Novel stem cutting machine device

A stem cutting machine, a new type of technology, applied in the treatment of tobacco, tobacco, application, etc., can solve the problems of unreasonable local structure of the stem cutting machine, damage to the bakelite ring gear, frequent failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

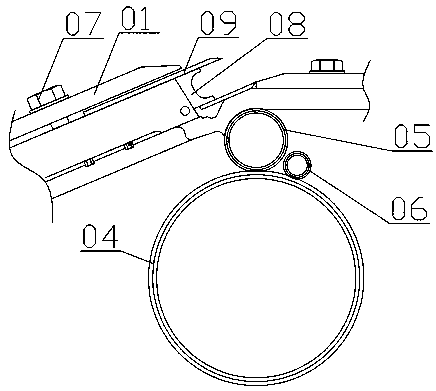

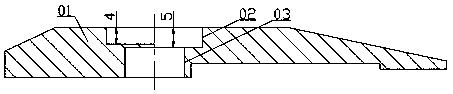

[0022] A new type of stem cutter device, including a pressure knife plate 01, a bakelite ring gear 04, a planetary wheel 05, a driving wheel 06, a compression screw 07, and a knife edge seat 08. The pressure knife plate 01 has a No. 1 installation hole 02 inside, The bottom of No. 1 installation hole 02 has No. 2 installation hole 03. The cantilever length of pressure knife plate 01 is 86.5mm. The left side of 02, the right side of the pressure plate 01 is connected to the blade 09, the bottom of the blade 09 is connected to the knife edge seat 08, the right side of the knife edge seat 08 is connected to the planetary wheel 05, the lower part of the planetary wheel 05 is connected to the bakelite ring gear 04, and the bakelite tooth The ring 04 meshes with the planetary gear 05, the right side of the bakelite ring gear 04 is connected to the driving wheel 06, the bakelite ring gear 04 is meshed with the driving wheel 06, and the pressure angle between the bakelite ring gear 04 ...

Embodiment 2

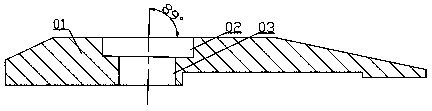

[0029] The No. 1 installation hole 02 is an inclined hole, the bottom surface of the No. 1 installation hole 02 is higher on the left side and the right side is lower. The angle between the center line of the No. 1 installation hole 02 and the top surface of the pressure knife plate 01 is 89° to ensure the installation of the compression screw After 07, the compression screw 07 is in contact with the left end of No. 1 installation hole 02, and the right end is suspended, so that there is a certain gap between the pressure plate 01 and the knife edge seat 08, the cantilever of the pressure plate 01 is changed from 119mm to 86.5mm, and the pressure plate 01 is deformed The amount is reduced from 0.7586mm to 0.285mm, reducing the pressure of the knife-edge seat 08 on the planetary gear 05, thereby reducing the meshing force between the planetary gear 05 and the bakelite ring gear 04, reducing the wear of the bakelite ring gear 04, and reducing the pressure of the bakelite ring gear...

Embodiment 3

[0031] Bakelite gear 04 has a width of 16mm, the modulus of bakelite gear 04 is 3mm, the number of teeth of bakelite gear 04 is 154, and the number of teeth of drive wheel 06 is 17. Keep the width of bakelite gear 04 unchanged and change the module of related bakelite gear 04 The increase from 2mm to 3mm increases the strength of the bakelite ring gear 04, thereby reducing the wear and tear of the bakelite ring gear 04, reducing the damage rate of the bakelite ring gear 04, and making the overall structure more reasonable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com