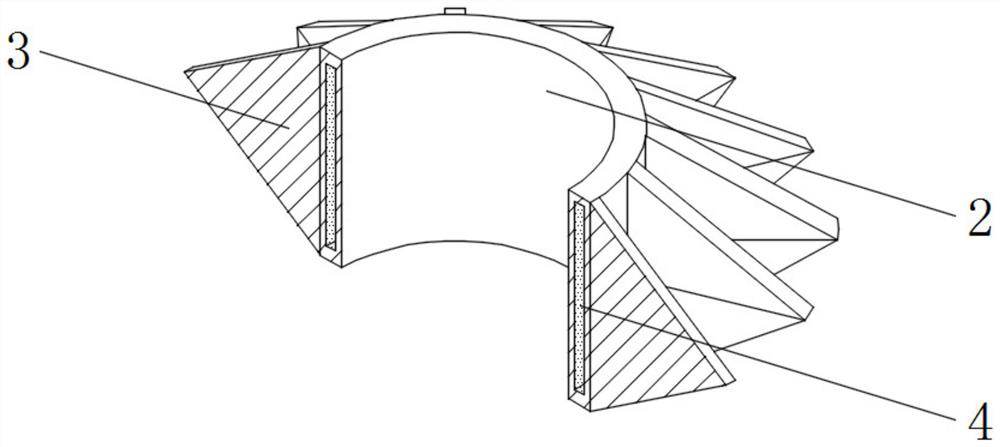

[0029] Embodiment 2 includes a fixed ring 2 and a cooling interlayer 4. The inner inner wall of the fixed ring 2 is arranged with a cooling interlayer 4. When the milling cutter is in contact with the material, the milling teeth 3 rub against the material to generate a large amount of heat. At the same time, the fixed ring 2 Under the action of heat transfer, the cold water inside the internal cooling interlayer 4 absorbs the heat on the outer surface of the milling tooth 3, thereby preventing the milling tooth 3 from being deformed due to the high temperature of the outer surface, thereby improving the service life of the device.

[0030] as attached figure 1 and Figure 5 As shown, a heat-resistant tungsten steel milling cutter;

Embodiment 3

[0031] The third embodiment includes a connecting rod 1 and a fixing bolt 7, the outer surface of the connecting rod 1 is equipped with a fixing bolt 7, and the fixing bolt 7 is located above the fixing ring 2, and the fixing bolt 7 provides fixing for the power supply 8 installed on its outer surface. At the same time, when the electric energy is transmitted to the inside of the fixed bolt 7 through the anode wire 9, the fixed bolt 7 conducts the electric energy to the whole milling cutter, supplements the electrons lost by the metal due to oxidation, reduces the metal ions to metal atoms, and slows down the corrosion rate of the milling cutter , to improve the service life of the milling cutter, a power supply 8 is installed on the outer surface of the fixing bolt 7, and the electric energy is transmitted to the inside of the anode wire 9 through the button battery inside it, and the anode wire 9 is installed on the bottom of the power supply 8, and the anode wire 9 Connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com