Permeable cement slurry for steam stimulation to steam flooding reservoir reconstruction

A technology of steam flooding and cement slurry, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of less isolation and transformation of oil and gas layers, and achieve the effect of improving the utilization rate of comprehensive recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 210g fine cement, 90g aluminate cement, 120g high temperature strength stabilizer, 3.6g dispersant SXY, 4.5g fluid loss reducer SZ1-2, 15.9g penetration enhancer MAPT-1 and mix well, weigh 226.8g Add tap water to the corrugated mixing tank, add the uniformly mixed dry powder into the corrugated tank, stir at high speed for 45s, stir at low speed for 15s, and then thicken at 80°C for 20 minutes to prepare a steam huff and puff steam huff and puff to steam flooding layer transformation. Grout.

Embodiment 2

[0024] 210g fine cement + 90g aluminate cement + 120g high-temperature strength stabilizer + 3.6gSXY + 14.5gSZ1-2 + 15.9gMAPT-1, the water-solid ratio is 0.54, and the high-temperature strength stabilizer is silica sand with an average particle size of 48μm (300 mesh) .

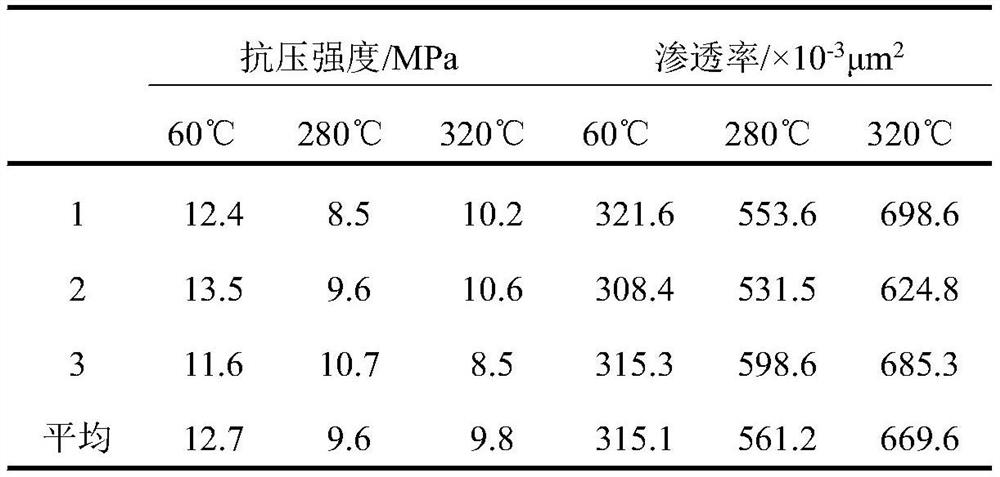

[0025] The cement slurry was prepared according to the above formula and injection molded, and cured in water baths at 60°C, 280°C, and 320°C for 72 hours, and the compressive strength and oil phase permeability of cement stones reaching the curing age were measured. The test method for compressive strength of cement stone is in accordance with GB / T 19139-2003 "Oil Well Cement Experimental Method", and the test method for cement stone permeability is in accordance with SY / T5336-1996 "Routine Analysis Method for Rock Core". The test results are shown in Table 1.

[0026] Table 1 cement stone test results

[0027]

[0028] It can be seen from the data in the above table that after cu...

Embodiment 3

[0031] 210g fine cement + 90g aluminate cement + 120g high-temperature strength stabilizer + 3.6gSXY + 14.5gSZ1-2 + 15.9gMAPT-1, the water-solid ratio is 0.54, and the high-temperature strength stabilizer is silica sand with an average particle size of 48μm (300 mesh) .

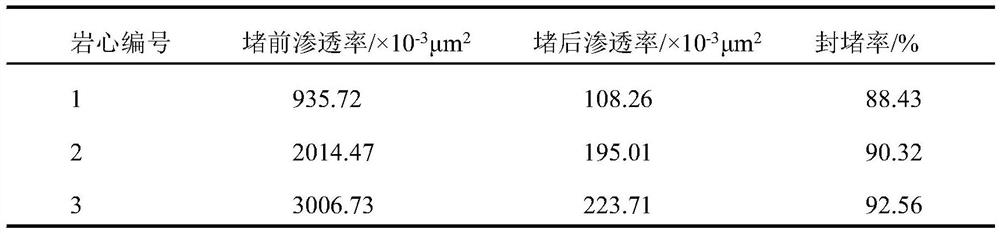

[0032] The cement slurry was prepared according to the above formula, and the permeable cement slurry system was injected into the core with a flow rate of 1mL / min. After that, the core injected with cement slurry was taken out, placed in a constant temperature water bath system at 80°C for 1 day, and then transferred to 280°C under high temperature and high pressure. After 2 days of curing in the kettle, take it out and put it in the core holder, and conduct the plugging effect experiment of cement stone. The test results are shown in Table 2.

[0033] Table 2 Permeable cement plugging data of single core

[0034]

[0035] It can be seen from the above table that after the permeab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com