Patents

Literature

64results about How to "Prevent pressure leaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

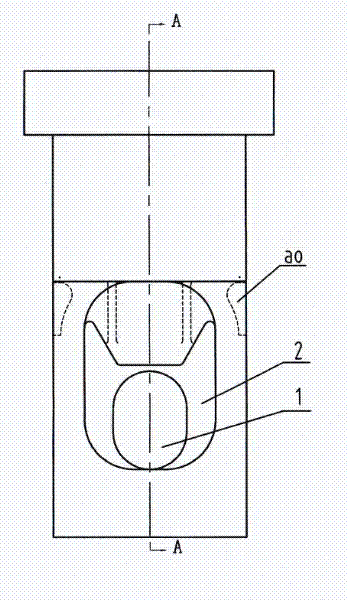

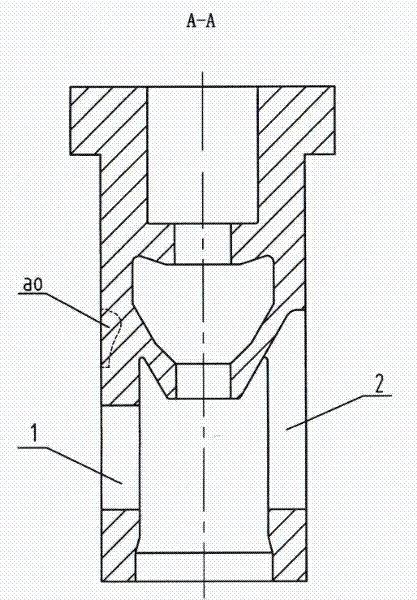

Casting die for valve shell casting of marine diesel engine and casting process of valve shell

ActiveCN102463326AReasonable structureAdvanced layoutFoundry mouldsFoundry coresExhaust valveDiesel engine

The invention discloses a casting die for a valve shell casting of a marine diesel engine and a casting process of the valve shell. The casting die is mainly characterized in that a contoured chill is additionally arranged at the outer end face of the flange cavity of the valve shell, a combined sand core is adopted, a chrome sand layer is distributed at the thick part of the casting wall of the sand core, and pouring gates and dead heads are reasonably arranged. The casting process is mainly characterized by comprising compounding, smelting, treatment before assembly of the casting die and die assembling by matching core, pouring and cleaning. The casting die for the valve shell casting of the marine diesel engine and the casting process of the valve shell has the advantages of reasonable structure of the casting die, simplicity and easiness to control in the casting process, uniformness in cooling of the casting and good feeding effect, effectively overcomes the leakage of the finished valve shell, and provides support for localization of all valve shell castings.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

