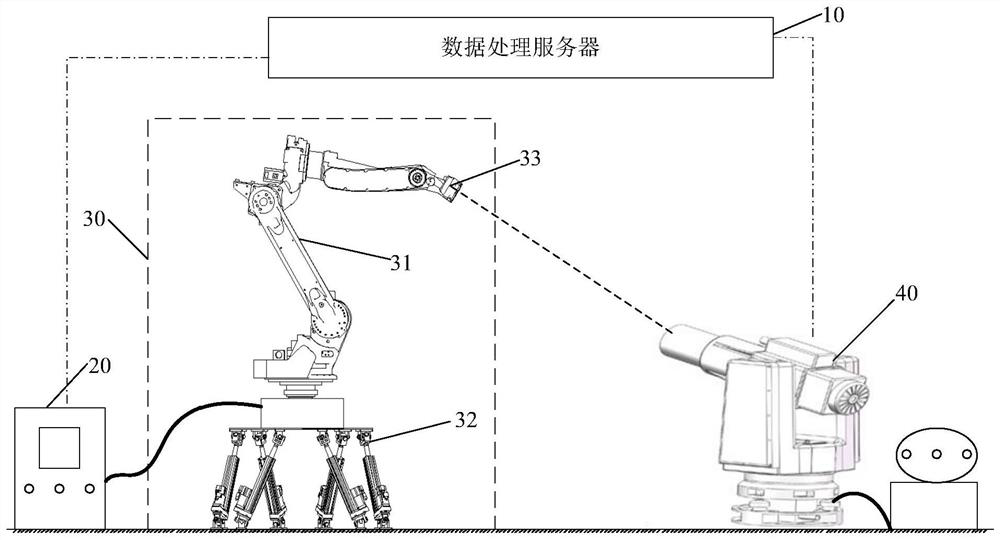

System and method for detecting tracking performance of optical measurement equipment of movable platform

A technology of optical measurement equipment and detection system, which is applied in the field of tracking performance detection system of optical measurement equipment on moving platforms, and can solve problems such as inability to detect tracking performance, increased cycle and development costs, and blind spots in position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

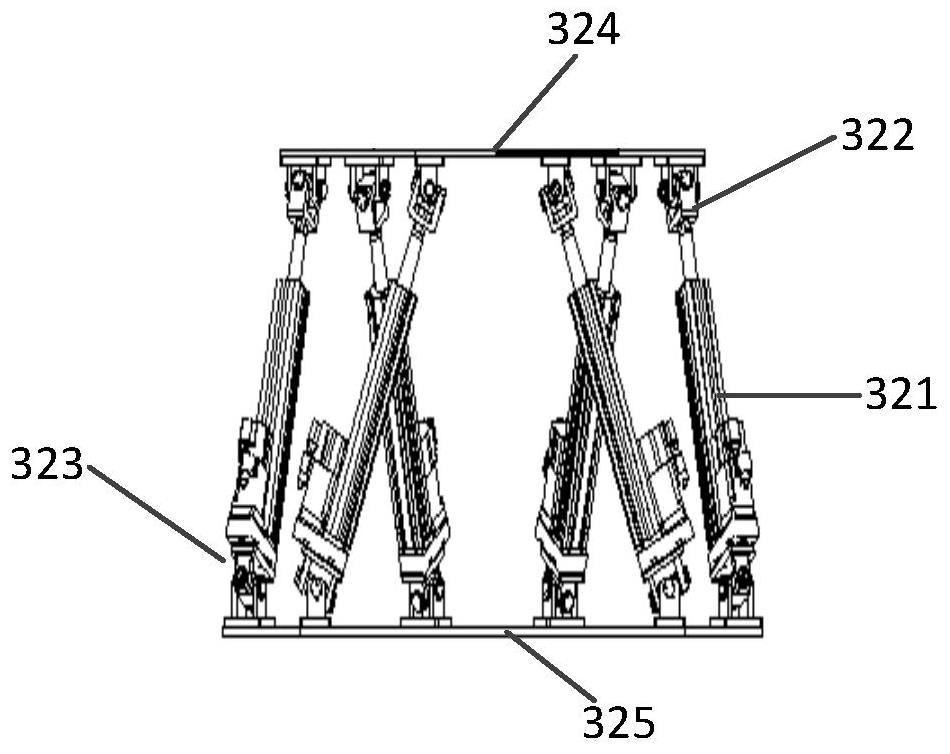

[0045] On the basis of Embodiment 1, this embodiment provides a specific implementation manner for the data processing server 10 to generate detection platform data. This embodiment takes a 6-DOF parallel robot as an example for illustration, including:

[0046] Determine the space velocity Jacobian matrix of a 6-DOF parallel robot.

[0047] According to the given value of the motion velocity of each joint in the 6-DOF parallel robot and the space velocity Jacobian matrix, the space velocity of each joint of the 6-DOF parallel robot is determined.

