Underground in-situ gasification and pyrolysis integrated co-mining method for oil-rich coal

An in-situ pyrolysis and pyrolysis technology, applied in coal gasification, underground mining, mining fluids, etc., can solve the problems of single utilization mode and low resource utilization rate, avoid thermal energy waste, reduce thermal energy loss, and improve comprehensive utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

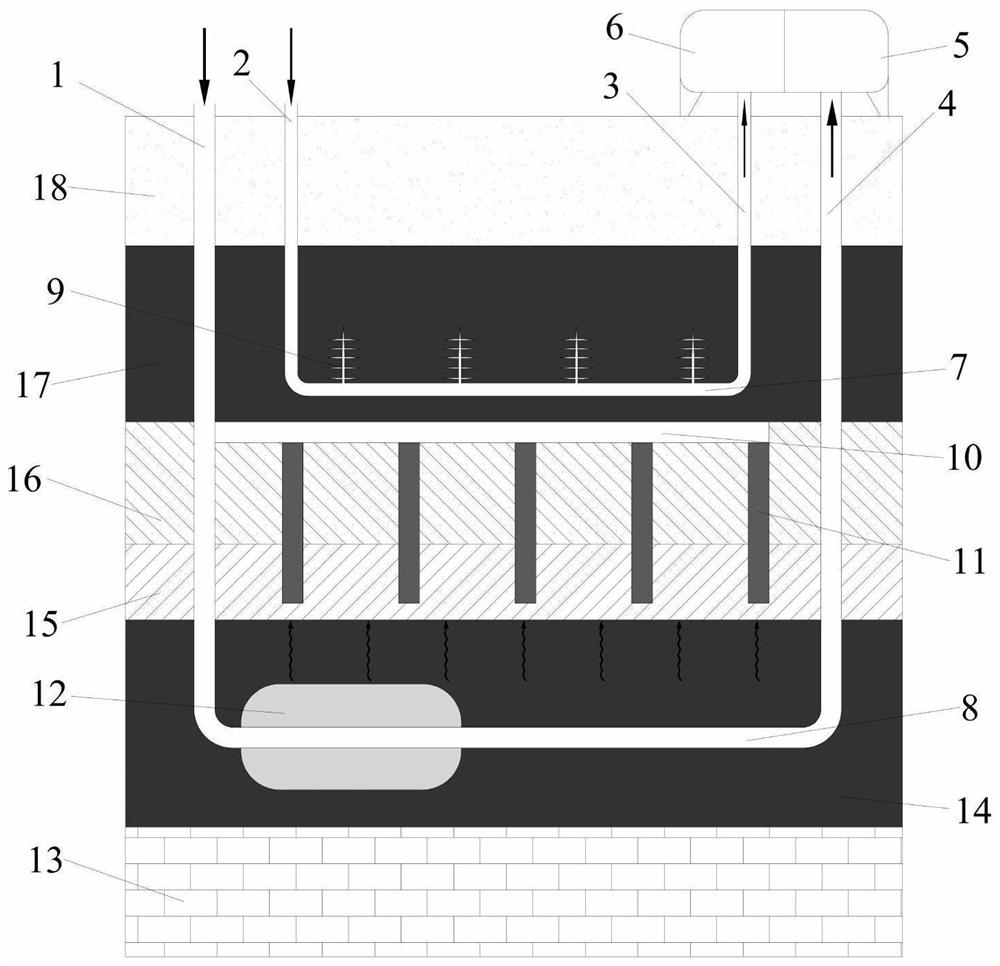

[0033] figure 1 , The present embodiment includes the following steps:

[0034] A step, in the vertical direction from the lower face of the coal seam 14 rich excavation gasification and gasification injection channel 1 output channel 4, and then communication between the gasification excavation injection channel 1 output gasification in the lower seam 14 gasification horizontal channels 4 8 wells; seam top and bottom of the lower layer 14 are respectively provided under the underlying strata 13 and the lower cladding layer 15 has a lower seam on the seam;

[0035] Step two, the excavation 17 in the upper pyrolysis oil rich coal seam oriented along the vertical direction from the injection channel 2 and channel 3 output pyrolysis, the pyrolysis and communication excavation in the upper seam 172 and injection passage pyrolysis pyrolysis output channel 3 of 7 horizontal wells; seam top and bottom of the upper layer 17 are respectively provided with an overburden and underburden 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com