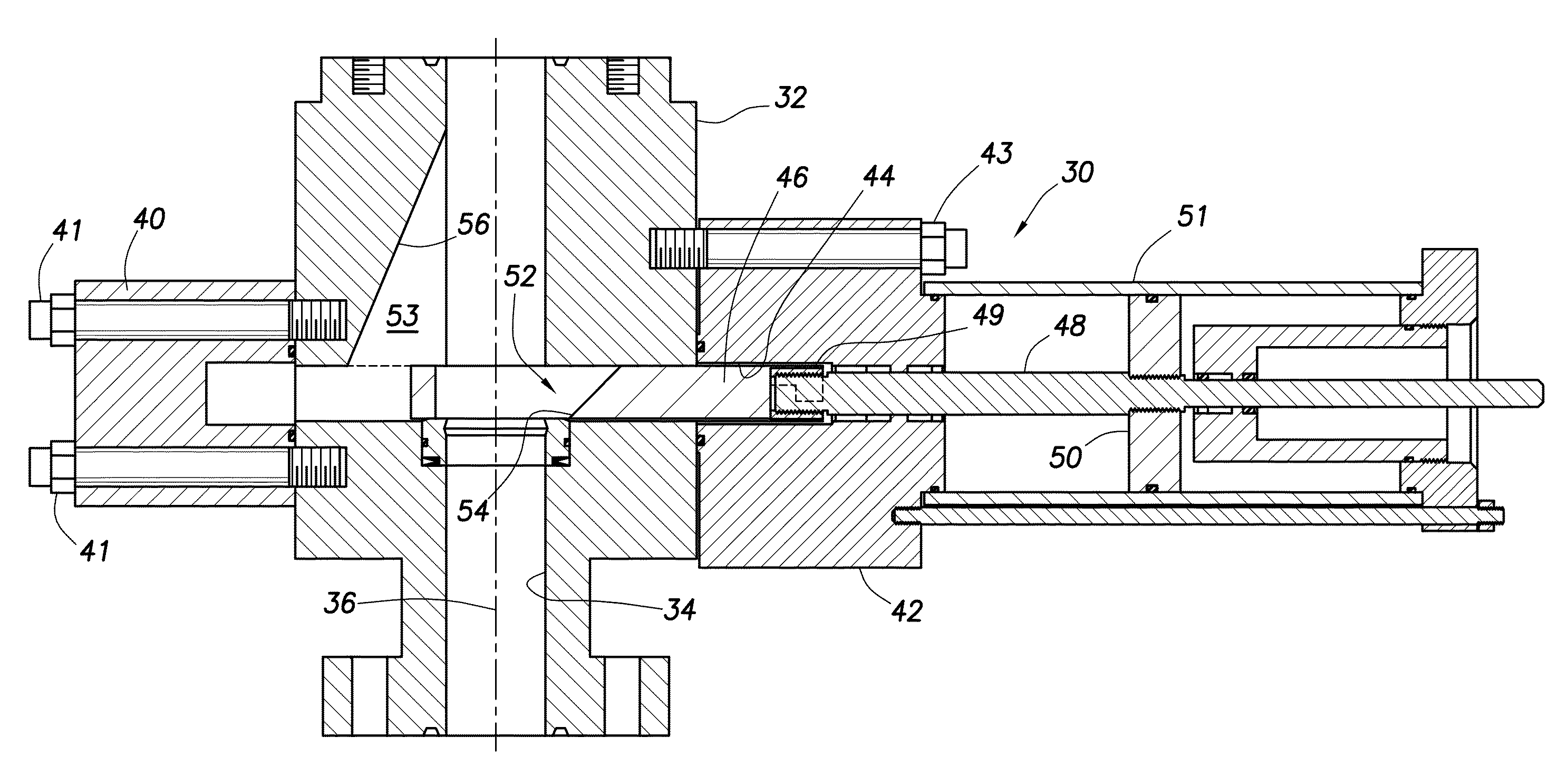

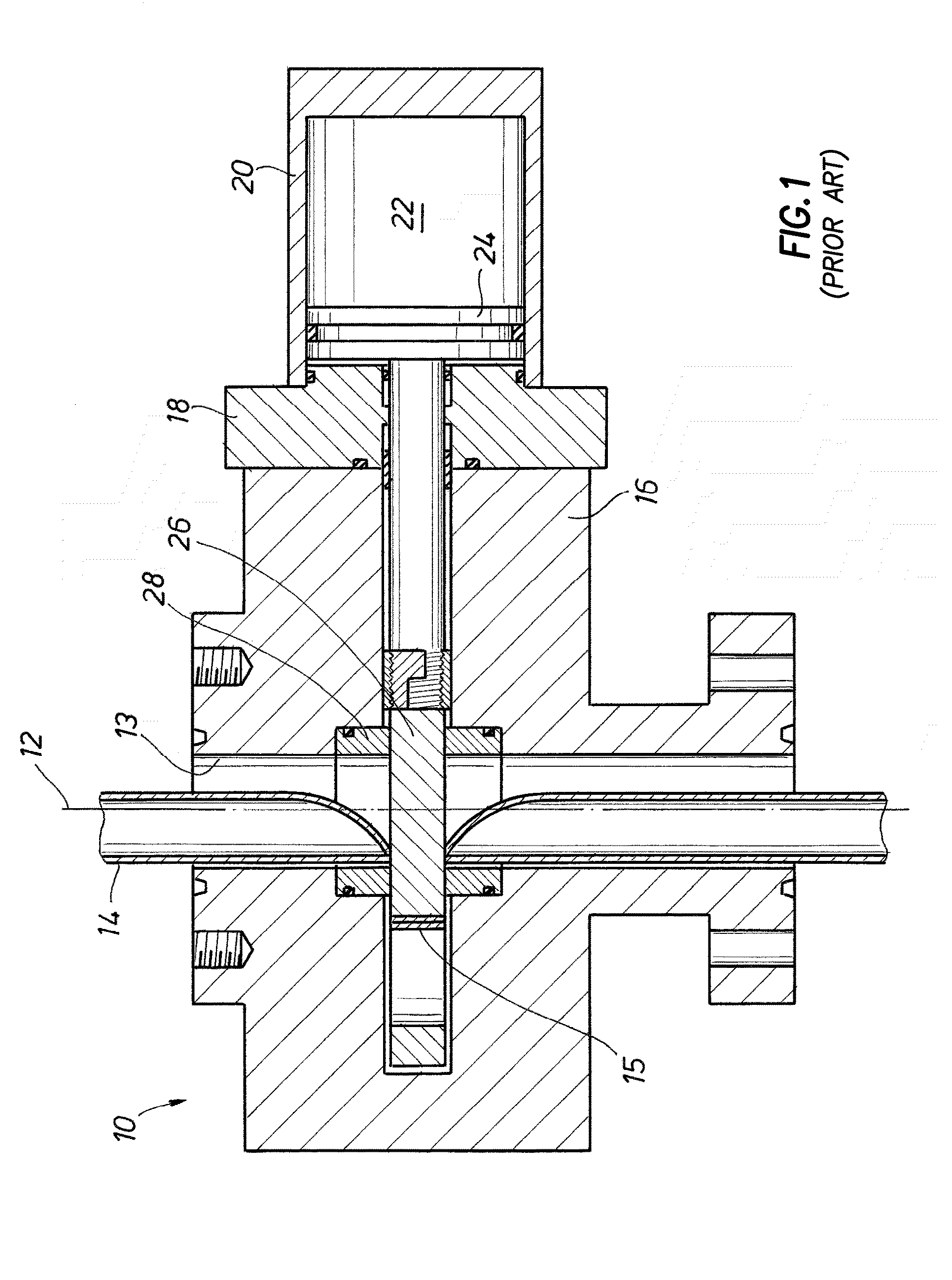

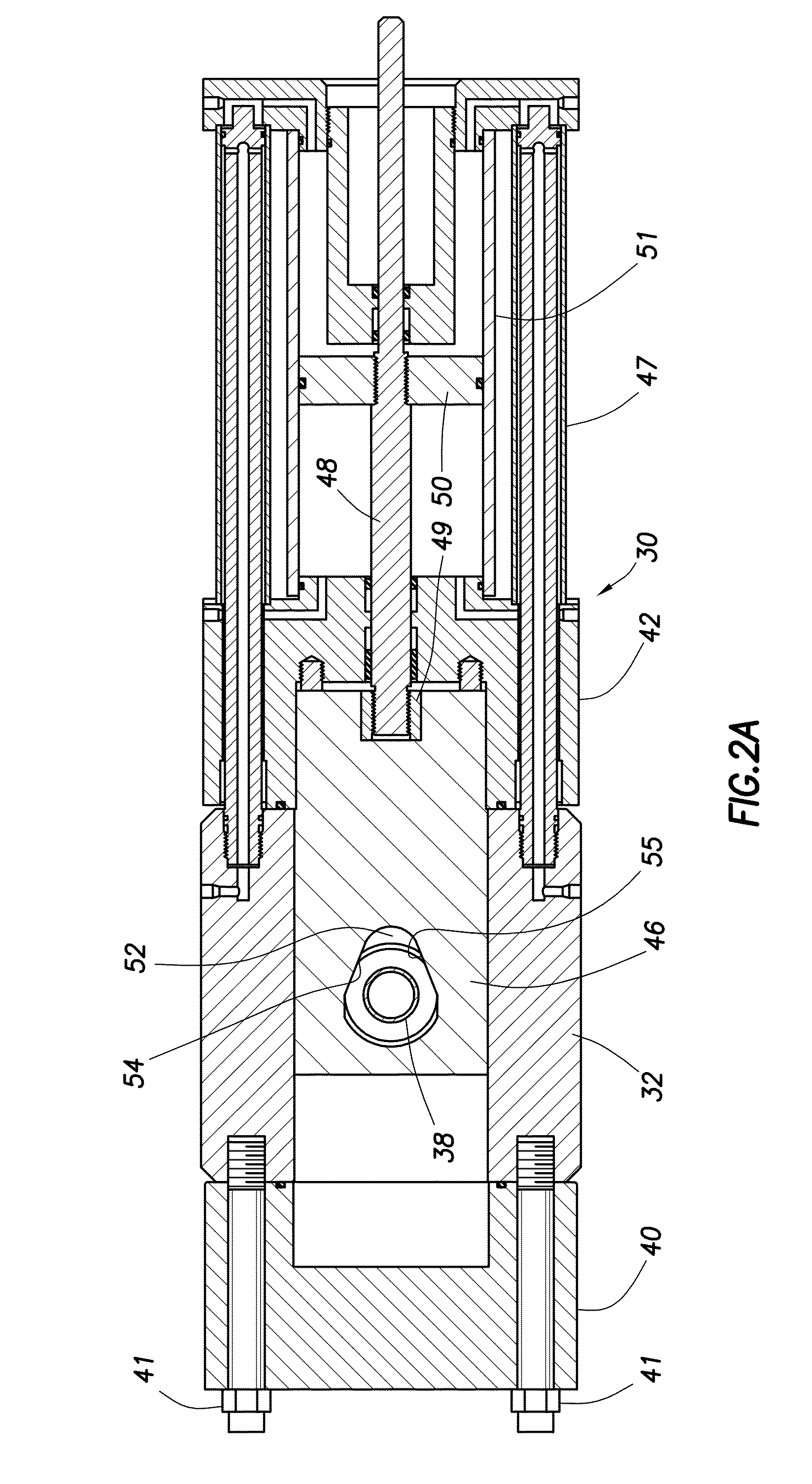

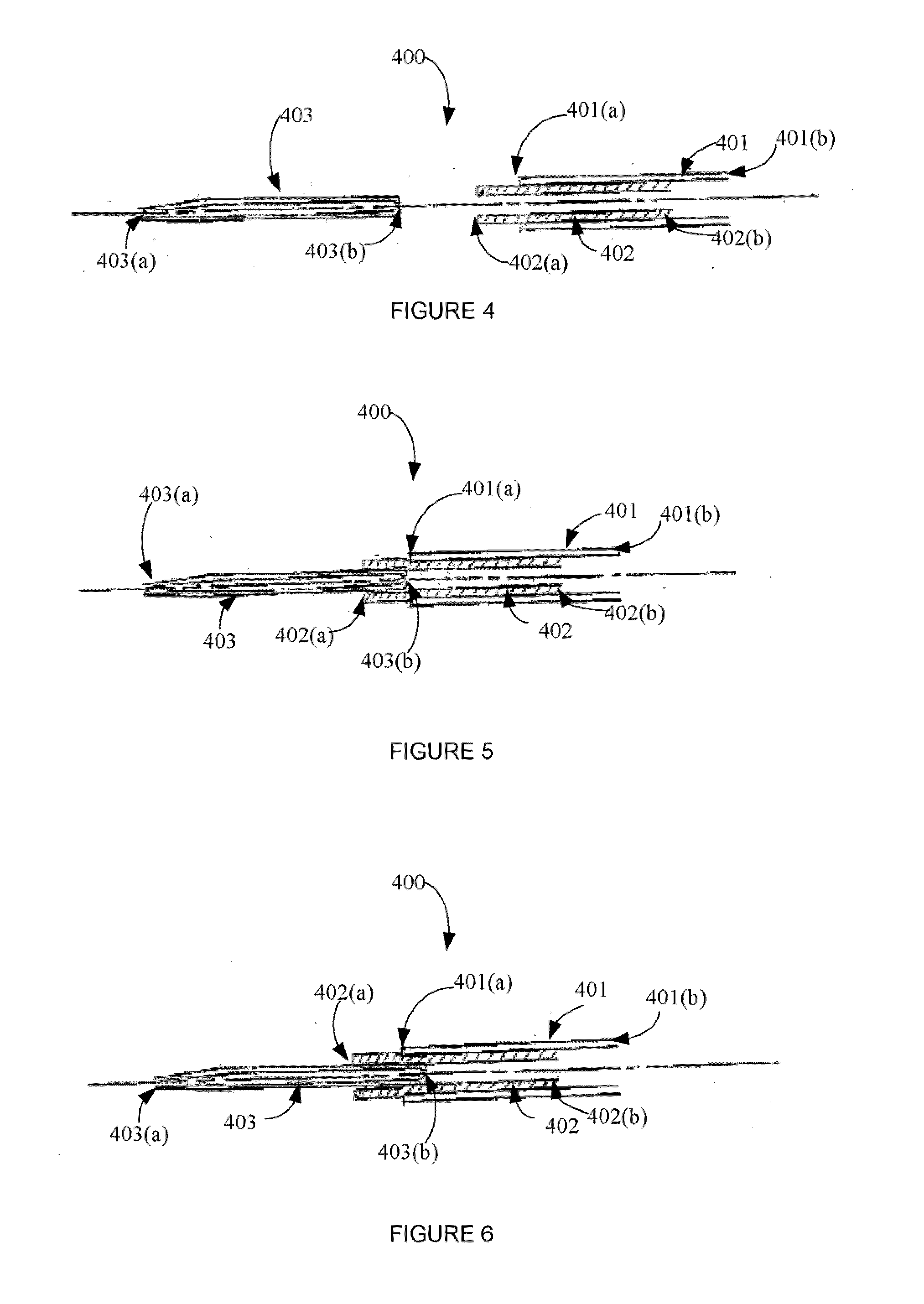

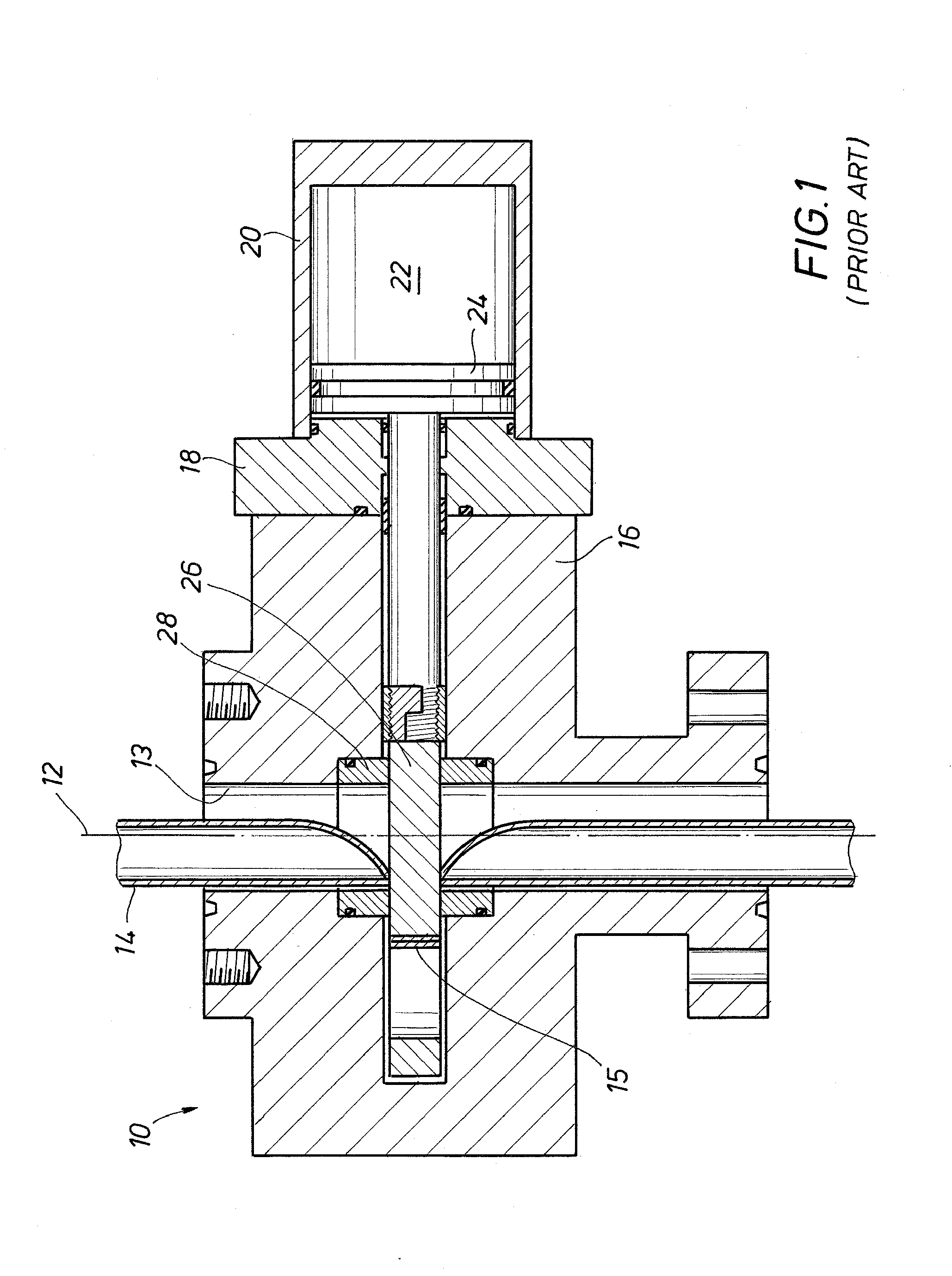

Shear seal blowout preventer

ActiveUS8567490B2Prevent pressure leaksMinimize cutting forceDrilling rodsFluid removalCoiled tubingEngineering

A shear / seal ram provides a knife edge at the shearing edge and the knife edge is inclined to minimize the cutting force required and to leave a clean cut edge. The knife edge is presented in an opening of the ram, thus the opening is positioned at the axis of the BOP, and consequently the coiled tubing, before the coiled tubing is run through the BOP. A biasing means, such as for example a Bellville spring, forces a sealing sleeve against the underside of the ram to prevent leakage of pressure from below the BOP. Similarly, a plurality of biasing means, referred to herein as “skates”, forces the ram down against the sealing sleeve to seal pressure from above the BOP.

