A kind of water base completion fluid and its preparation and application

A completion fluid, water-based technology, used in wellbore/well components, chemical instruments and methods, sealing/packaging, etc. Development and other issues, to achieve the effect of high viscosity reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The inorganic salt of 90 mass parts and organic salt (sodium chloride, potassium chloride, calcium chloride, calcium bromide, sodium formate, cesium formate and potassium formate, mass ratio is 6:1:5:1:2:11: 19) Add 55 parts by mass of simulated seawater (the salinity is 34.61g / L). At this time, the salinity of the water is 3468g / L. Stir until it is completely dissolved. Add 0.5 parts by mass of compound I (R1 in compound I is phenyl, n is 50 to 70), 0.1 parts by mass of cationic surfactant (that is, a total of 0.6 parts of anti-reverse emulsifier); stir well and add 1.5 parts by mass Compound II (R2 and R3 in compound II are n-butyl, n is 65 to 85), 0.5 parts by mass of 20 to 30 ionicity cationic polyacrylamide (that is, a total of 2 parts of clay inhibitor), stir well and add 0.5 parts by mass of corrosion inhibitor, fully stirred and circulated, the stirring time ≥ 50 minutes, and the temperature ≥ 5°C, to obtain a water-based completion fluid for heavy oil reservoir...

Embodiment 2 to 6

[0072] The preparation method is the same as that of Example 1, and the difference between Examples 2 to 6 and Example 1 is that the amount of each material is different, as shown in Table 5 below (parts by mass). The ratio of each component in the anti-reverse emulsifier and clay inhibitor is the same as that in Example 1.

[0073] table 5:

[0074]

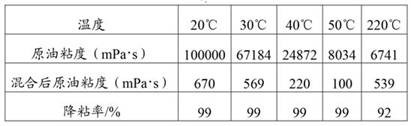

[0075] The performance evaluations of Examples 2 to 6 are the same as in Example 1, and the performance evaluation results are shown in Table 6.

[0076] Table 6:

[0077]

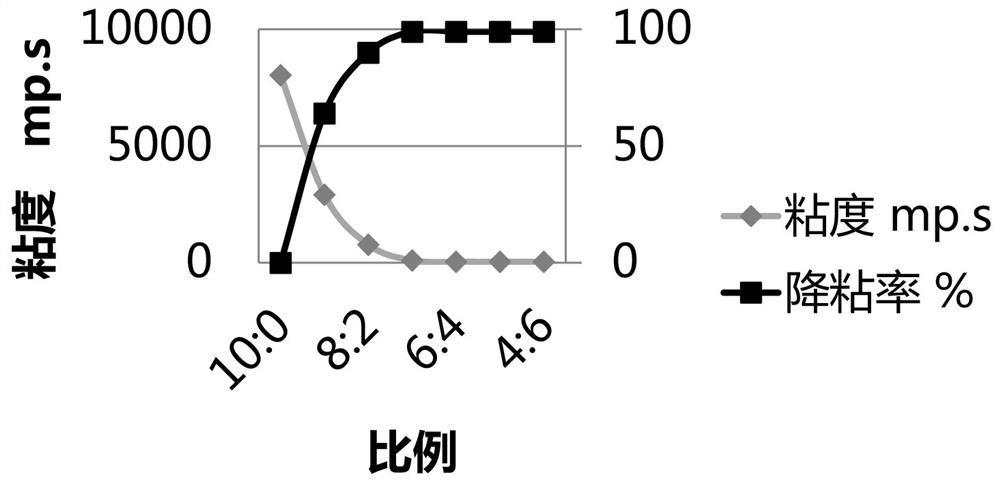

[0078] The test temperature of the viscosity reduction rate is 220° C., and when the temperature is lower than 220° C., the viscosity reduction rate of the water-based completion fluids provided in Examples 2 to 6 will be better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com