Pre-buried guide pipe assembly suitable for tunnel curtain grouting with extra-high water pressure and pre-burying method

A curtain grouting and guide tube technology, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of wall damage, different spatial angles, different positions, etc., and achieve the effect of saving steel and reducing damage to its own strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

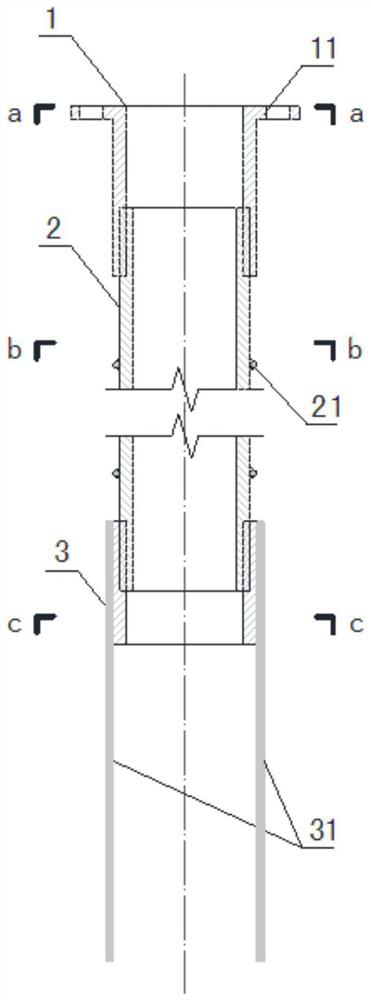

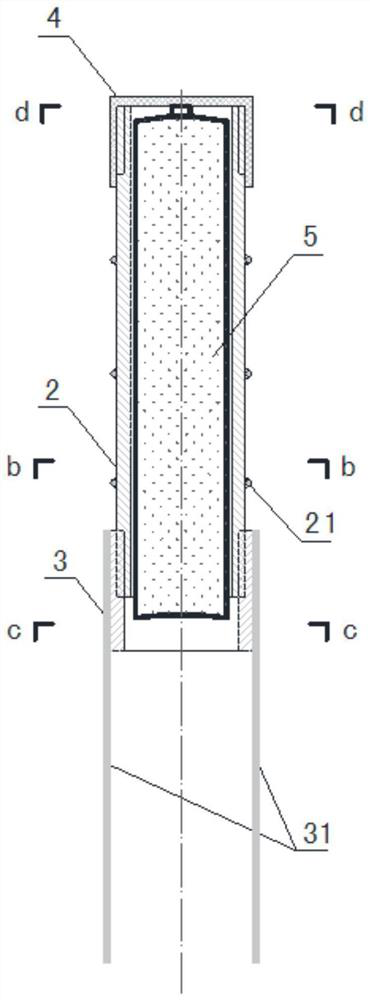

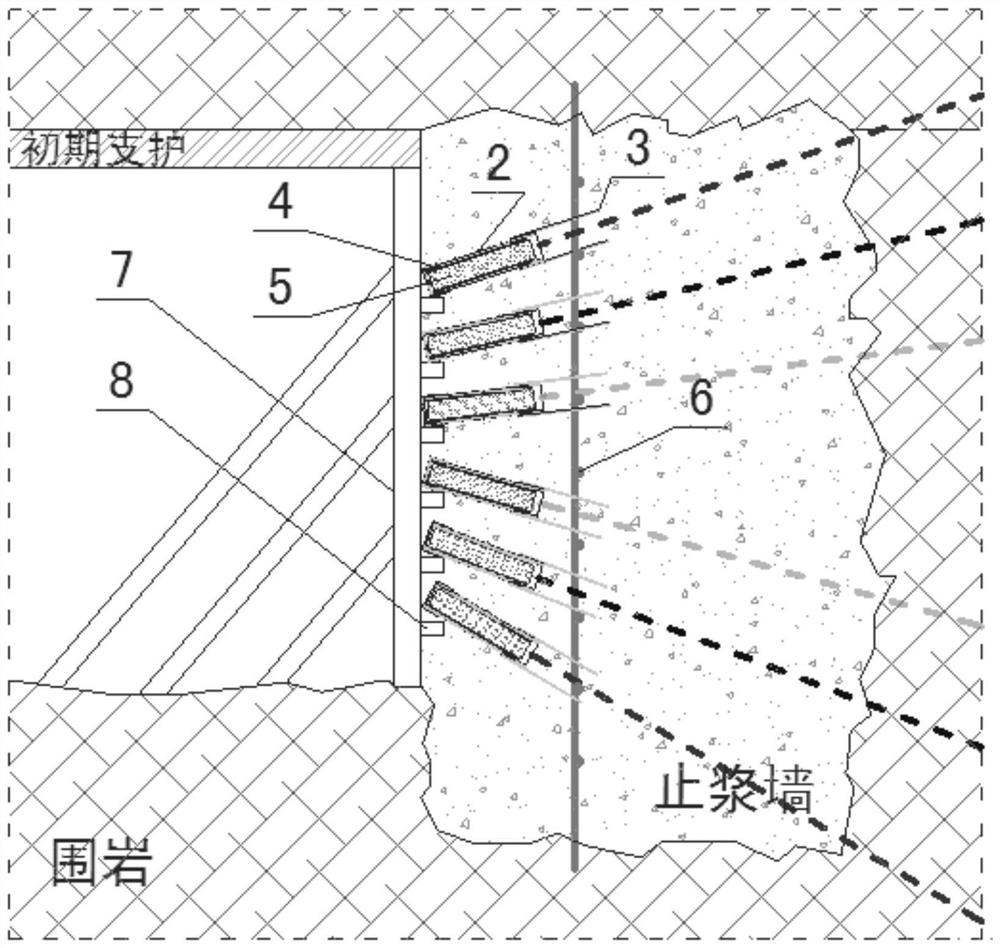

[0031] The present invention is a pre-embedding method for pre-embedded guide pipe assembly suitable for super-high water pressure tunnel curtain grouting, which is suitable for tunnel excavation process, encountering bad geology, high-pressure water gushing, endangering construction safety, and systematic advance is required Situation of curtain grouting construction. Among them, the construction of the grout stop wall and the installation of the guide pipe are the prerequisites for the success or failure of the curtain grouting. And use the pre-embedded guide pipe and pipe head 1 to clamp and wrap the pre-embedded guide pipe in the grout-stop wall, such as figure 1 and 2 Shown:

[0032] The pre-embedded guide tube includes a pipe body 2, a pipe tail 3, a pipe cap 4 and a filling bag 5, and the pipe body 2 and the pipe tail 3 are threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com