Owner:NAT OILWELL VARCO LP

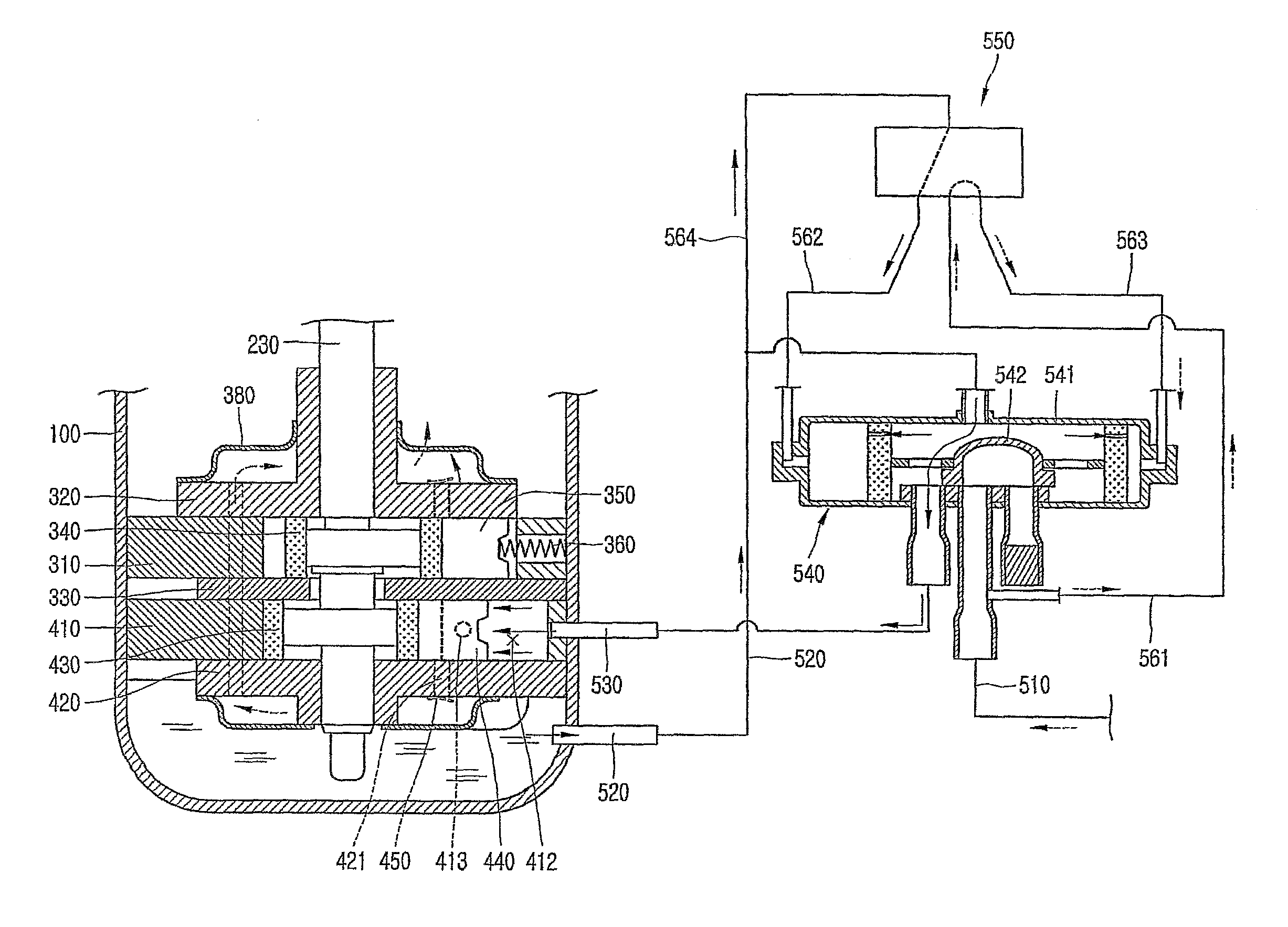

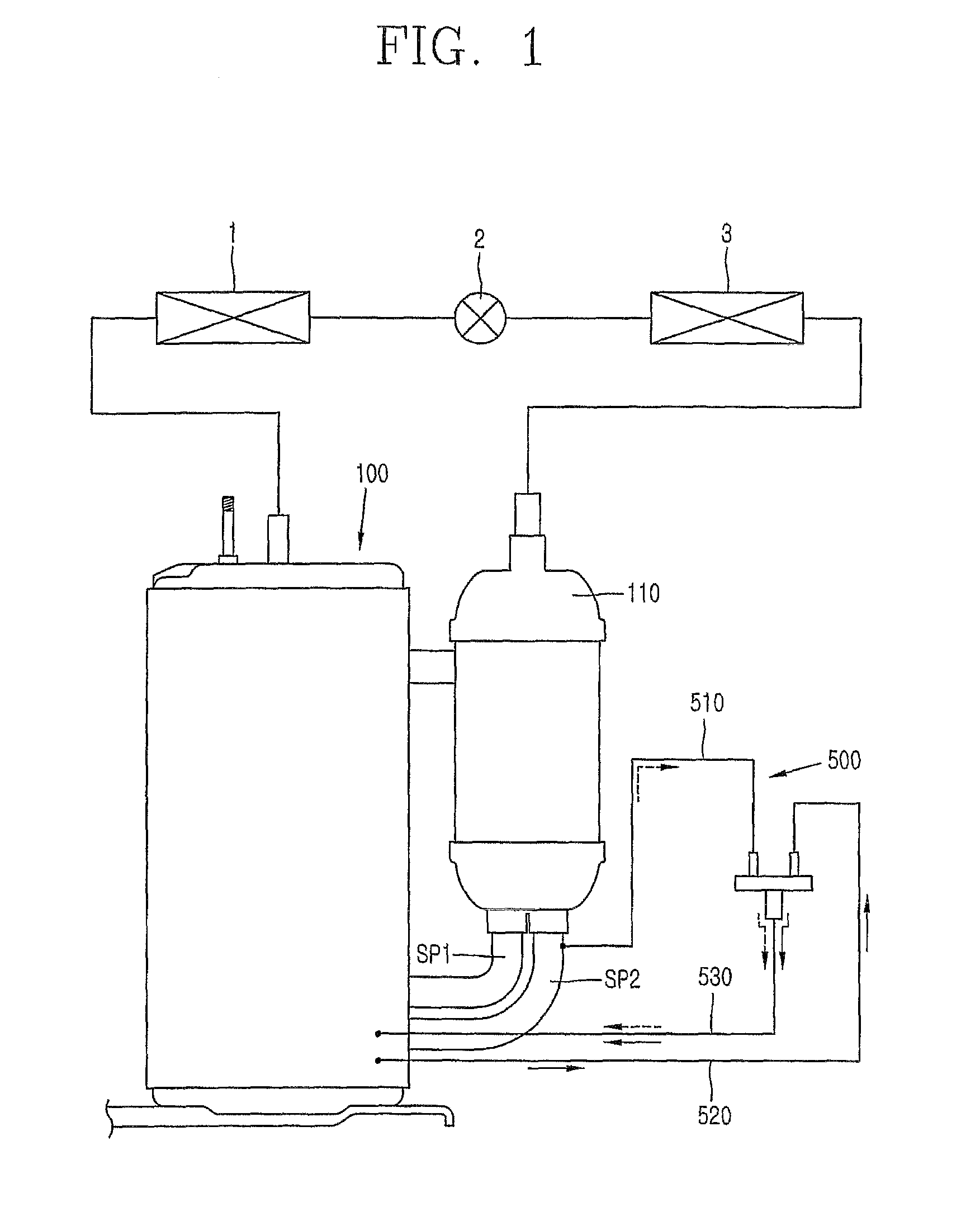

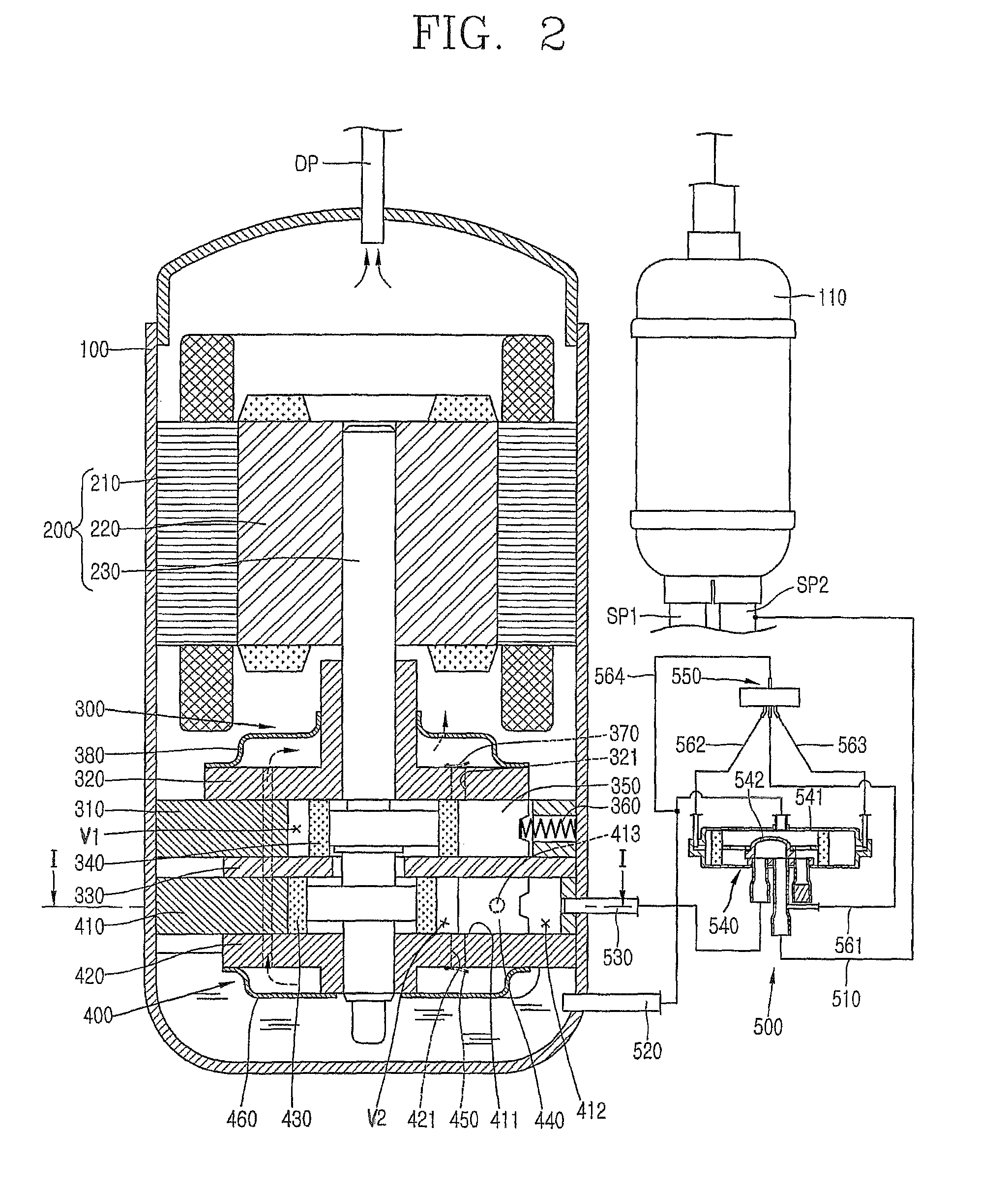

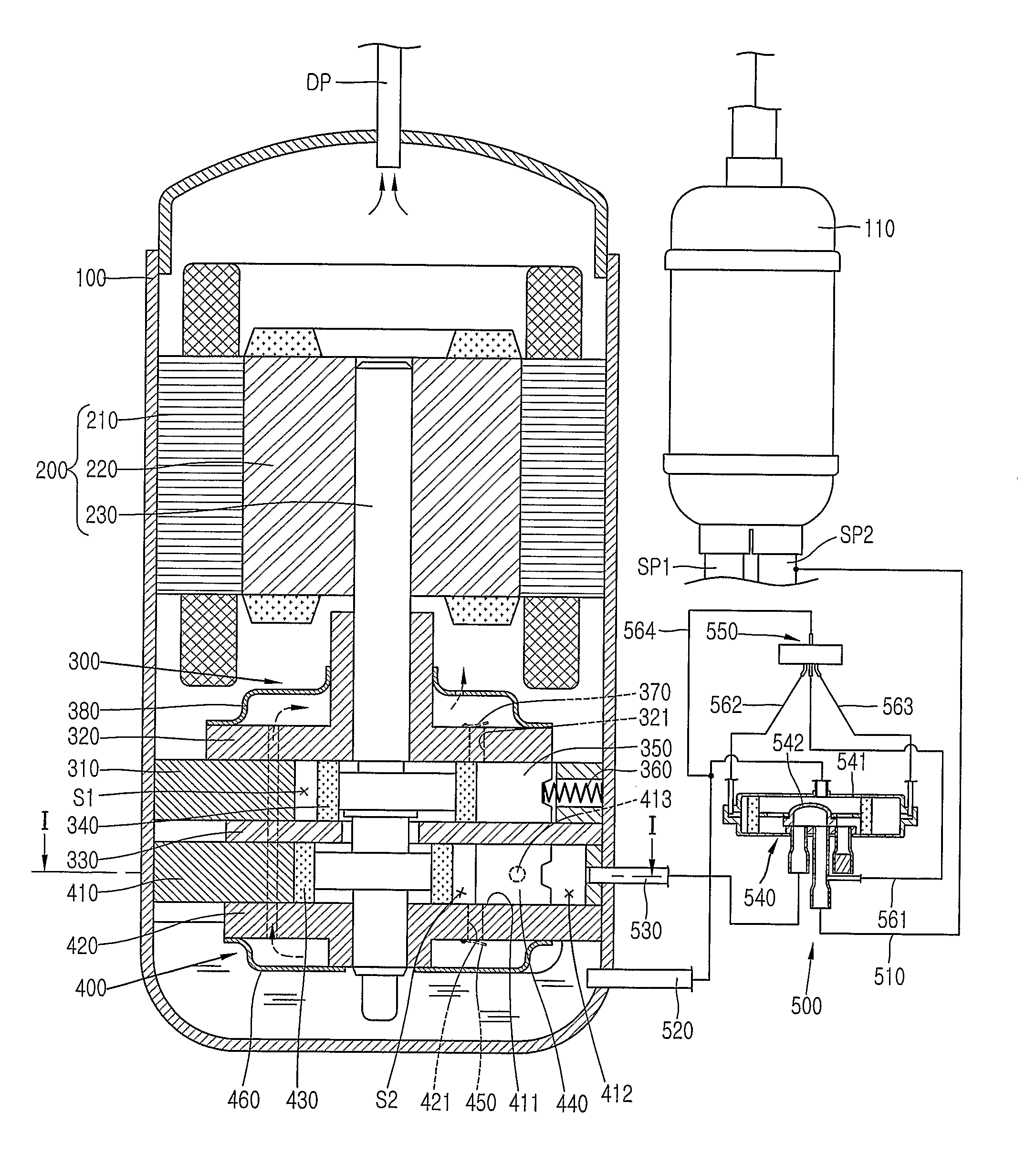

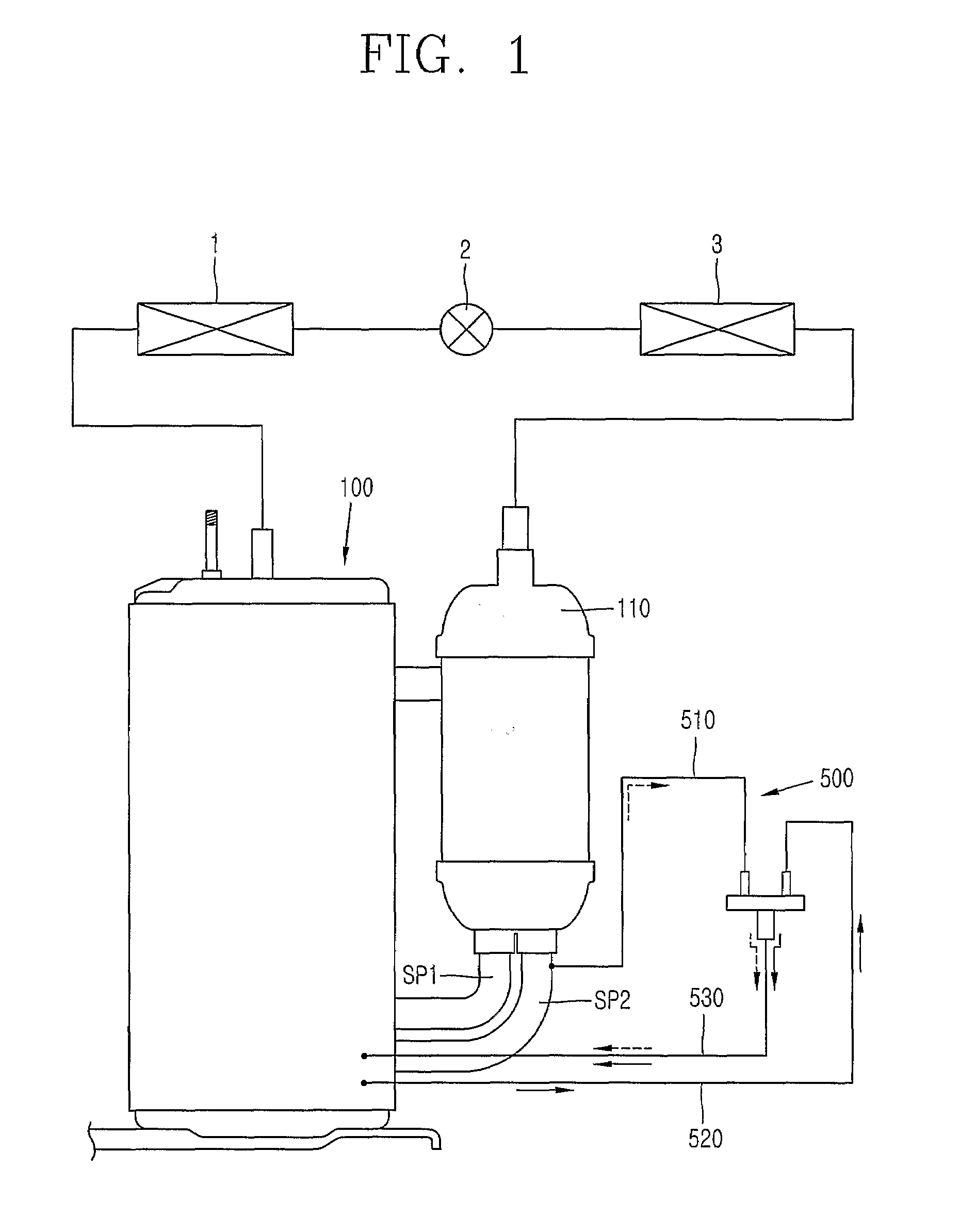

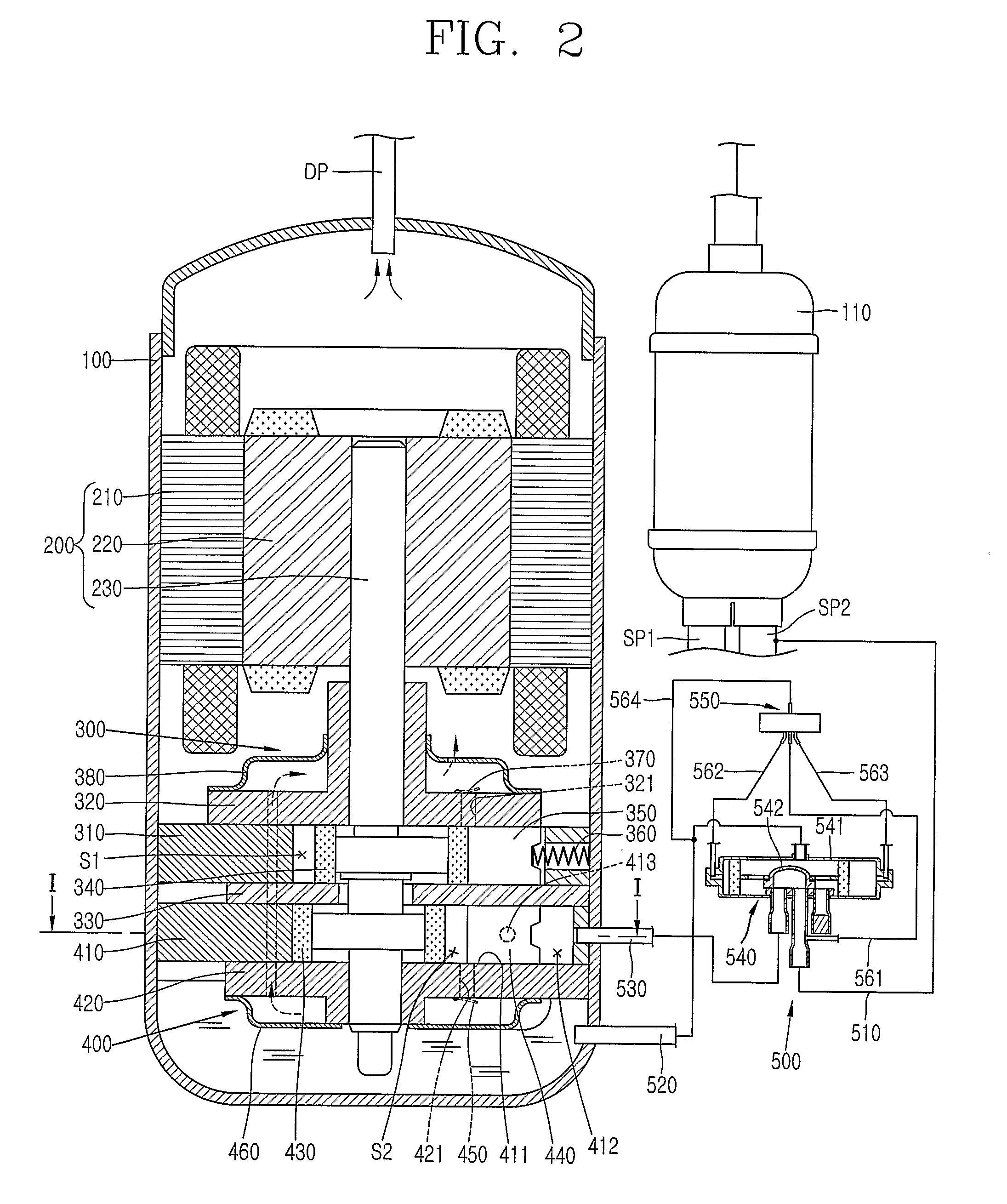

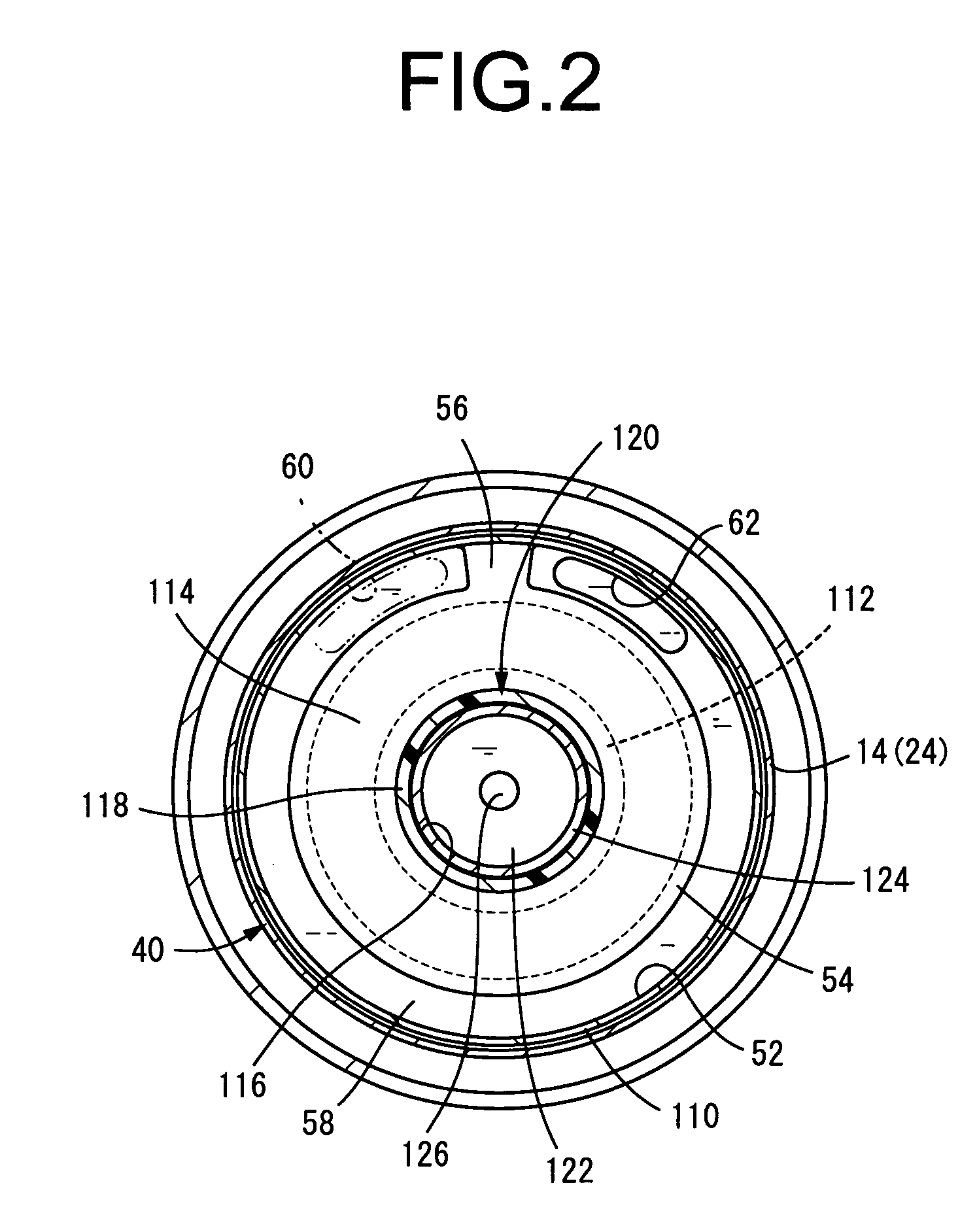

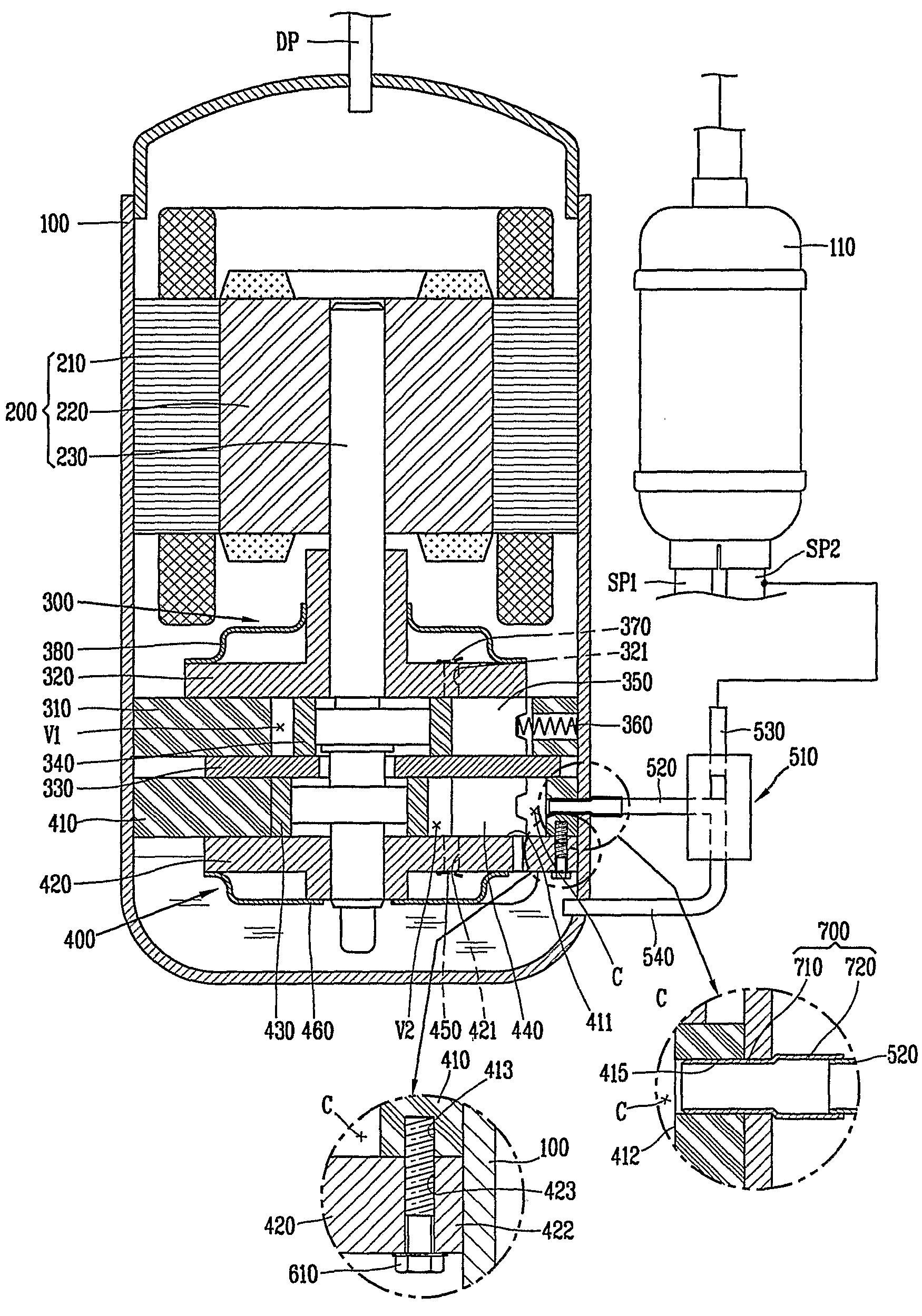

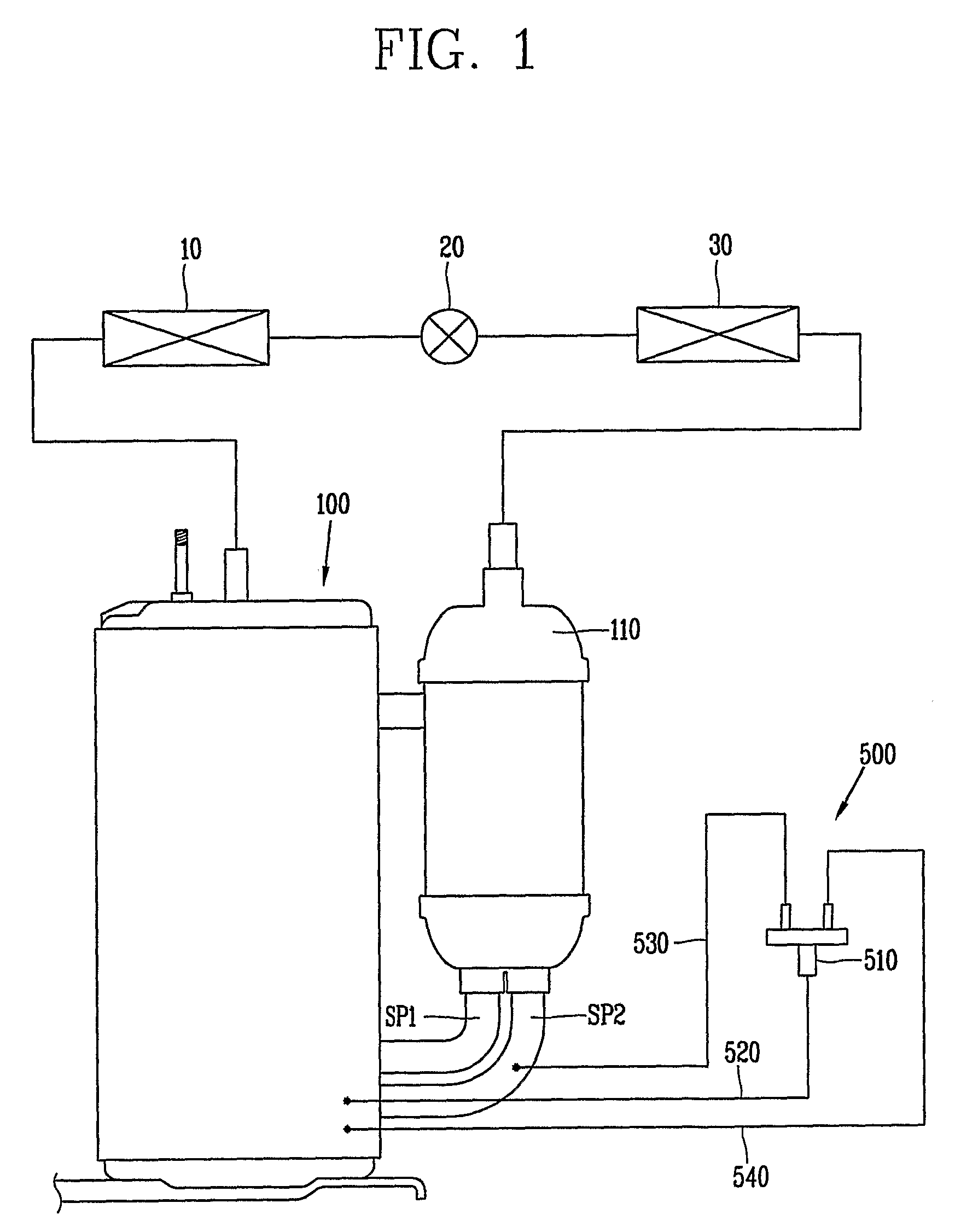

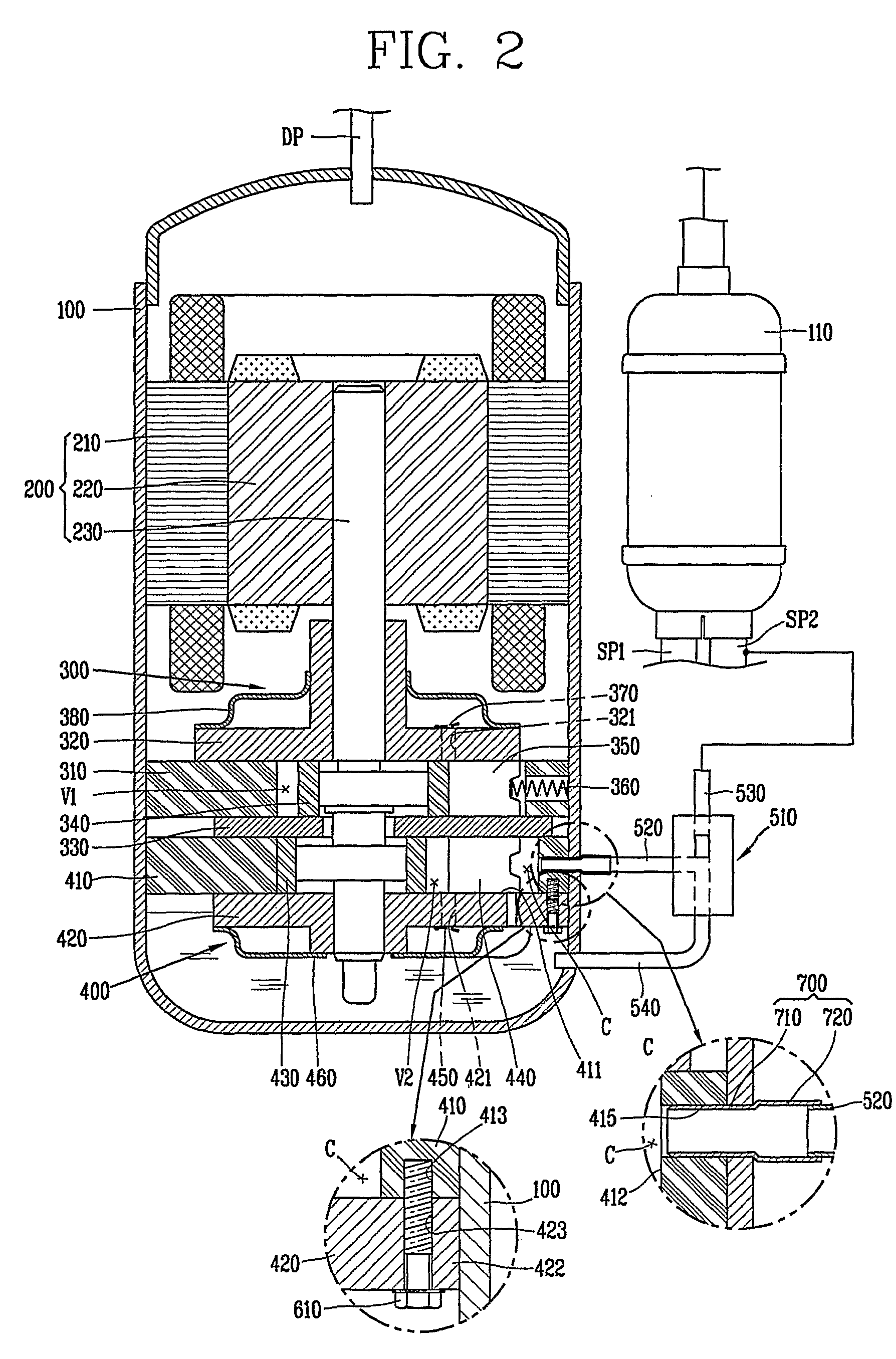

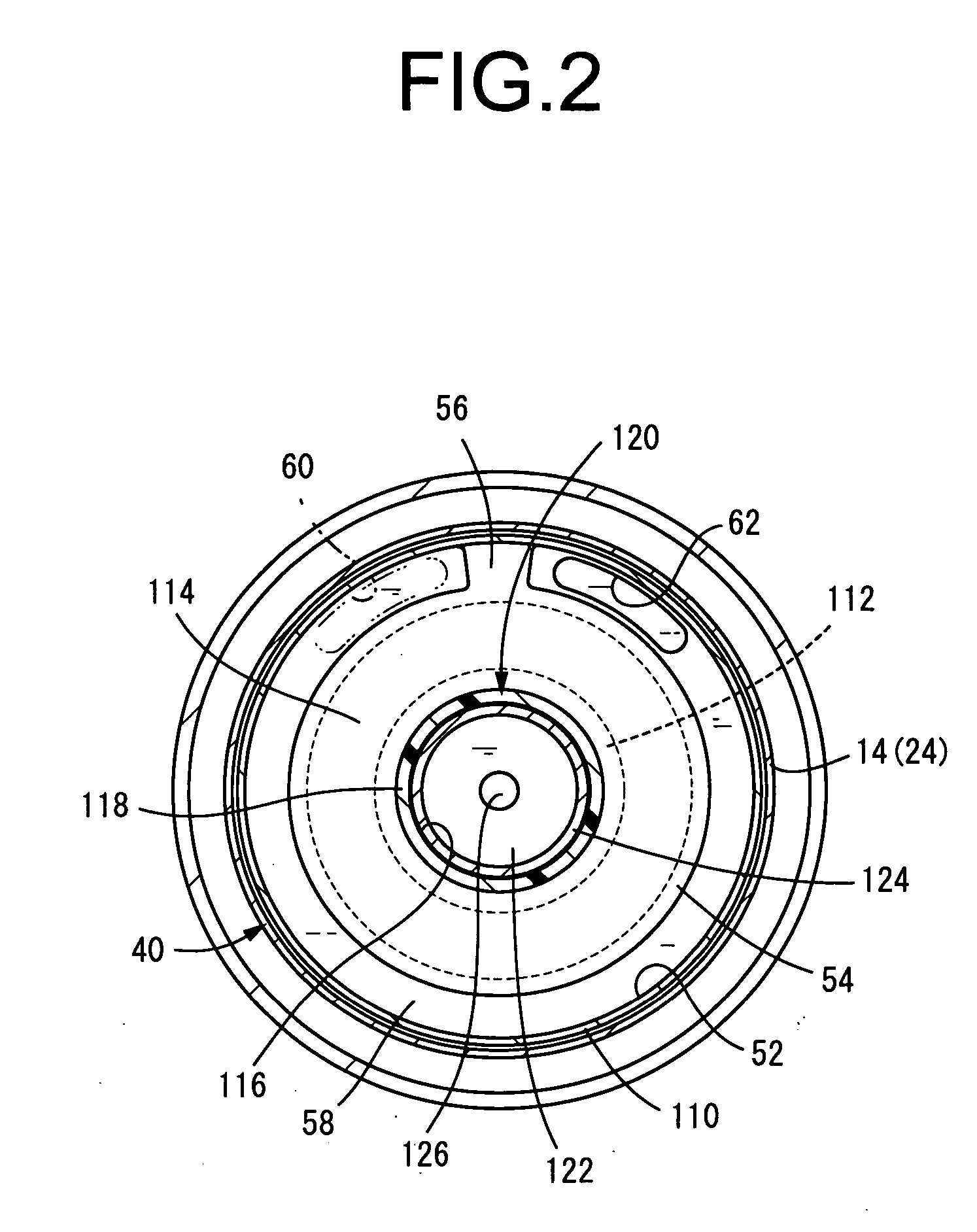

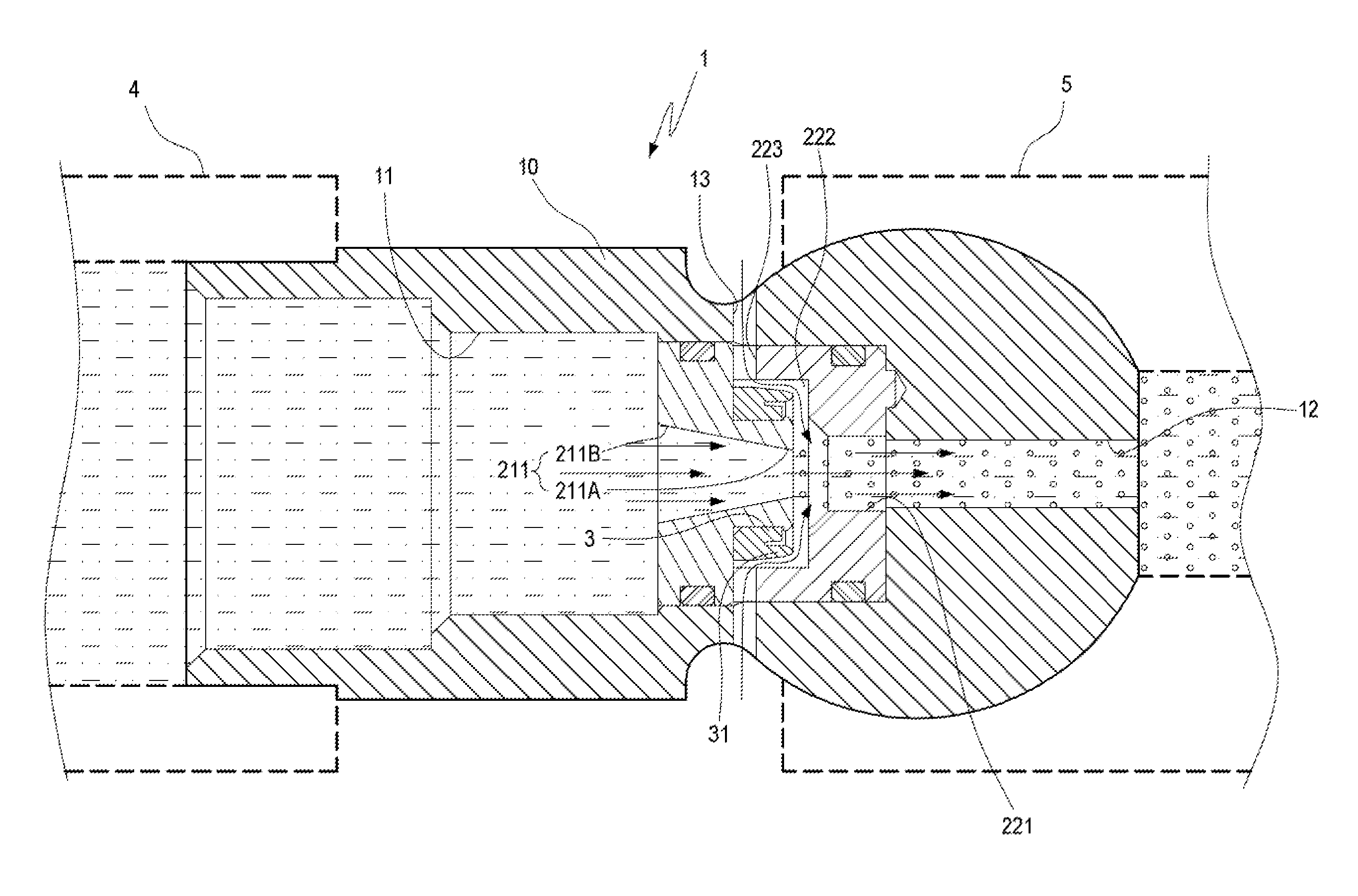

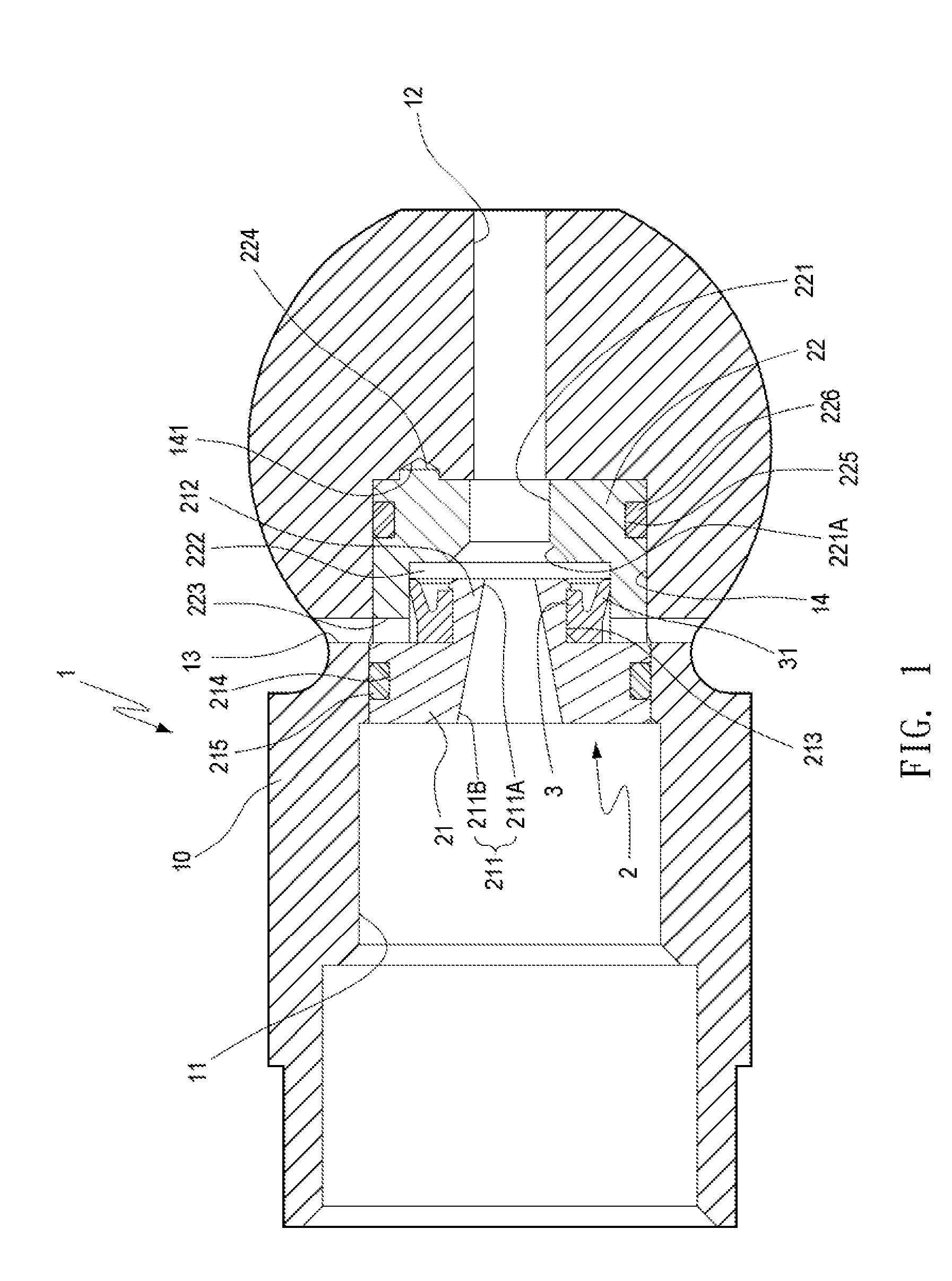

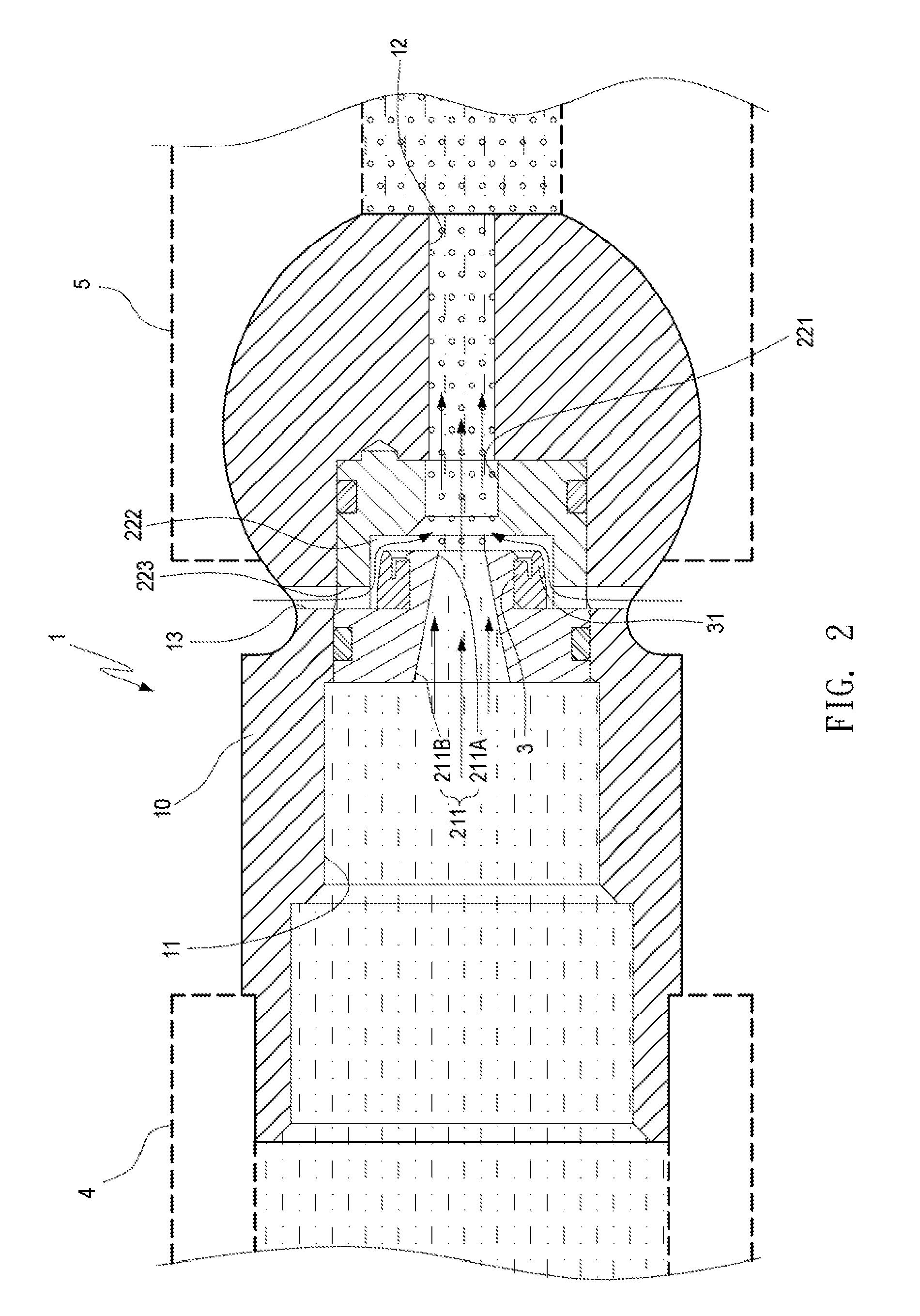

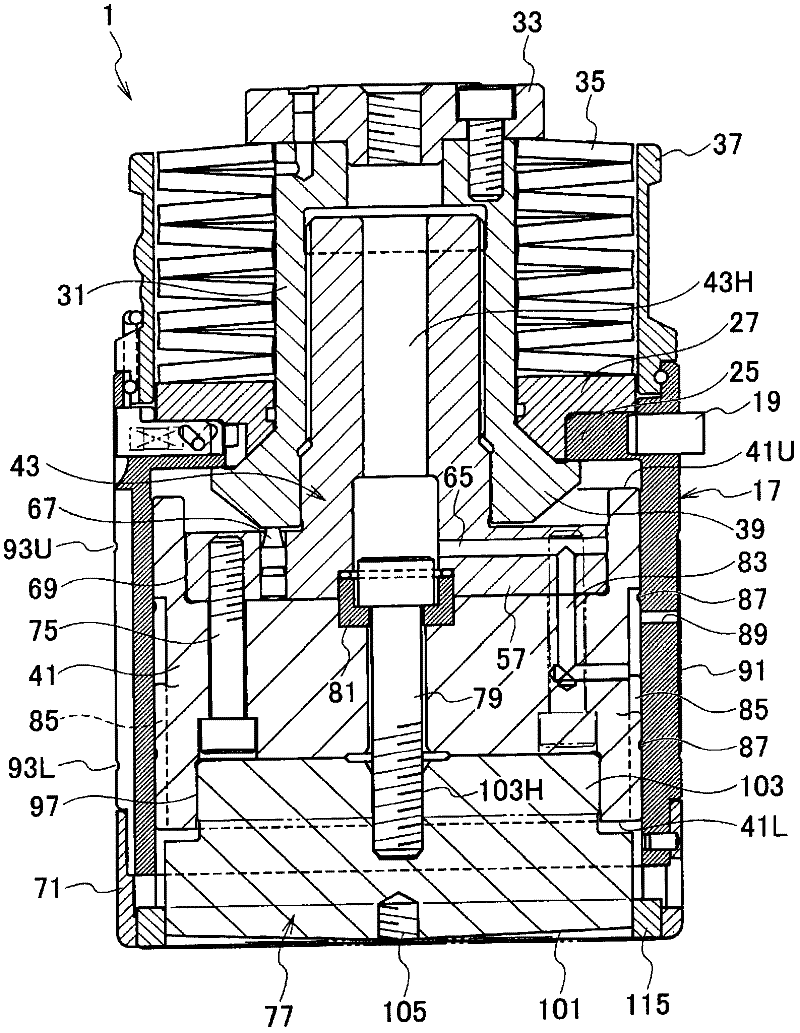

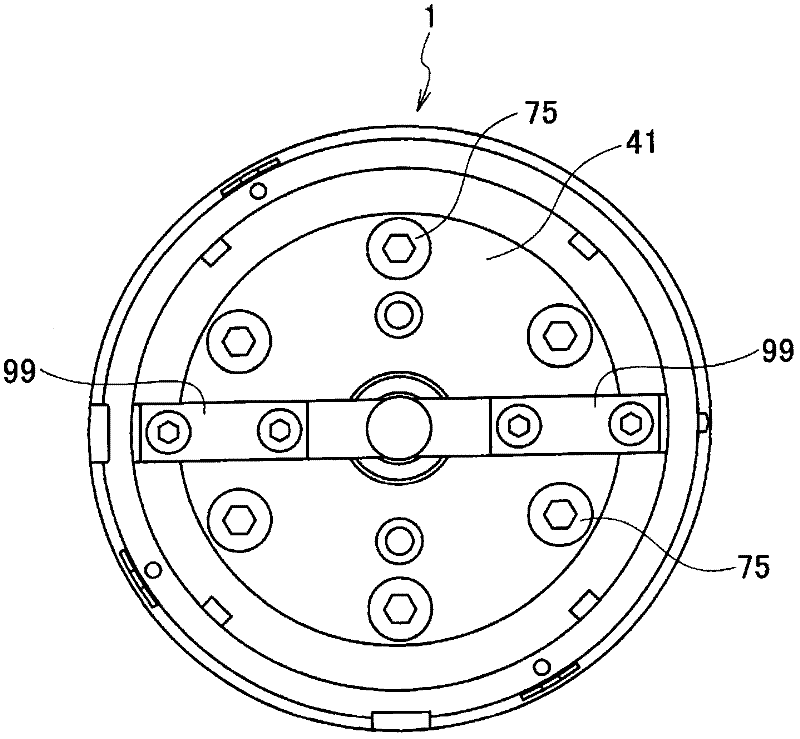

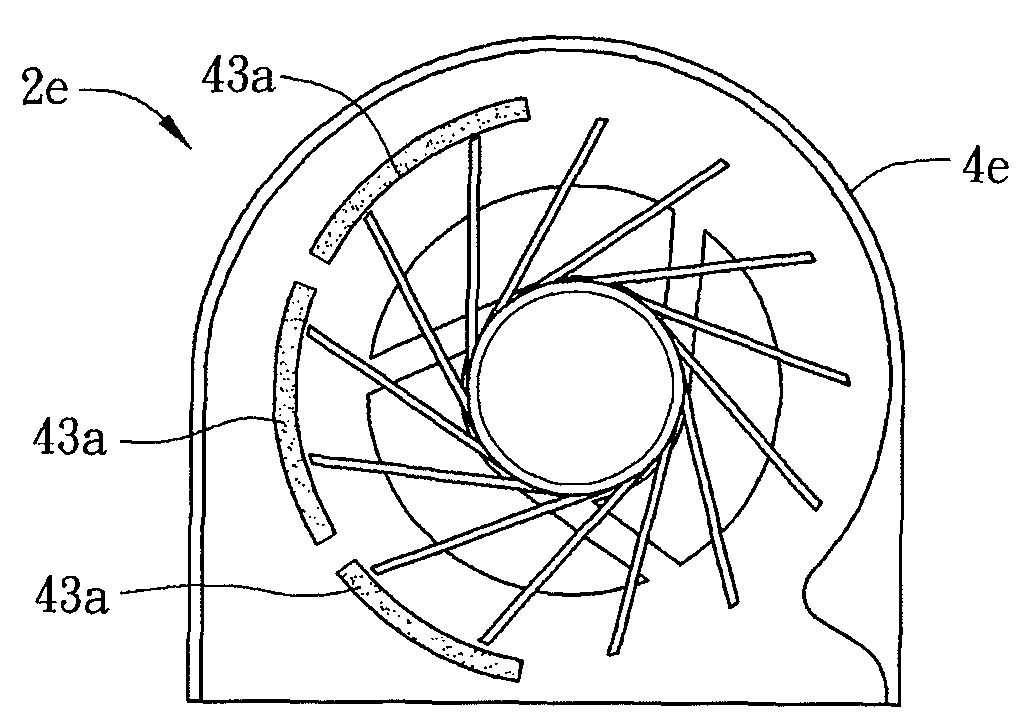

