Steam-doped super-cavitation spray noise suppression device for thermostatic expansion valve

A thermal expansion valve and noise suppression technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of large injection noise and large overall sound power, and achieve low maintenance costs, overall noise level suppression, and bubble bursting Effect of Noise Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and implementation the present invention will be further described

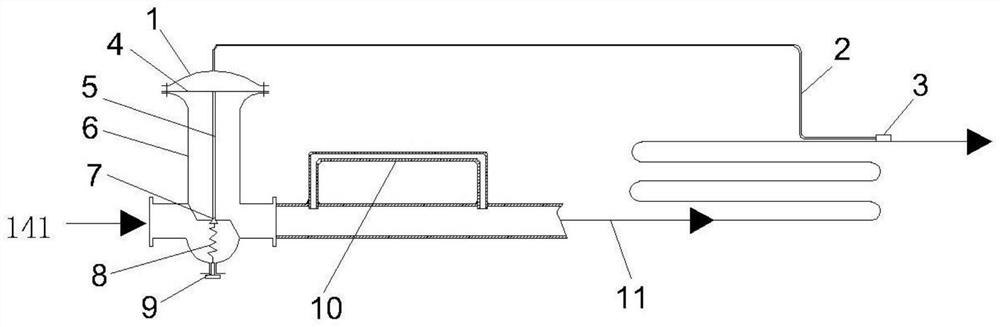

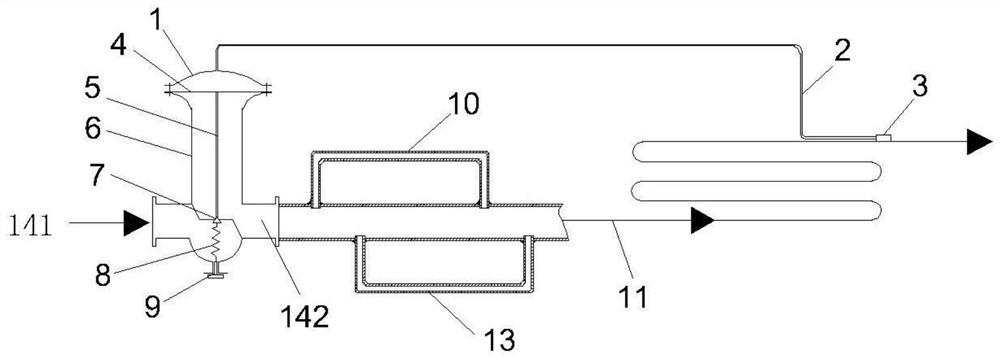

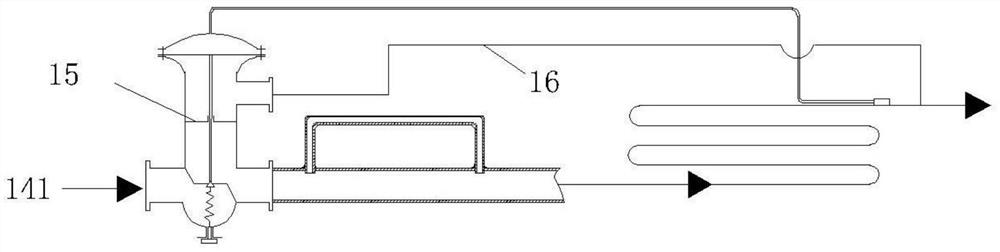

[0031] see Figure 1-4, the noise suppression device for steam-mixed supercavitation injection of a thermal expansion valve includes a thermal expansion valve, a bypass capillary, and an evaporator inlet pipe; wherein the thermal expansion valve includes an internally balanced thermal expansion valve and an externally balanced thermal expansion valve.

[0032] see Figure 1-2 , the described noise suppression device for steam-mixed supercavitation injection of thermal expansion valve comprises: inner balance thermal expansion valve bonnet 1, thermal expansion valve temperature control capillary 2, temperature control temperature sensing package 3, thermal expansion valve diaphragm 4. Thermal expansion valve diaphragm push rod 5, thermal expansion valve body 6, thermal expansion valve spool 7, spring 8, adjustment screw 9, bypass capillary a and bypass cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com