Intelligent CMM probe system configuration method

A technology of intelligent configuration and measuring head, which is applied in the direction of measuring device, electromagnetic measuring device, point coordinate measurement, etc., can solve the problem of lack of intelligent configuration method of CMM probe system, etc., and achieve the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

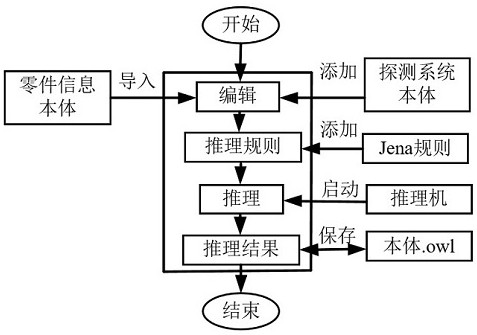

Method used

Image

Examples

Embodiment Construction

[0060] The following is a specific example of the present invention, showing the automatic generation of the detection system configuration scheme. However, the present invention is not limited to these examples.

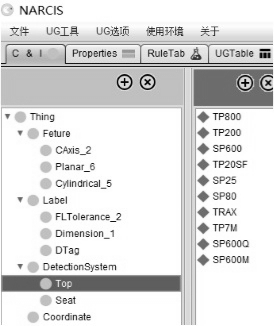

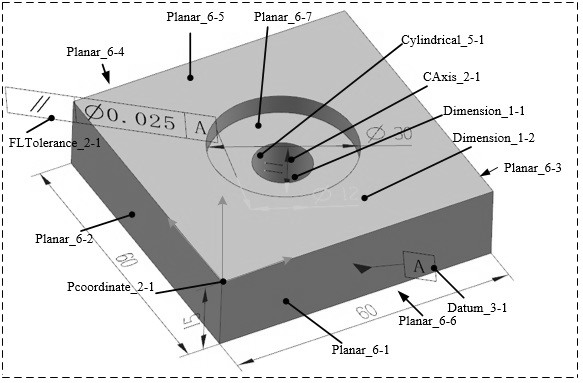

[0061] Step 1: Establish the 3D model of the part in the software UG10.0 based on MBD technology, and the individual and attribute marks are shown in 2.

[0062] After step 1 is completed, proceed to step 2;

[0063] Step 2: According to measurement knowledge, obtain the probe and head models of commonly used probing systems.

[0064] After step 2 is completed, proceed to step 3;

[0065] Step 3: Build a measurement ontology including individuals and attributes, such as figure 1 shown. Including: MGDE individuals: CAxis_2-1 and CPlanar_3; TTRS surface individuals: Cylindrical_5-1, Planae_6-1; marked individuals: FLTolerance_2-1, Dimension_1-1, Datum_3-1; according to the dimension Tl={zhijing, 12 } and geometric tolerance annotation To={Parallelism, 0.025, A} co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com