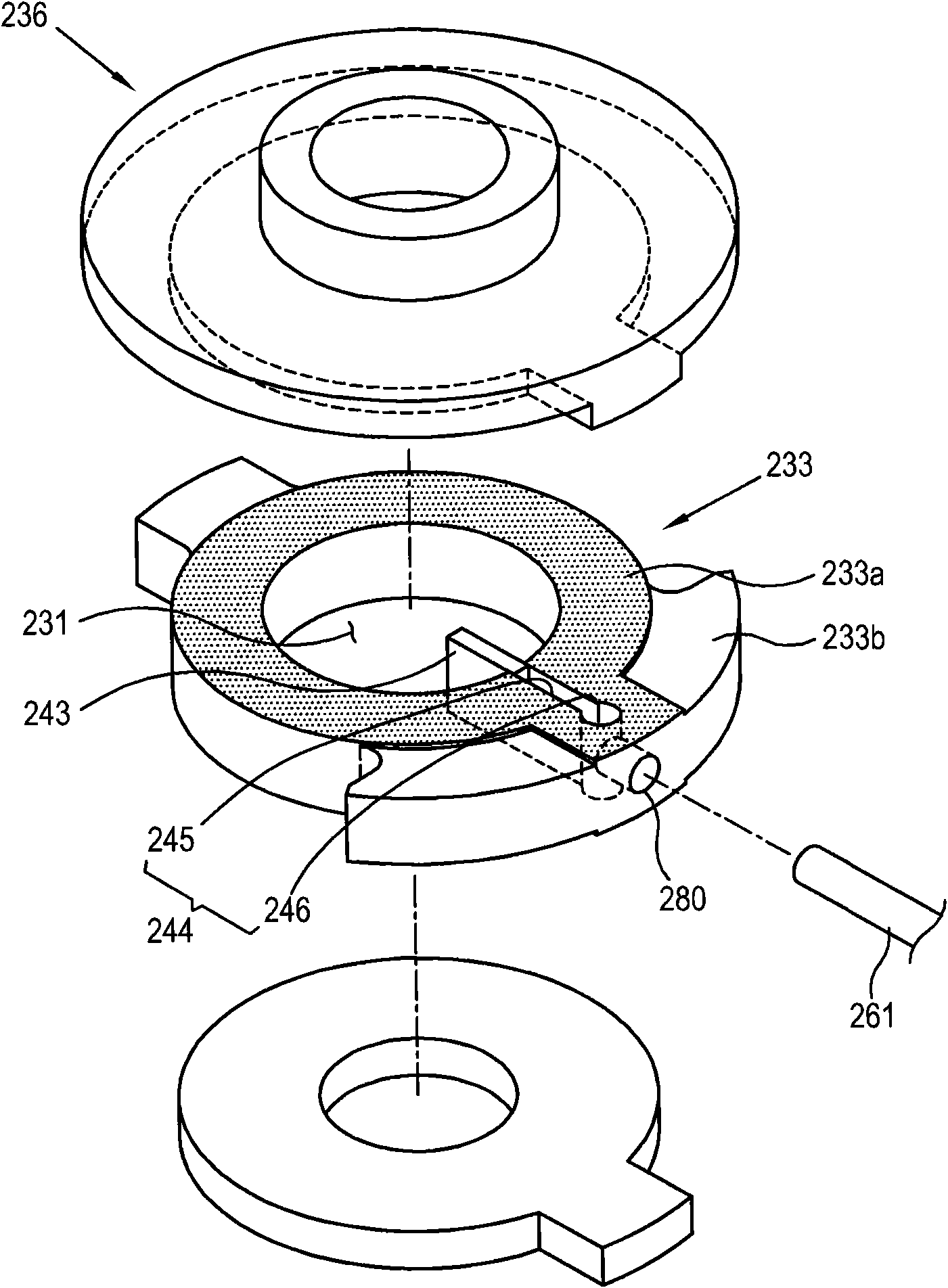

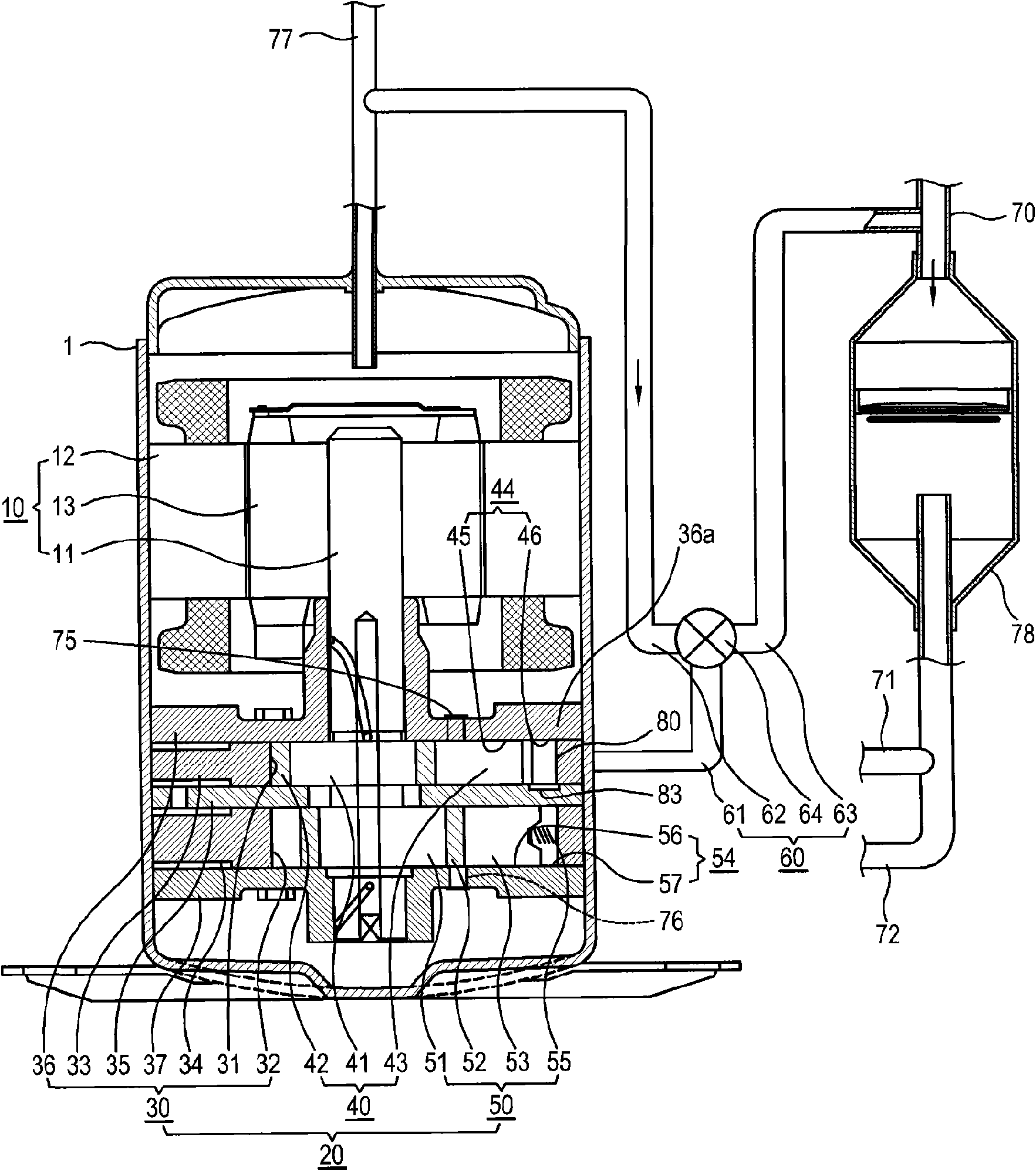

Capacity varying type rotary compressor and refrigeration system having the same

InactiveUS7798791B2Speed up coolingImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeLinear motionEngineering

A capacity varying type rotary compressor and a refrigeration system having the same are provided. The capacity varying type rotary compressor includes a casing that contains a certain amount of oil and maintains a discharge pressure state; a motor installed in the casing that generates a driving force; one or more cylinder assembly fixed in the casing, having a compression space that compresses a refrigerant by a rolling piston that performs an orbit