Hole sealing device for monitoring grouting pressure of grouting anchor rods

A technology of grouting anchor rods and grouting pressure, which is applied in the installation of anchor rods, mining equipment, earthwork drilling and mining, etc. It can solve the problems that the grouting effect cannot be realized and the sealing effect cannot be improved, so as to improve the grouting effect, The effect of enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

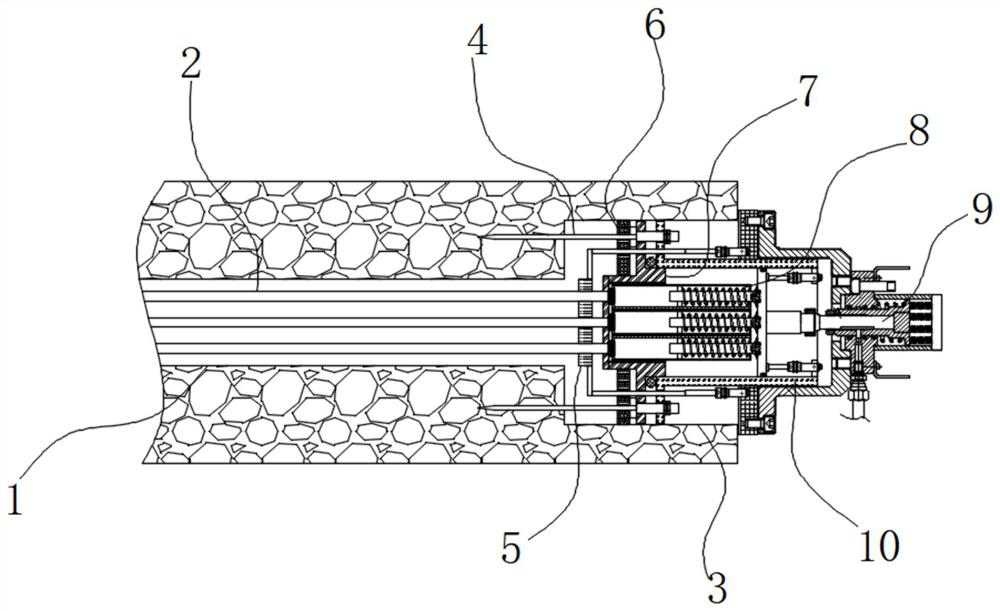

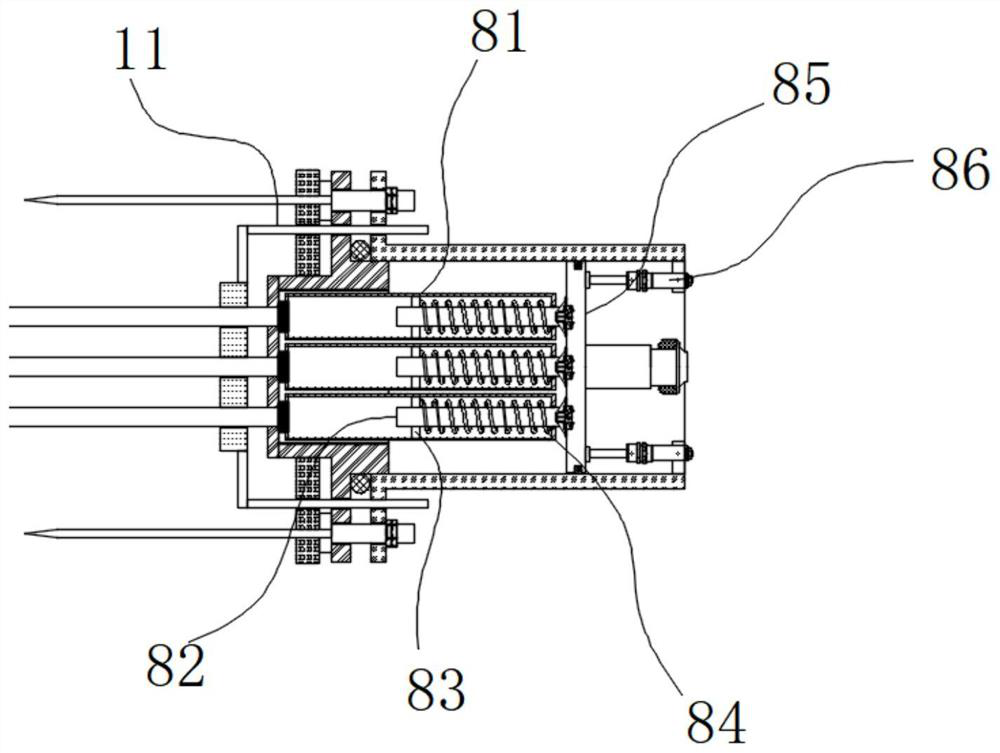

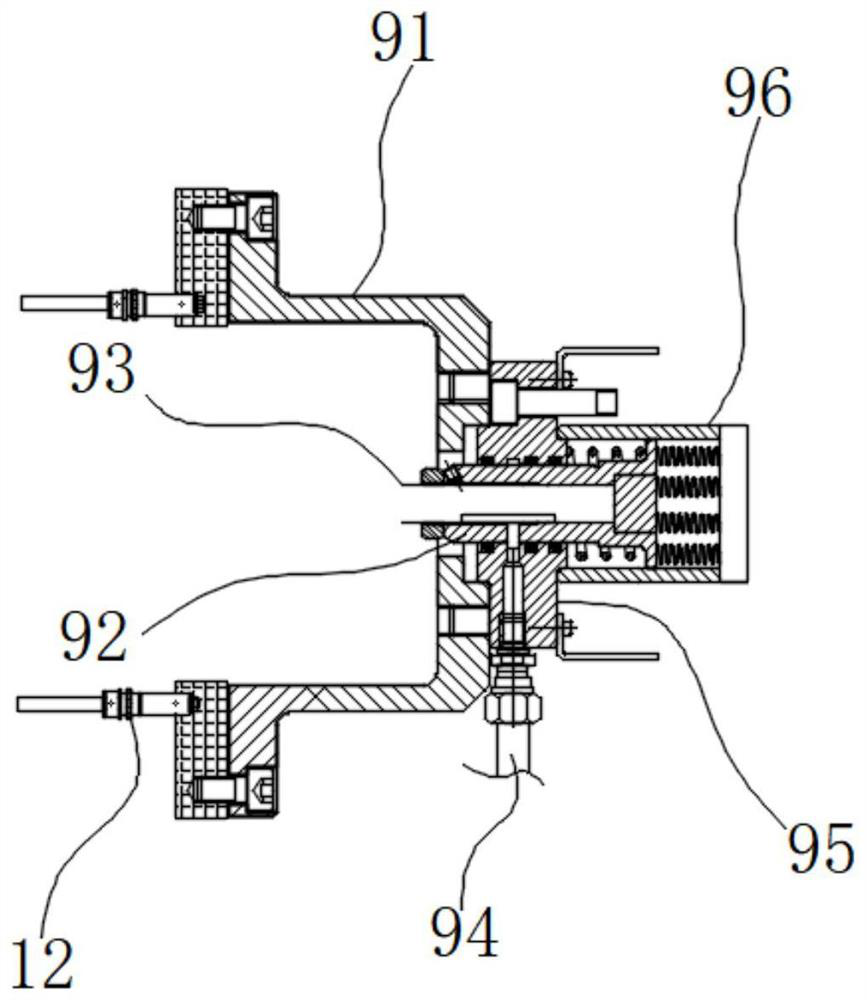

[0037] see Figure 1~3 , the invention provides a sealing device for monitoring the grouting pressure of a grouting bolt, comprising:

[0038] The first sealing disc 5 is movably arranged at the orifice position of the grouting hole 1, so that the grouting hole 1 is sealed after the grouting is finished, and in the first sealing disc 5 A plurality of first grouting anchor rods 2 are arranged through the sealing slide;

[0039] The second sealing disk 6 is fixed in the reaming 3, so that the reaming 3 is sealed during the grouting process;

[0040] The reaming hole 3 is arranged at the orifice position of the grouting hole 1, and the diameter of the reaming hole 3 is larger than the diameter of the grouting hole 1;

[0041] The first grouting anchor 2 is pulsed by a pulsed grouting component 8 .

[0042] That is to say, in the implementation process, the second sealing disc 6 can be used to seal the reaming hole 3 during the grouting process, and the first sealing disc 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com