Plugging combined type movable house

A prefab house and combined technology, applied in the field of prefab houses, can solve the problems of large components, unfavorable transportation, cumbersome assembly or disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

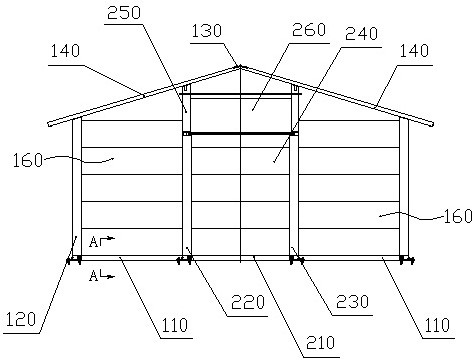

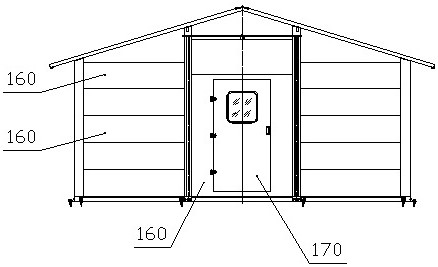

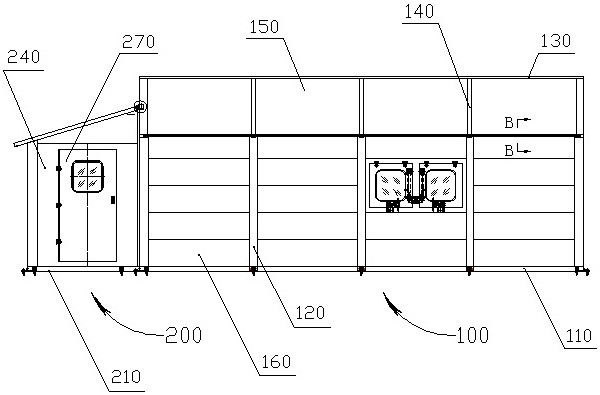

[0028] see figure 1 - Figure 5 , the plug-in combined movable house of the present invention includes a main movable house 100 and a door bucket house 200 connected with the main movable house. The main movable house has a horizontal main geosphere beam 110, and vertical Straight up main body column 120, the top of main activity room has main body ridge plate 130, is connected with downwardly inclined main body slideway 140 between main body ridge plate and corresponding main body column top, inserts between adjacent main body slideways. The main body panel 150 is connected, and the angle of the main body panel and the main body slideway is inclined downward. The main body wall panel 160 is inserted between the adjacent main body columns, and the end of the main body panel is lapped on the top of the corresponding main body wall panel. A main body access door 170 is provided on the main body wall plate inserted between two adjacent main body uprights. The door bucket house ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com