Transmission and meshing clutch

A transmission and clutch technology, applied in the direction of clutches, clutches, mechanical drive clutches, etc. that mesh with each other, can solve the problems of shifting shock and abnormal noise, internal cycle torque increase, and inclination that cannot be reduced, so as to reduce the speed change Shock and abnormal noise, the effect of reducing shock and abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] [summary of transmission]

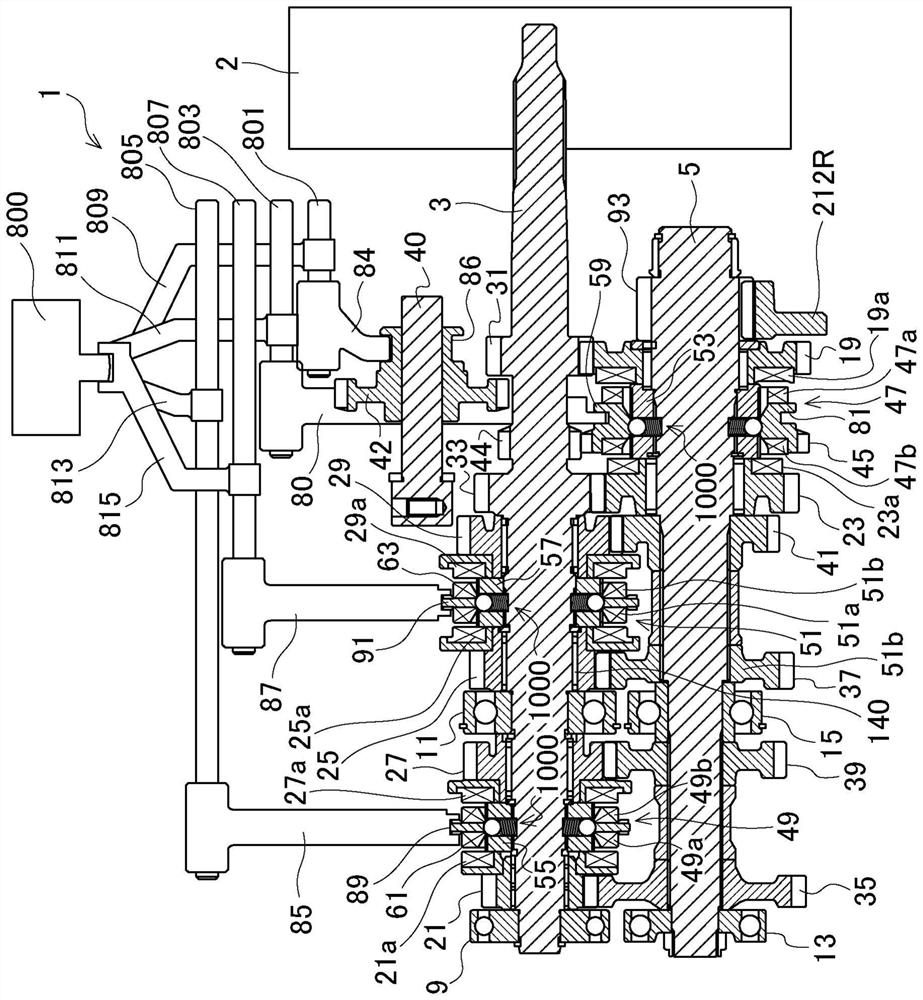

[0080] figure 1 It is a schematic sectional view showing a seamless shift transmission according to Embodiment 1 of the present invention.

[0081] Such as figure 1 As shown, the transmission 1 includes a solid main shaft 3 , a counter shaft 5 , and an idler shaft 40 as torque transmission members. These main shaft 3 and counter shaft 5 are rotatably supported by a transmission case (not shown) by bearings 9 , 11 , 13 , 15 and the like. The idler shaft 40 is fixed on the side of the transmission case.

[0082] In the above-mentioned main shaft 3 and countershaft 5, a first-speed gear 19, a second-speed gear 21, a third-speed gear 23, a fourth-speed gear 25, a fifth-speed gear 27, and a sixth-speed gear 29 are supported in appropriate positions as multi-stage gears. Gear change.

[0083] The first gear 19 and the third gear 23 on the above-mentioned auxiliary shaft 5 mesh with the output gears 31 and 33 of the main shaft 3, and the second...

Embodiment 2

[0222] Figure 20 , Figure 21 Example 2 is shown. Figure 20 It is a schematic configuration diagram of a system for canceling shifting. Figure 21 It is a flowchart for performing shift cancellation.

