Pressure automatic leakage stopping type gate valve

A pressure and automatic technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve problems such as waste of labor costs and time, pressure leakage of gate valves, and cumbersome disassembly by staff, so as to improve work efficiency and make it difficult to disassemble and maintain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

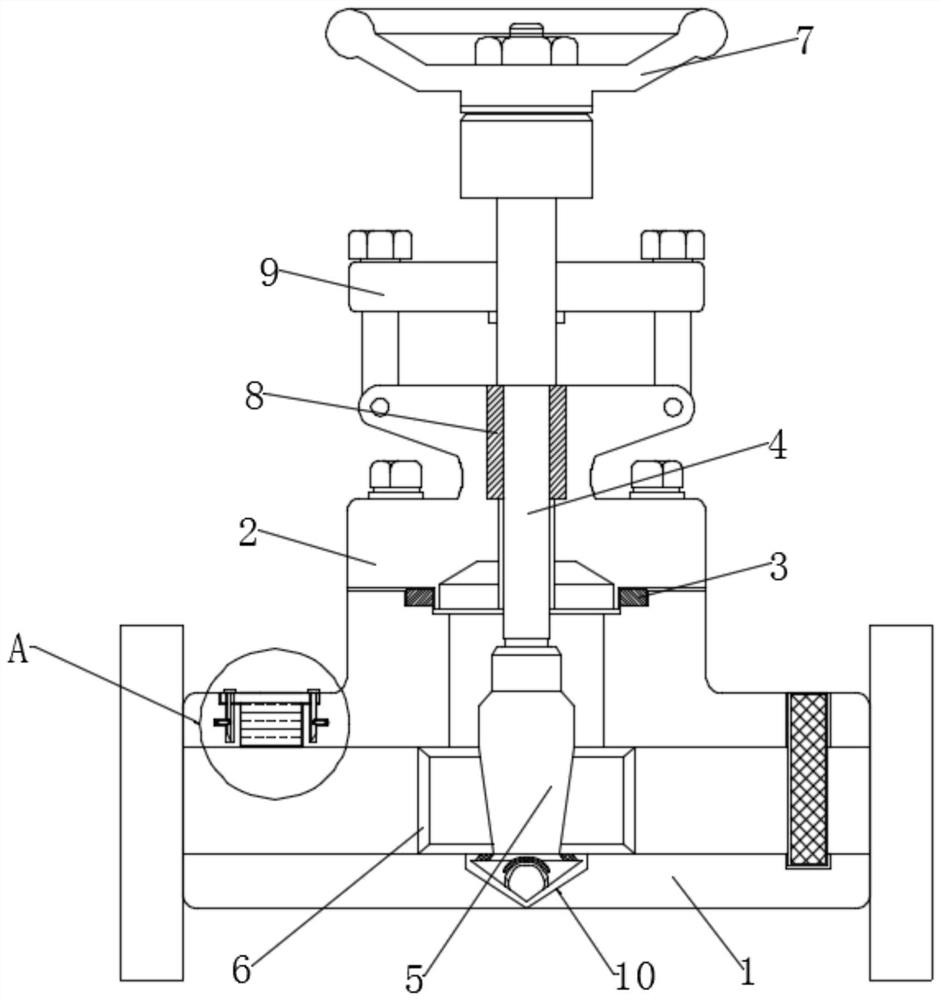

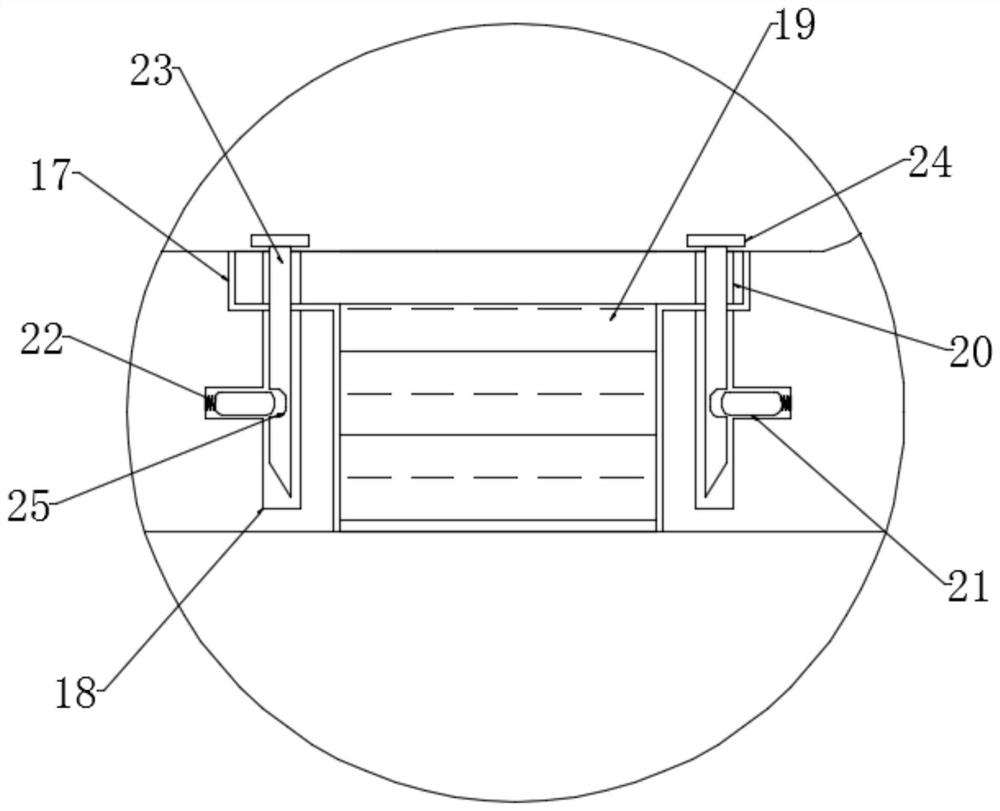

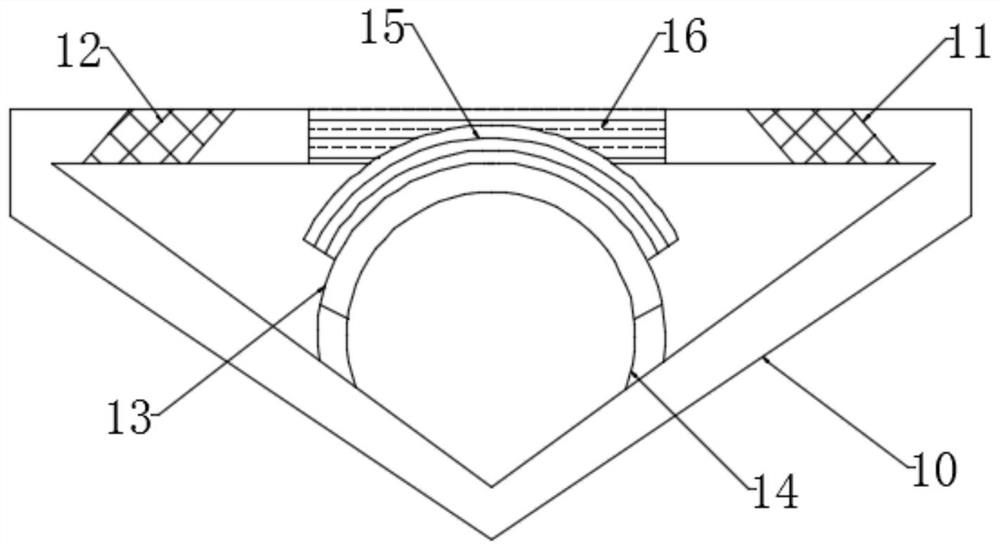

[0042] see Figure 1-5 , a pressure automatic leak-proof gate valve, comprising a valve body 1, the outer end of the valve body 1 is provided with a bonnet 2, the contact between the valve body 1 and the bonnet 2 is glued with a graphite gasket 3, the bonnet 2 and the valve body 1 Via bolts to form a movable connection, the internal thread of the valve body 1 is connected to the valve stem 4, the valve stem 4 runs through the valve cover 2, the bottom end of the valve stem 4 is connected to the valve plate 5 in rotation, and the inside of the valve body 1 is close to the valve plate 5 There is a valve seat 6 on one side, a hand wheel 7 is fixed on the top of the valve stem 4, a packing gland 8 is arranged on the outside of the valve stem 4, and the packing gland 8 is located inside the valve cover 2, and the top of the valve cover 2 is provided with a packing pressure plate 9. The packing plate 9 and the valve cover 2 are flexibly connected by bolts. The inner bottom of the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com