[0048] Among them, the space velocity Jacobian matrix of the 6-DOF parallel robot is determined by the following method:

[0049] Please refer to Figure 4 , Figure 4 It is a schematic diagram of the relationship between the motion variable and the coordinate system of a 6-DOF parallel robot. According to the screw theory and the spiral motion equation, the Jacobian matrix of the 6-DOF parallel robot is derived. express:

[00...

Embodiment 3

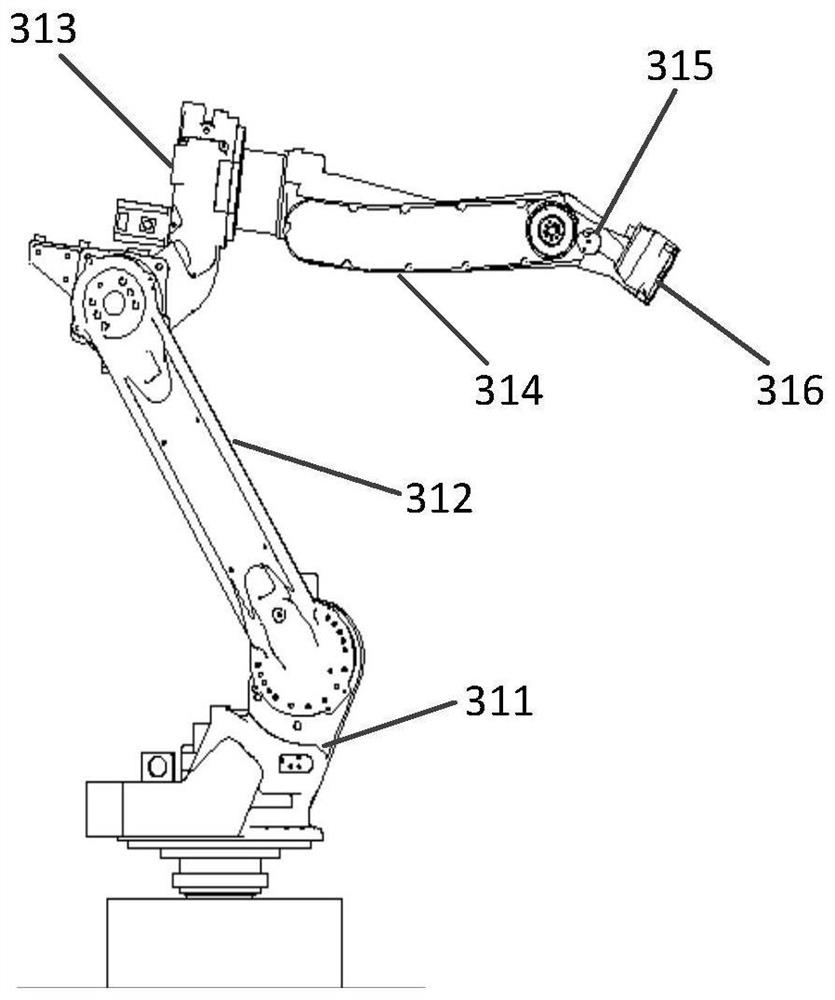

[0080] On the basis of Embodiment 1, this embodiment provides a specific implementation manner in which the data processing server 10 generates the motion data of the detection platform. This embodiment takes a 6-DOF serial manipulator as an example for illustration, including:

[0081] Determine the space velocity Jacobian matrix of a 6-DOF tandem manipulator.

[0082] According to the given value of the motion velocity of each joint in the 6-DOF series manipulator and the space velocity Jacobian matrix, the space velocity of each joint of the 6-DOF series manipulator is determined.

[0083] Among them, to determine the space velocity Jacobian matrix of the 6-DOF series manipulator, it needs to be determined in the following way:

[0084] Please refer to Figure 5 , Figure 5 It is a schematic diagram of the relationship between the motion variable and the coordinate system of the 6-DOF series manipulator. According to the screw theory, the connection coordinate system {M} ...

Embodiment 4

[0120] According to Embodiments 1, 2 and 3, it can be seen that the detection platform in the detection system provided by the embodiment of the present invention includes a 6-degree-of-freedom serial robot and a 6-degree-of-freedom parallel robot, and the 6-degree-of-freedom serial robot is used to simulate the actual optical motor. According to the motion characteristics of the target, the 6-DOF parallel robot simulates the motion posture of the moving platform in all directions, so the detection platform has the characteristics of strong nonlinearity, time deformation and high coupling. In the embodiment of the present invention, the space velocity Jacobian matrices of the 6-DOF serial manipulator and the 6-DOF parallel robot are respectively established, and then the motion postures of the 6-DOF serial manipulator and the 6-DOF parallel robot are fused to complete the normalization of the detection system. Coordinate transformation to realize high-precision positioning and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com