Noise Suppression Device for Two-way Expansion Valve Mixed Steam Supercavitation Injection

A two-way expansion valve and noise suppression technology, applied in refrigerators, refrigeration components, chemical industry, etc., can solve the problems of large injection noise and large overall sound power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

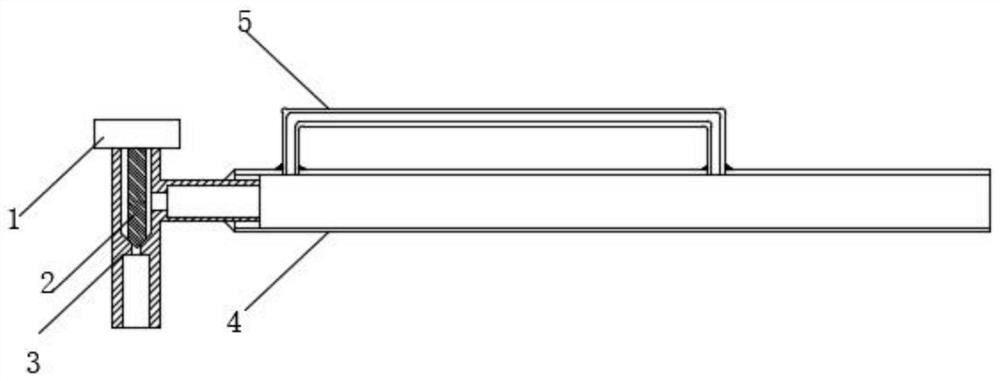

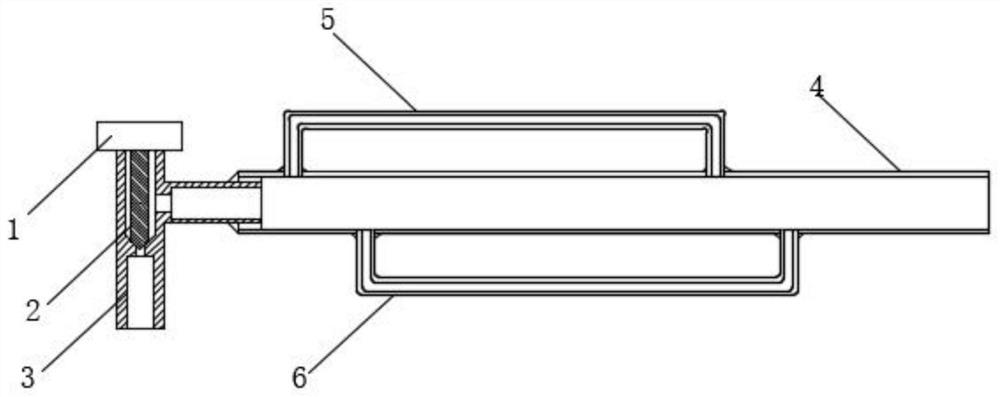

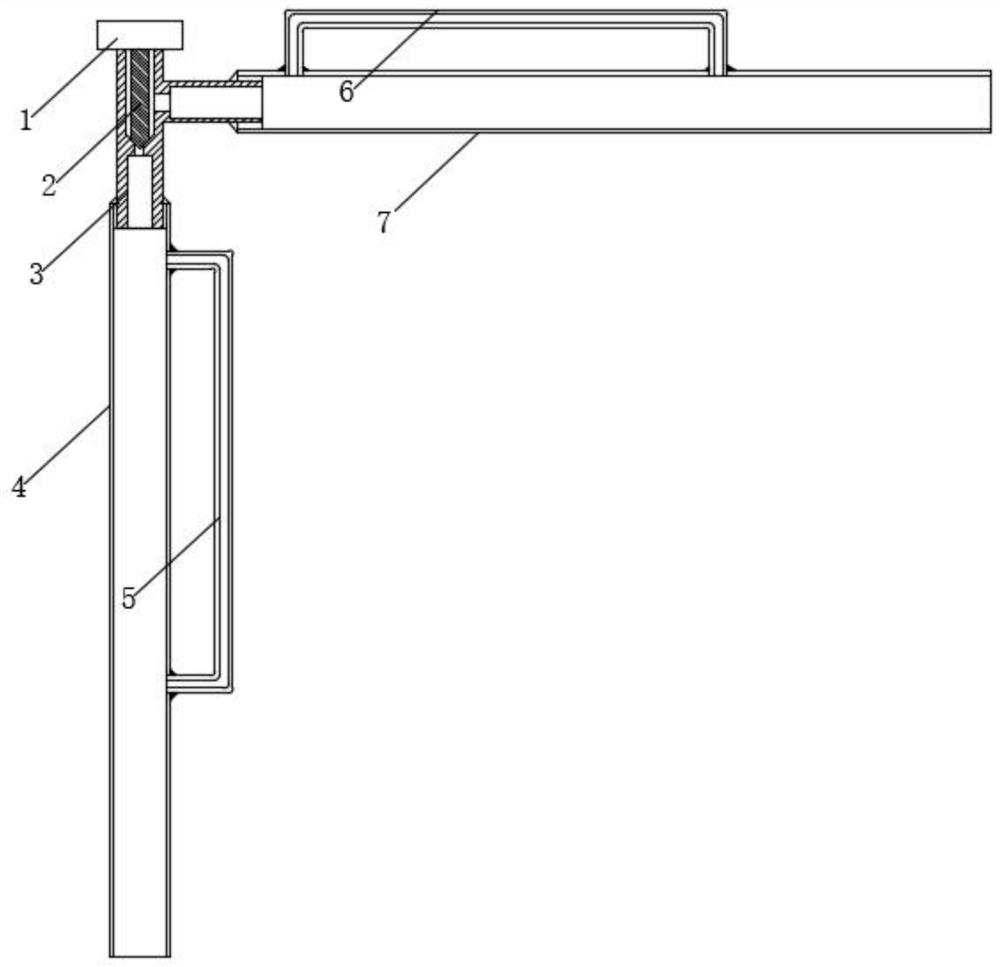

[0022] The following further description of embodiments of the present invention in conjunction with the accompanying drawings and

[0023] See figure 1 The bidirectional expansion valve ultra-doped vapor cavitation jet noise suppressing means comprises an electronic expansion valve coil 1, an electronic expansion valve stem 2, the electronic expansion valve body 3, the evaporator inlet transition duct 4, the bypass capillary tube a, bypass a capillary outer diameter of 1.8-2.5mm, an inner diameter of 0.6-0.7mm, the bypass capillary tube a total length of 200mm, a bypass capillary tube is inserted into the evaporator inlet pipe 4 the distal end of the transition length of 10mm, is inserted from the front end of the electronic expansion valve an outlet from the valve body 3 is 10mm; bypass capillary tube is inserted into a length of the evaporator inlet transition tube rear end 4 of 10mm, the distance from the rear end of the inserted electronic expansion valve outlet 3 of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com