Adjustable power cable hoisting device

A technology of power cables and hoisting devices, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as low construction efficiency, low safety, and large hook shaking, so as to improve work efficiency and safety, and avoid large-angle bending The effect of folding and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

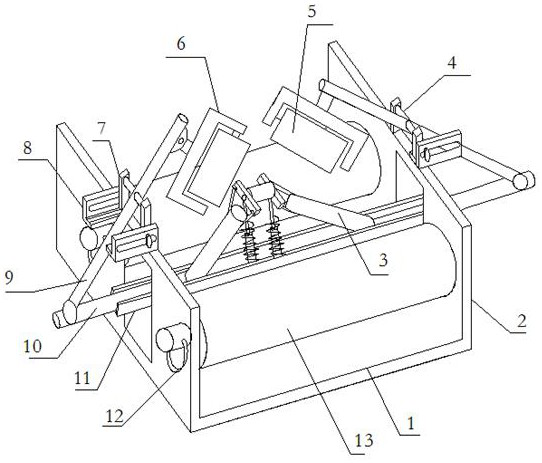

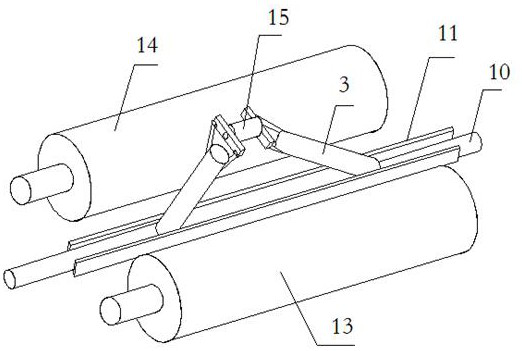

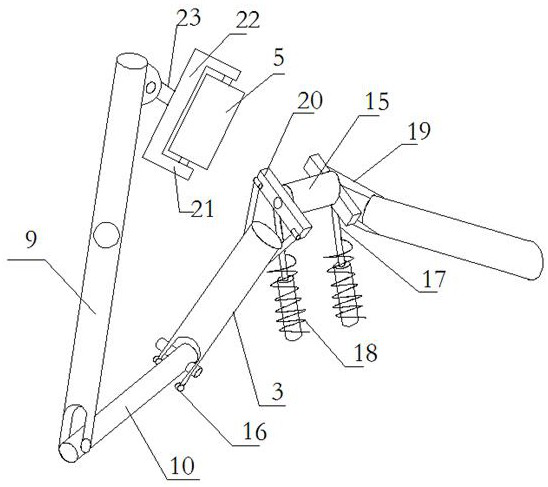

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0017] Such as Figure 1-3 As shown, an adjustable power cable hoisting device includes a base plate 1, side plates 2 are vertically arranged on the left and right sides of the base plate 1, suspension rings 12 are arranged on the side plates 2, and the left and right side plates 2 are arranged side by side The spacer frame is provided with a front roller shaft 13 and a rear roller shaft 14 which can rotate axially, and the bottom plate 1 between the front roller shaft 13 and the rear roller shaft 14 is provided with a slide rail 11 extending left and right, and the middle part of the slide rail 11 There are two telescopic columns 17 spaced apart vertically, and the tops of the two telescopic columns 17 extend upward from the gap between the front roller shaft 13 and the rear roller shaft 14 to the top of the front roller shaft 13 and the rear roller shaft 14, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com