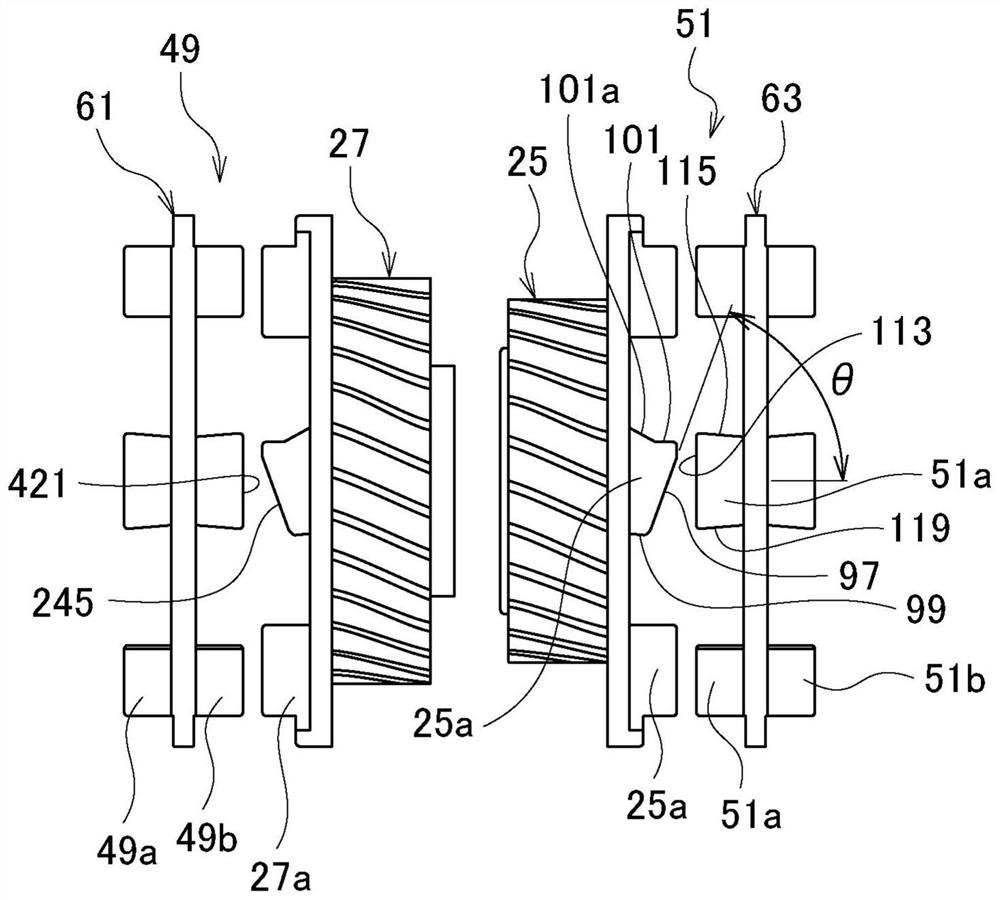

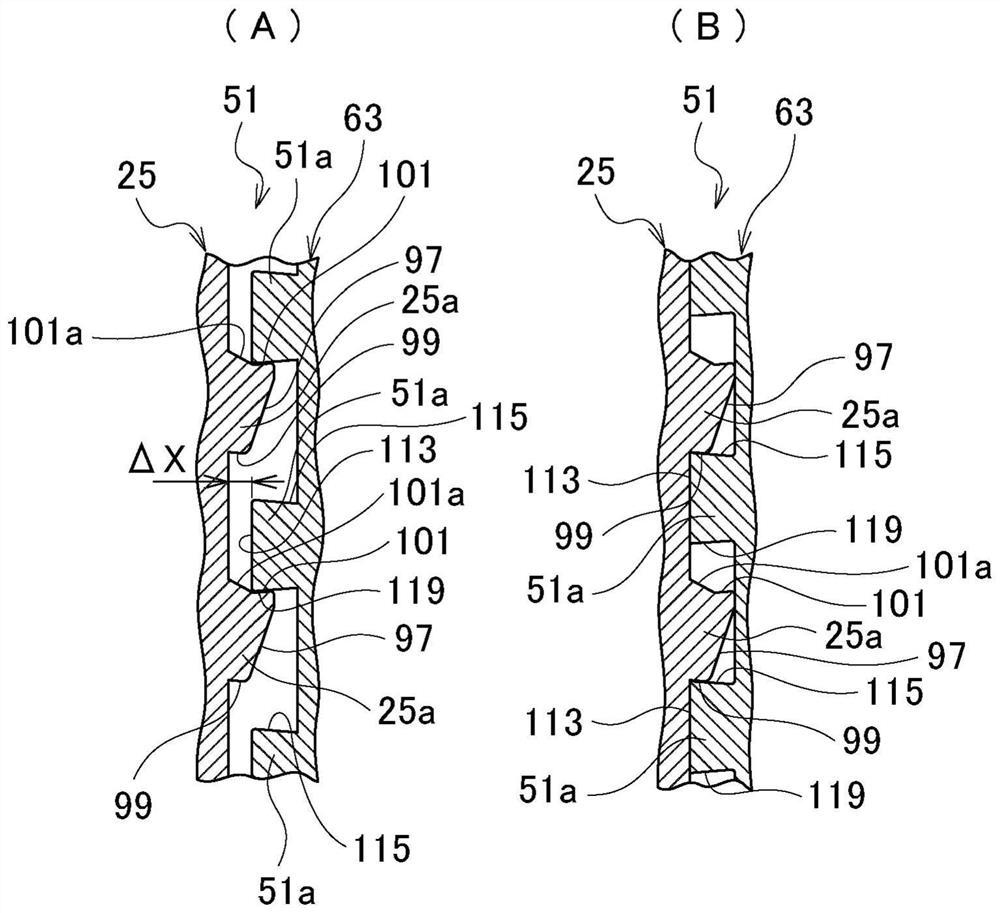

[0223] Figure 20 Indicates the action of the low-level meshing teeth when the high-level and low-level meshes at the same time. For example, the relationship between the clutch sleeve 63 and the fourth speed gear 25 is shown in the third meshing clutch 51 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com