motion and a vane that performs a linear motion by contacting the rolling piston, and having a vane pressure chamber formed at a rear side of the vane that implements a normal driving as the vane contacts the rolling piston or a saving driving as the vane is separated from the rolling piston; and a mode switching device that selectively supplies a suction pressure or a discharge pressure to the vane pressure chamber of the cylinder assembly according to a driving mode.

Owner:LG ELECTRONICS INC

Capacity Varying Type Rotary Compressor and Refrigeration System Having the Same

InactiveUS20080193310A1Speed up coolingImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringCooling capacity

A capacity varying type rotary compressor and a refrigeration system having the same. The capacity varying type rotary compressor comprises a casing containing a certain amount of oil and maintaining a discharge pressure state; a motor installed in the casing and generating a driving force; one or more cylinder assembly fixed in the casing, having a compression space for compressing a refrigerant by a rolling piston that performs an orbit motion and a vane that performs a linear motion by contacting the rolling piston, and having a vane pressure chamber formed at a rear side of the vane, for implementing a normal driving as the vane contacts the rolling piston or implementing a saving driving as the vane is separated from the rolling piston; and a mode switching unit for selectively supplying suction pressure or a discharge pressure to the vane pressure chamber of the cylinder assembly according to a driving mode. An installation of pipes can be simplified, a capacity varying ability can be easily controlled even when the compressor is driven, and the valve has less cooling capability loss thereby to enhance a driving efficiency. Furthermore, since the refrigeration system can implement an easy mode switching, comfort and energy saving are enhanced. Also, an interference between the pipes is prevented, thereby minimizing the refrigeration system and enhancing an assembly characteristic. Additionally, since the number of the valves of the refrigeration system is decreased, a production cost is reduced.

