Multi-output type coal mining machine traveling mechanism with adjustable height

A traveling mechanism and multi-output technology, which is applied to earth-moving drilling, slitting machinery, propulsion, etc., can solve the problems of frequent shutdown and maintenance, poor mobility of shearers, wear of traveling wheels, etc., to reduce strength and power requirements, improve The effect of poor mobility and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

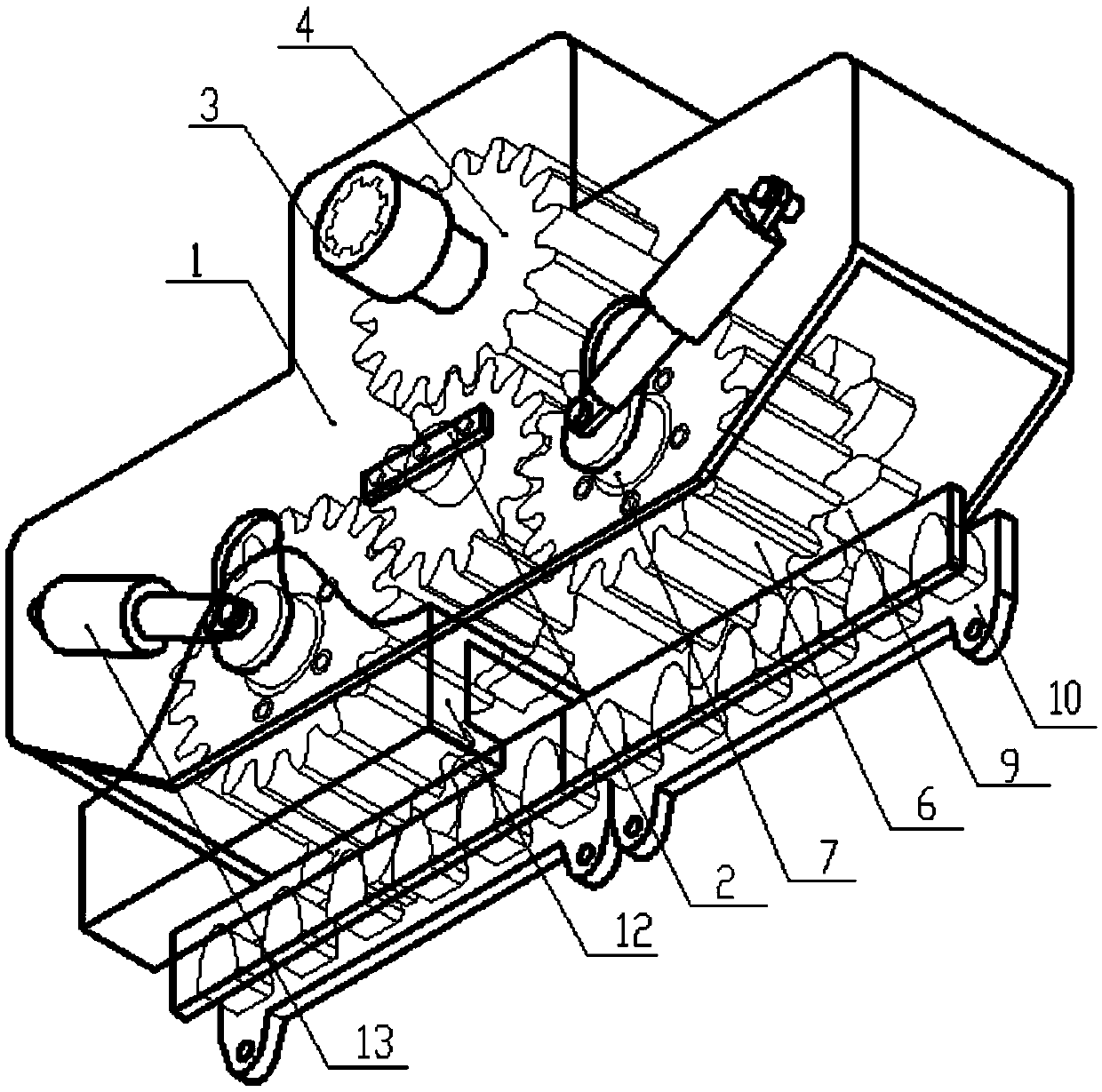

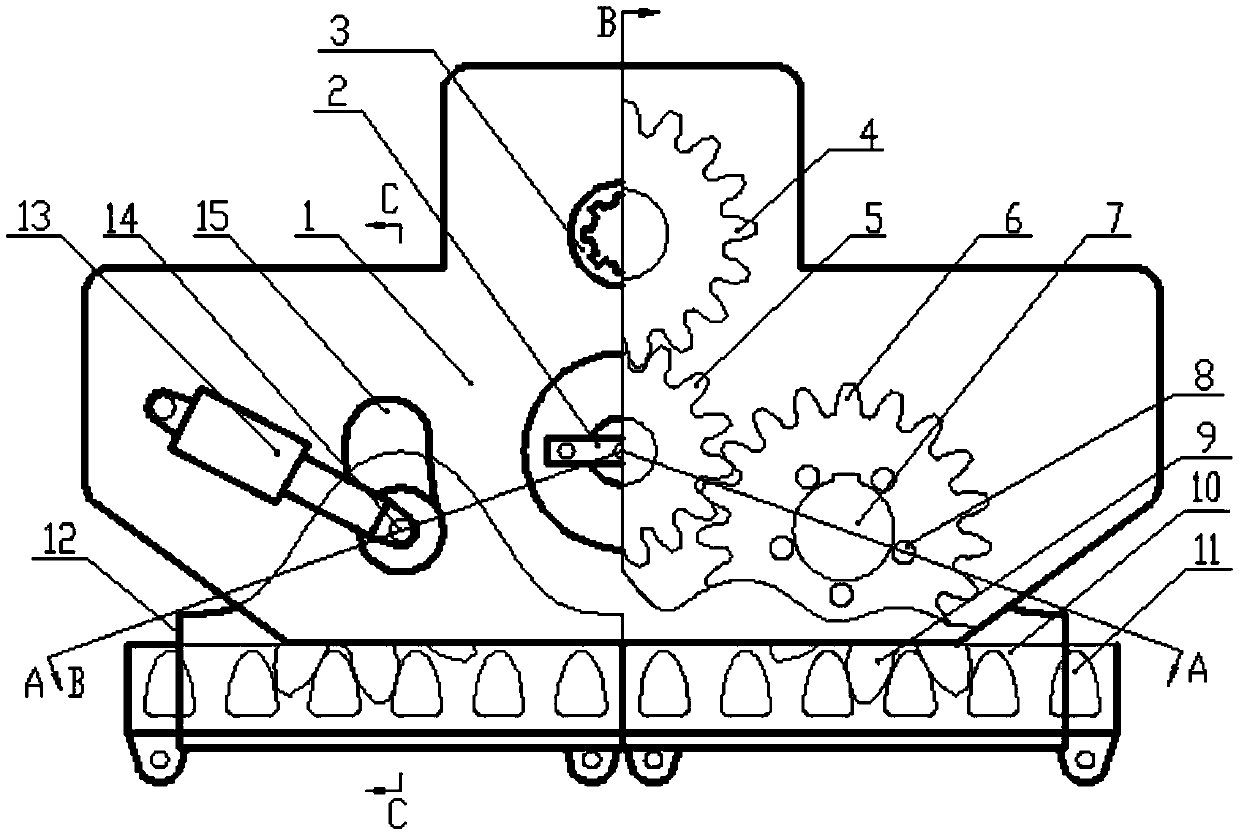

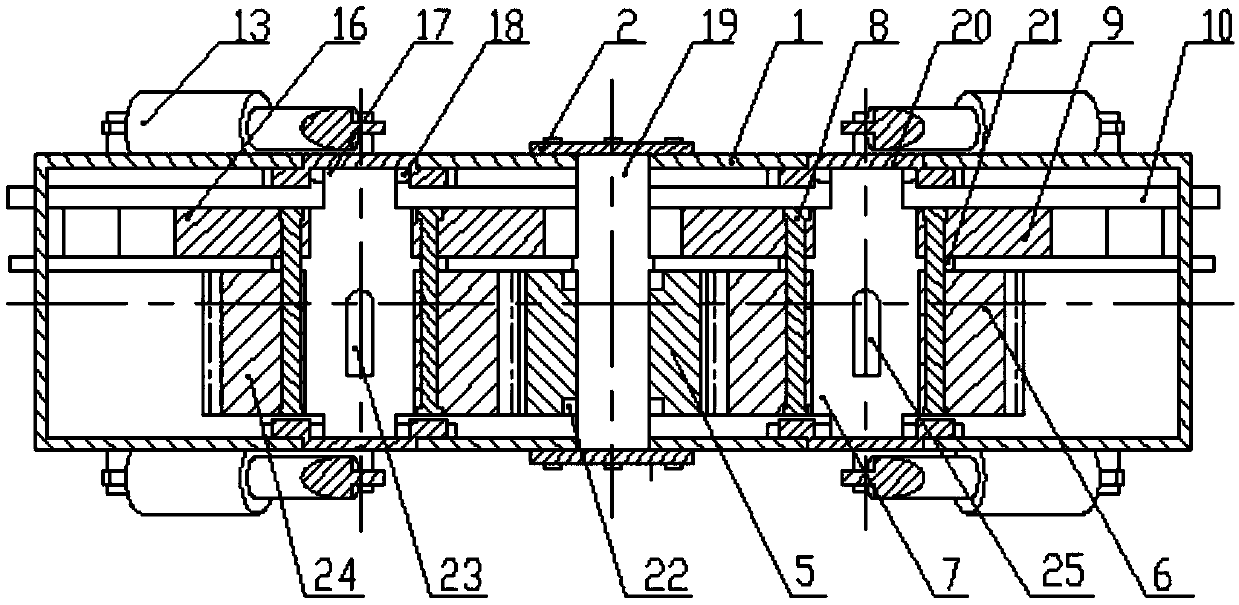

[0036] Such as Figure 1-5 As shown, a height-adjustable multi-output shearer walking mechanism includes a box body 1, a spline shaft 3, a driving gear 4, an idler gear 5, a transmission gear A 24, a transmission gear B 6, and a driving wheel A 16 , walking wheel B 7, pushing jack 13, sliding