Novel organic Rankine cycle power generation system adopting falling film evaporator

A falling-film evaporator, Rankine cycle technology, applied in the direction of evaporator/condenser, steam engine device, machine/engine, etc. To optimize system design, improve power generation efficiency, and increase power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

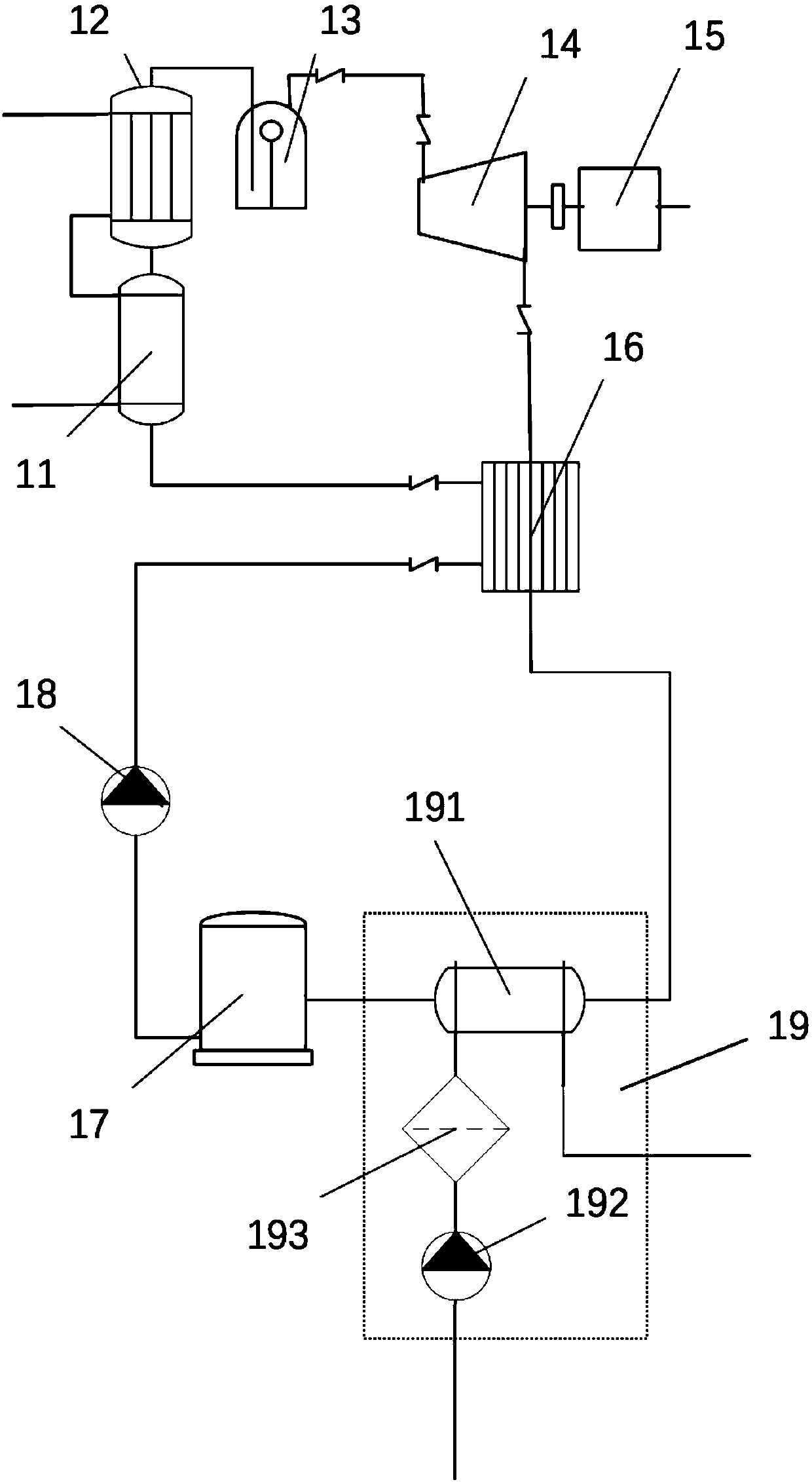

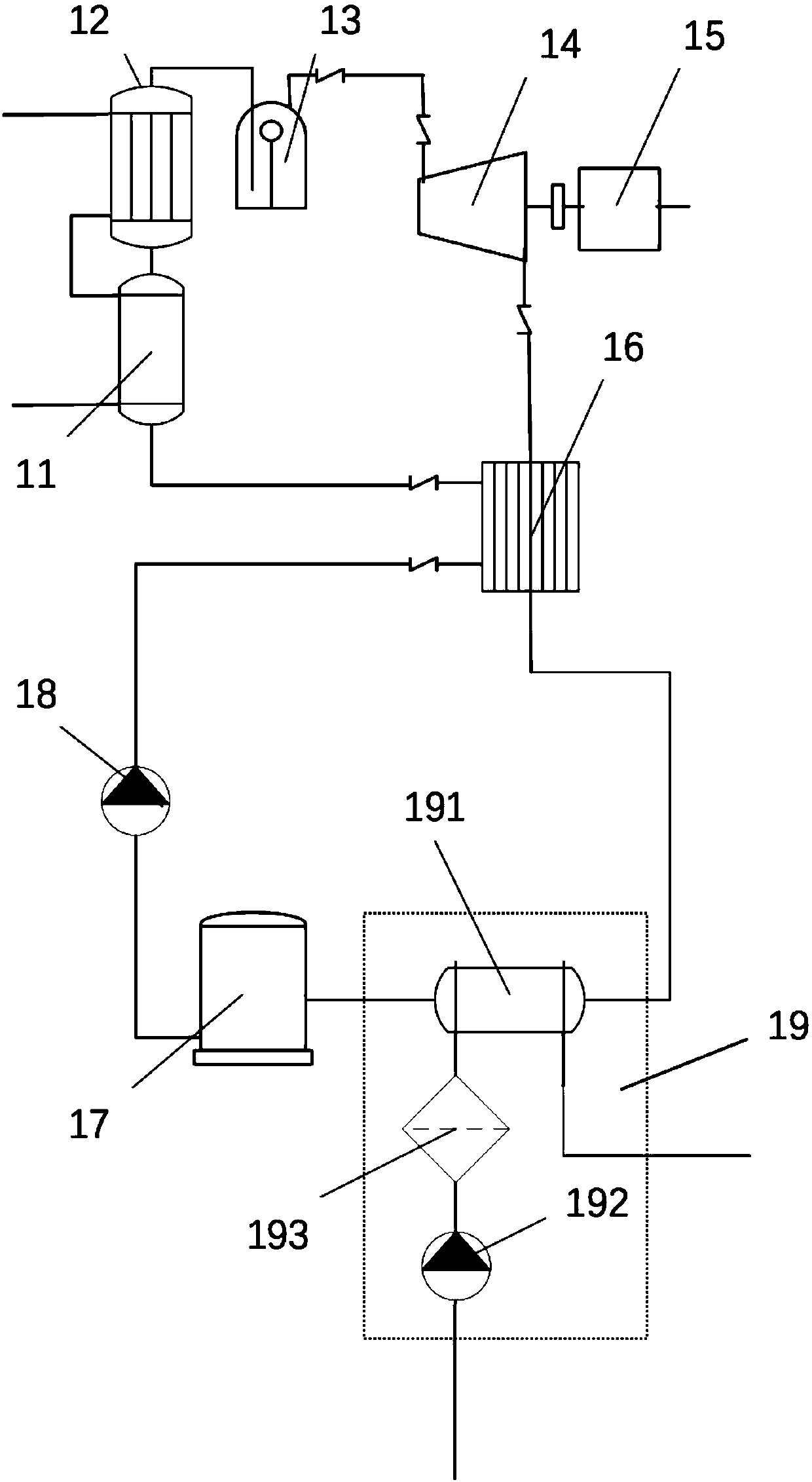

[0021] Such as figure 1 As shown, the embodiment of the present invention provides a novel organic Rankine cycle power generation system using a falling film evaporator, the system includes a preheater 11, a falling film evaporator 12, a gas-liquid separator 13, an expander 14. Generator 15, regenerator 16, liquid reservoir 17, working medium pump 18 and condensation treatment device 19, said condensation treatment device 19 includes condenser 191, water pump 192 and water purification equipment 193, said water pump 192. The water body purification equipment 193 and the condenser 191 are sequentially connected through a circulation pipeline; the falling film evaporator 12 includes a heat source fluid inlet, a heat source fluid outlet, an organic working medium inlet, an organic working medium outlet, a liquid separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com