assembly 15 and pin row 10, a pair of bearings C 26 are installed at the first position of the spline shaft 3 and rotate around the box body 1, and a keyway is opened in the middle of the spline shaft 3 to pass through the ordinary flat key C 27 Connected with the drive gear 4, in order to ensure the safety and efficiency of power transmission, the side of the spline shaft 3 protruding from the box 1 is provided with an inner spline, and the inner spline is assembled and connected with the outer spline of the planetary reduction mechanism as the power input shaft of the traveling mechanism ;

[0037] The idler shaft 19 is fixedly installed on the box body 1, and the idler shaft 19 is fix...

Embodiment 2

[0041] A height-adjustable multi-output shearer walking mechanism, the structure of which is shown in Embodiment 1, the difference is that the outer side of the idler wheel 5 is provided with a shaft end baffle 2, and the two ends of the idler shaft 19 and the shaft end baffle 2 threaded connection, the shaft end baffle 2 and the box body 1 are fixed by bolts, so that the idler shaft 19 is fixed relative to the box body 1 to ensure its circumferential and axial locking.

Embodiment 3

[0043] A height-adjustable multi-output shearer walking mechanism, the structure of which is shown in Embodiment 1, the difference is that the boss 21 is provided with through holes uniformly distributed in the circumferential direction; the outer side of the sliding assembly 20 is provided with guide slides The shoe 12 and the outer side of the sliding assembly 20 are hinged with the lug through hole of the guide shoe 12 , and the sliding assembly 20 is embedded in the chute and is movably connected with the box body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com