Owner:LG ELECTRONICS INC

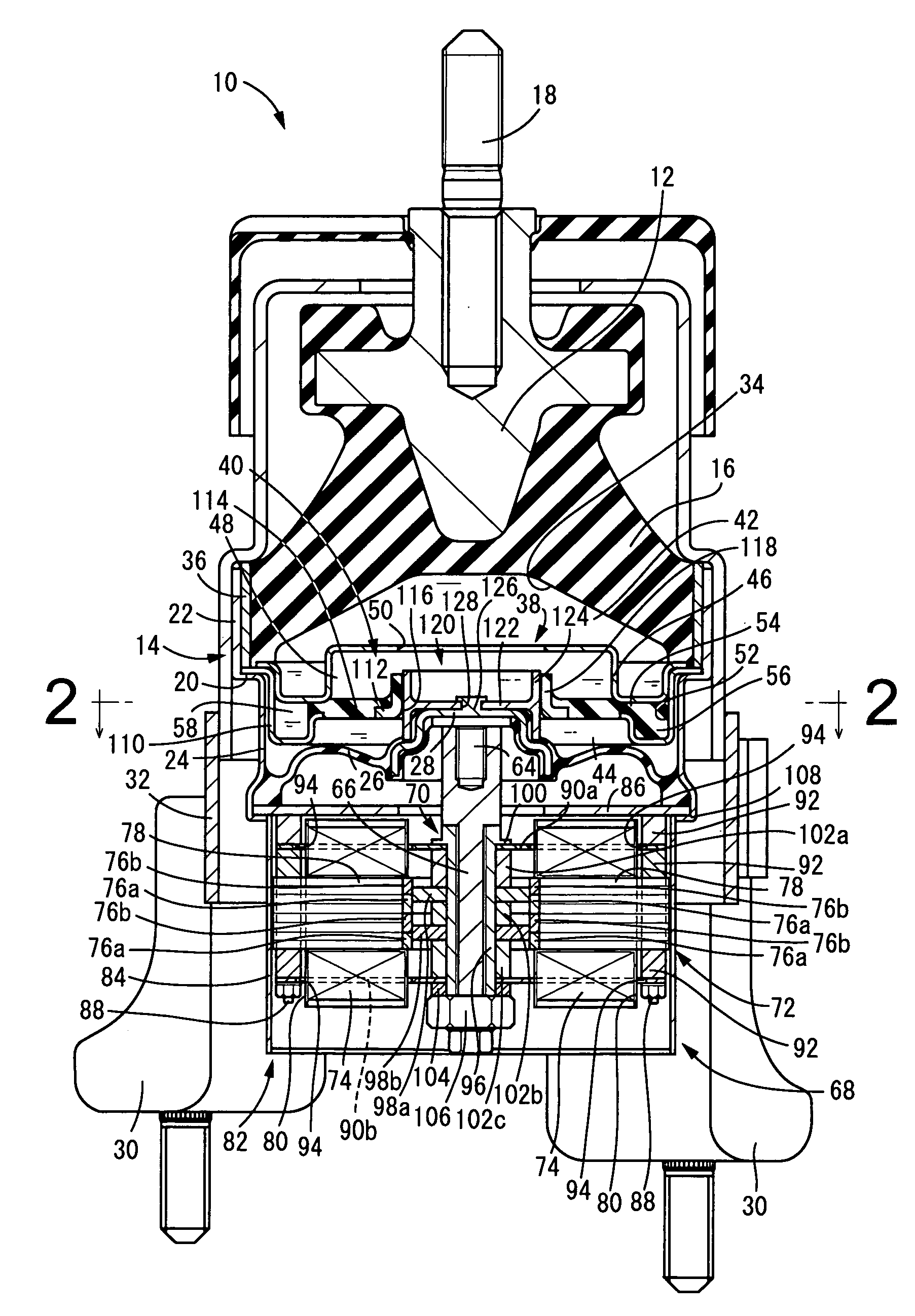

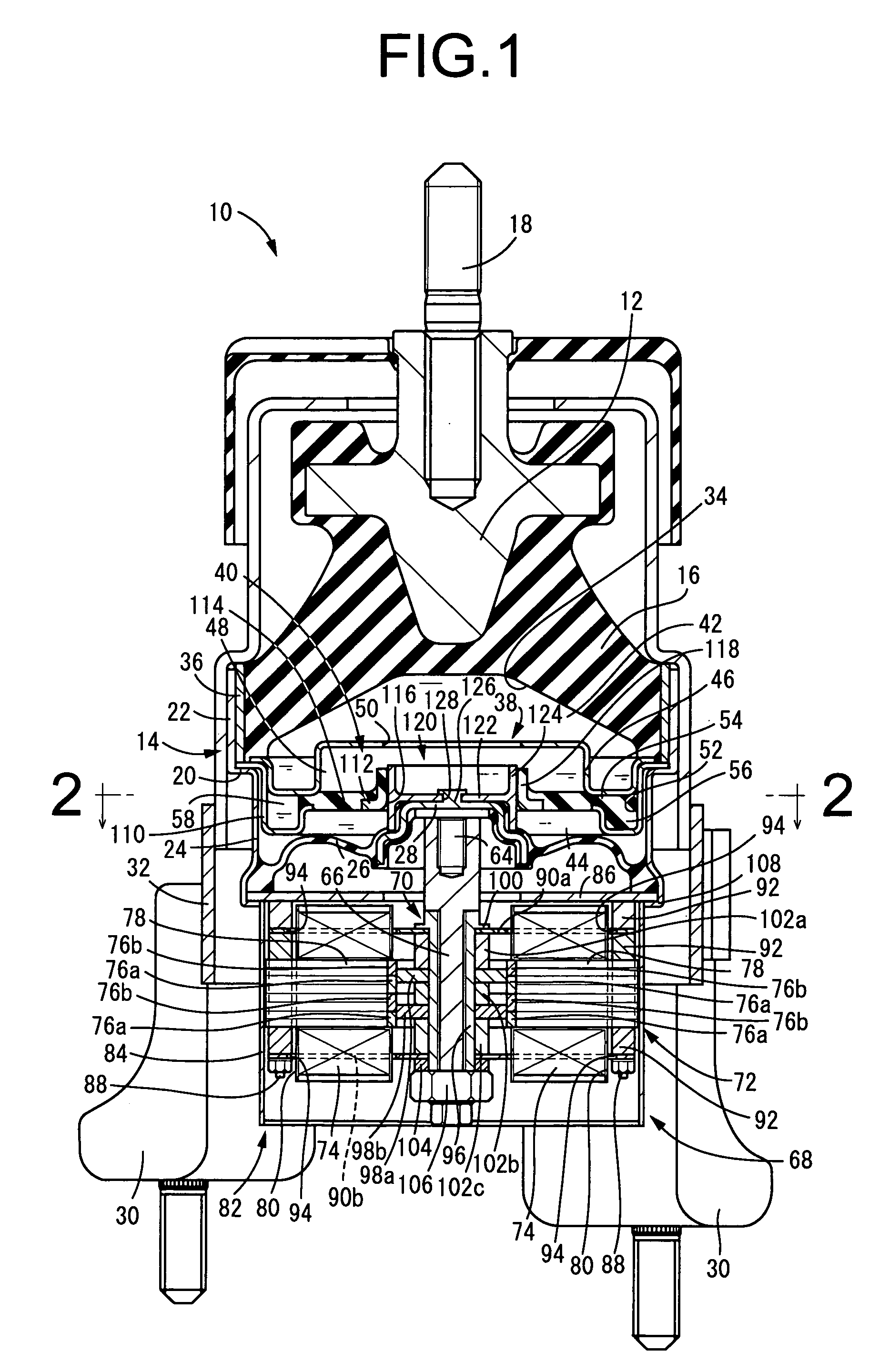

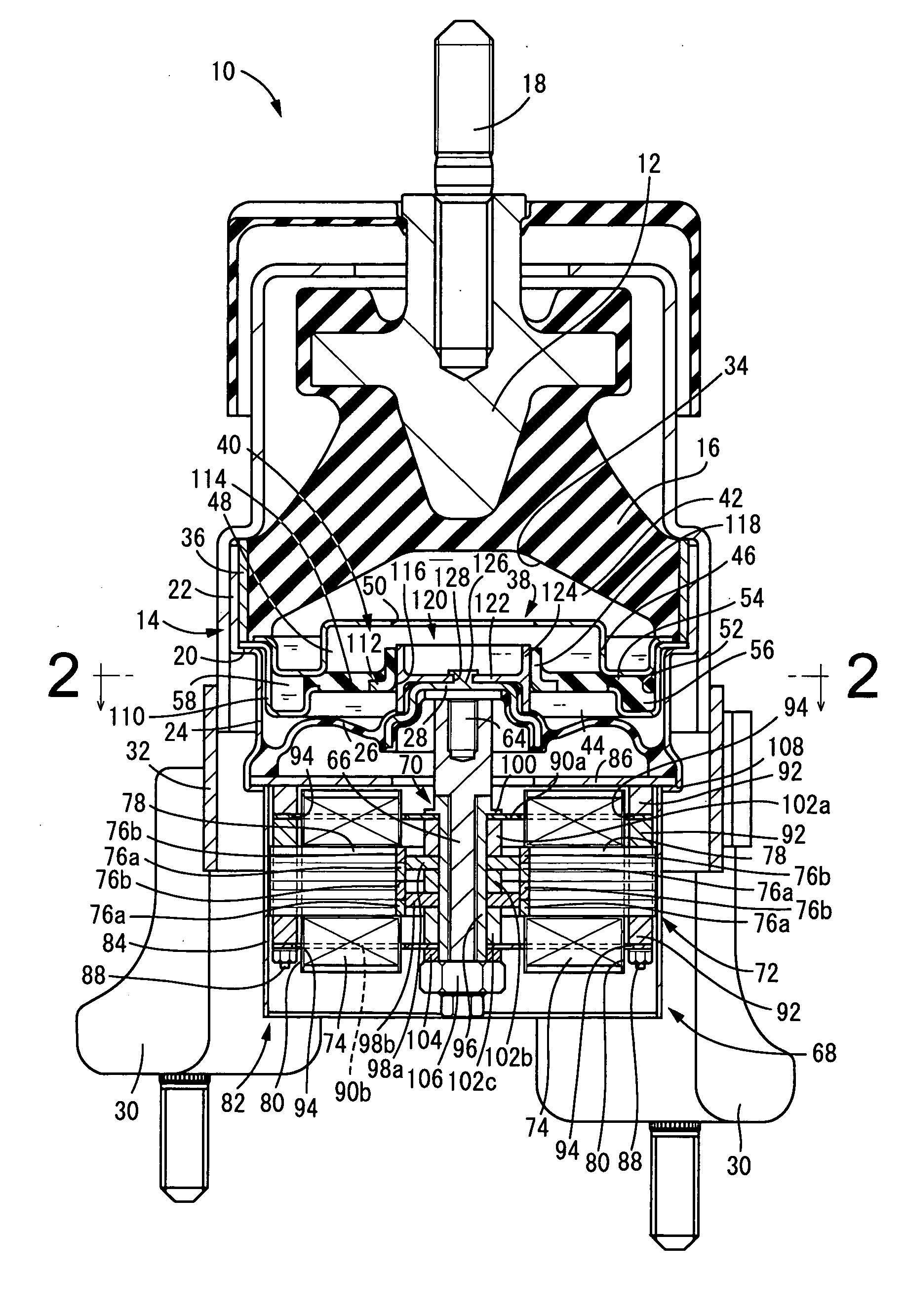

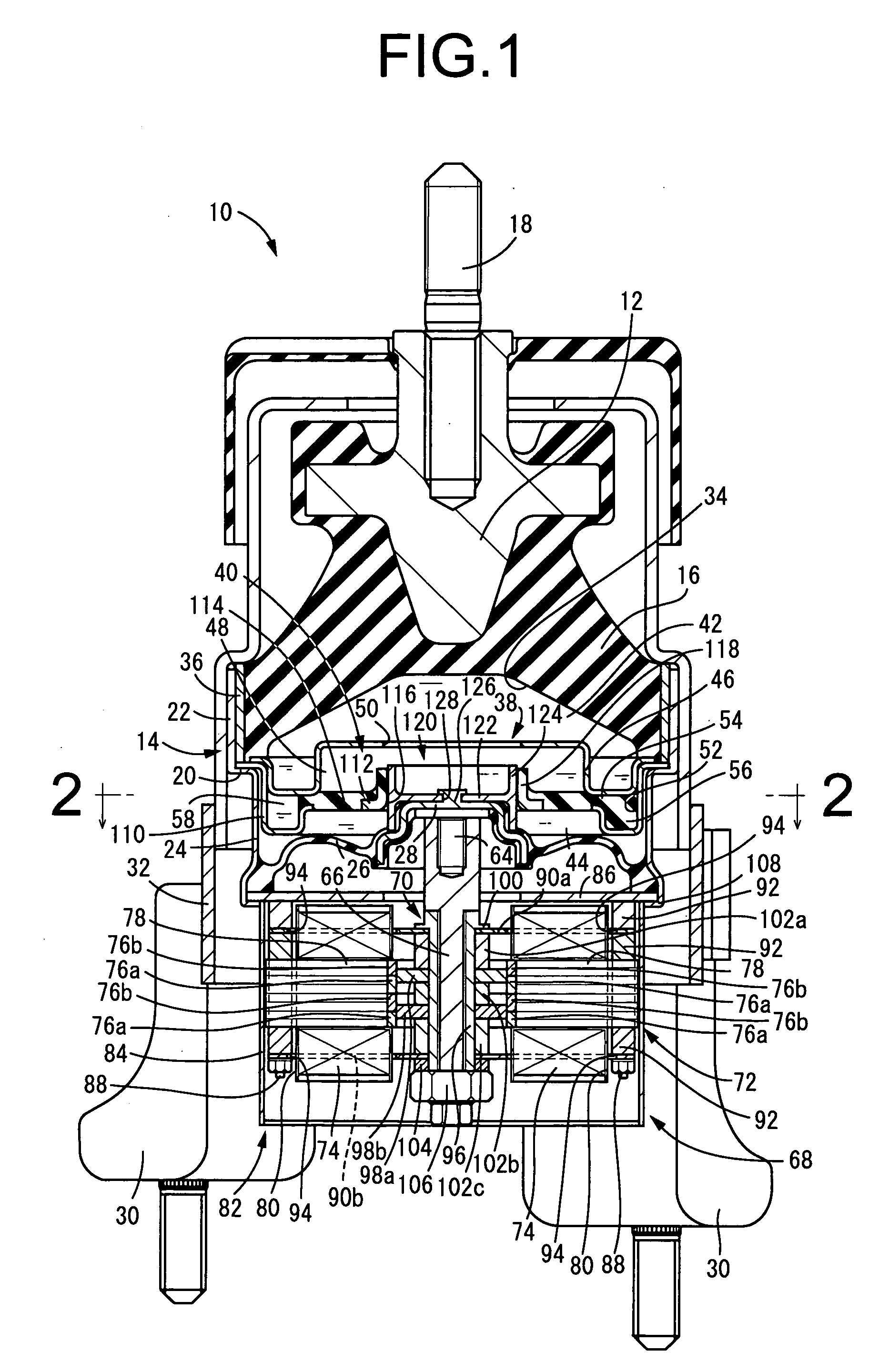

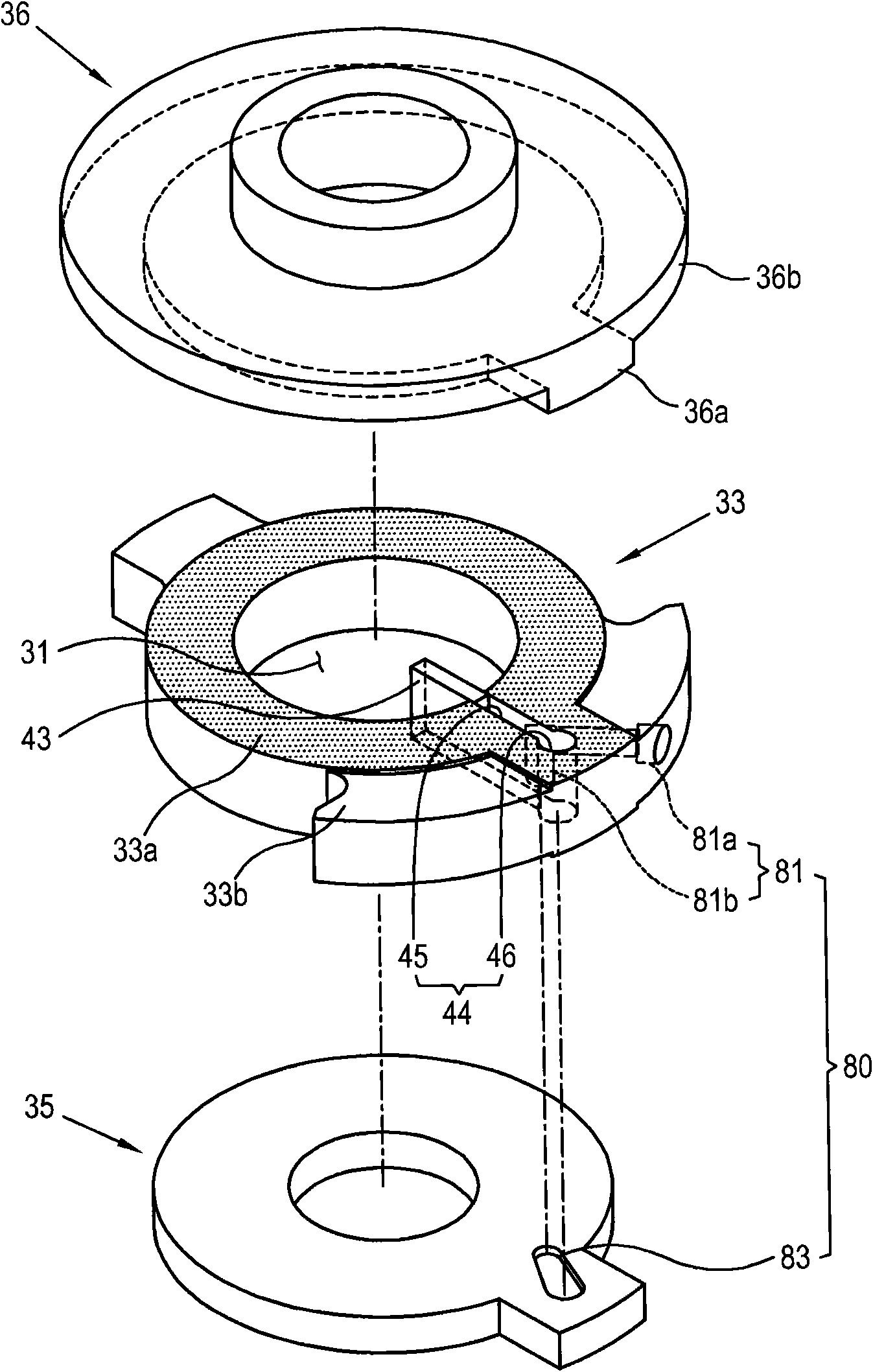

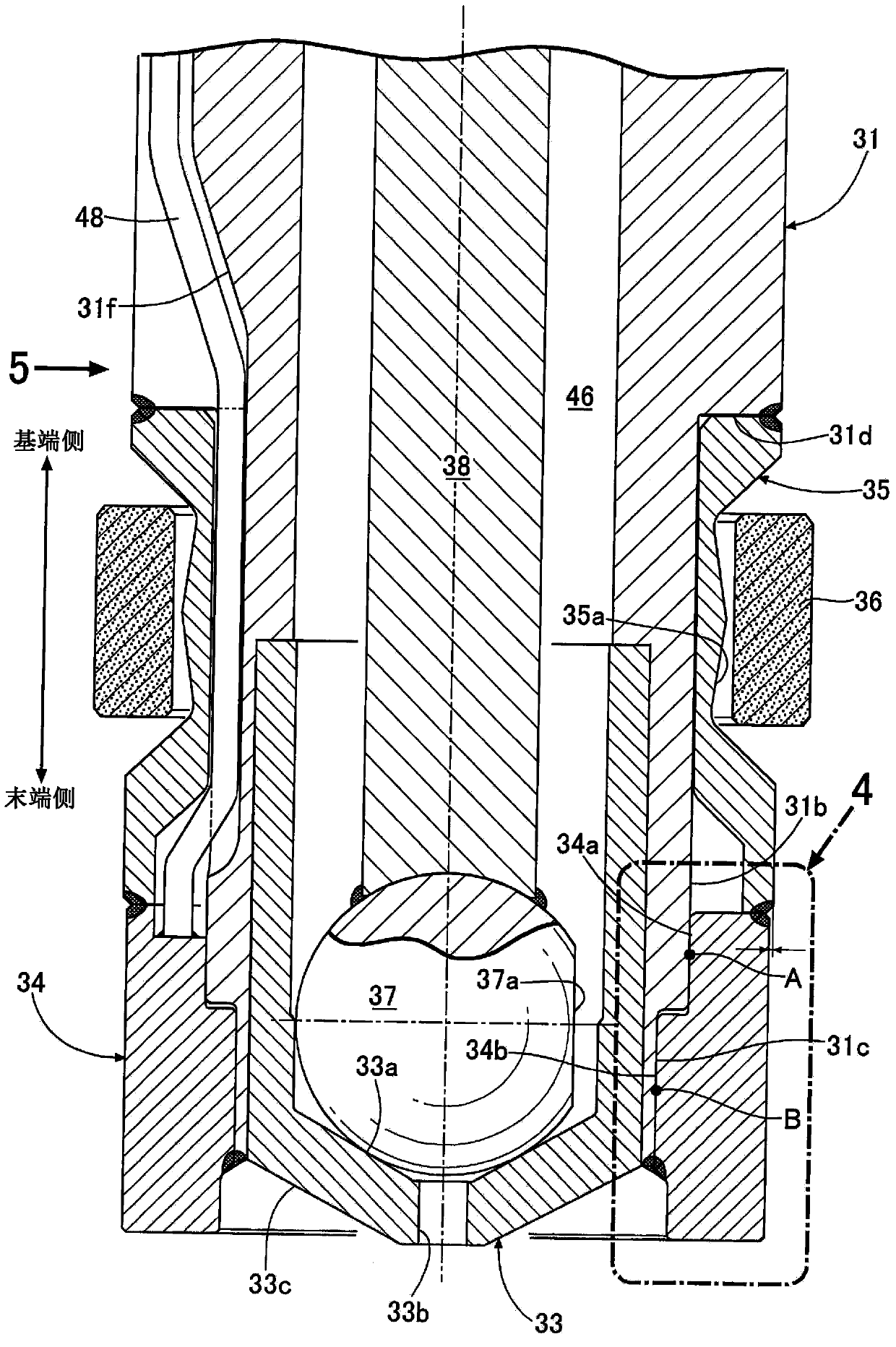

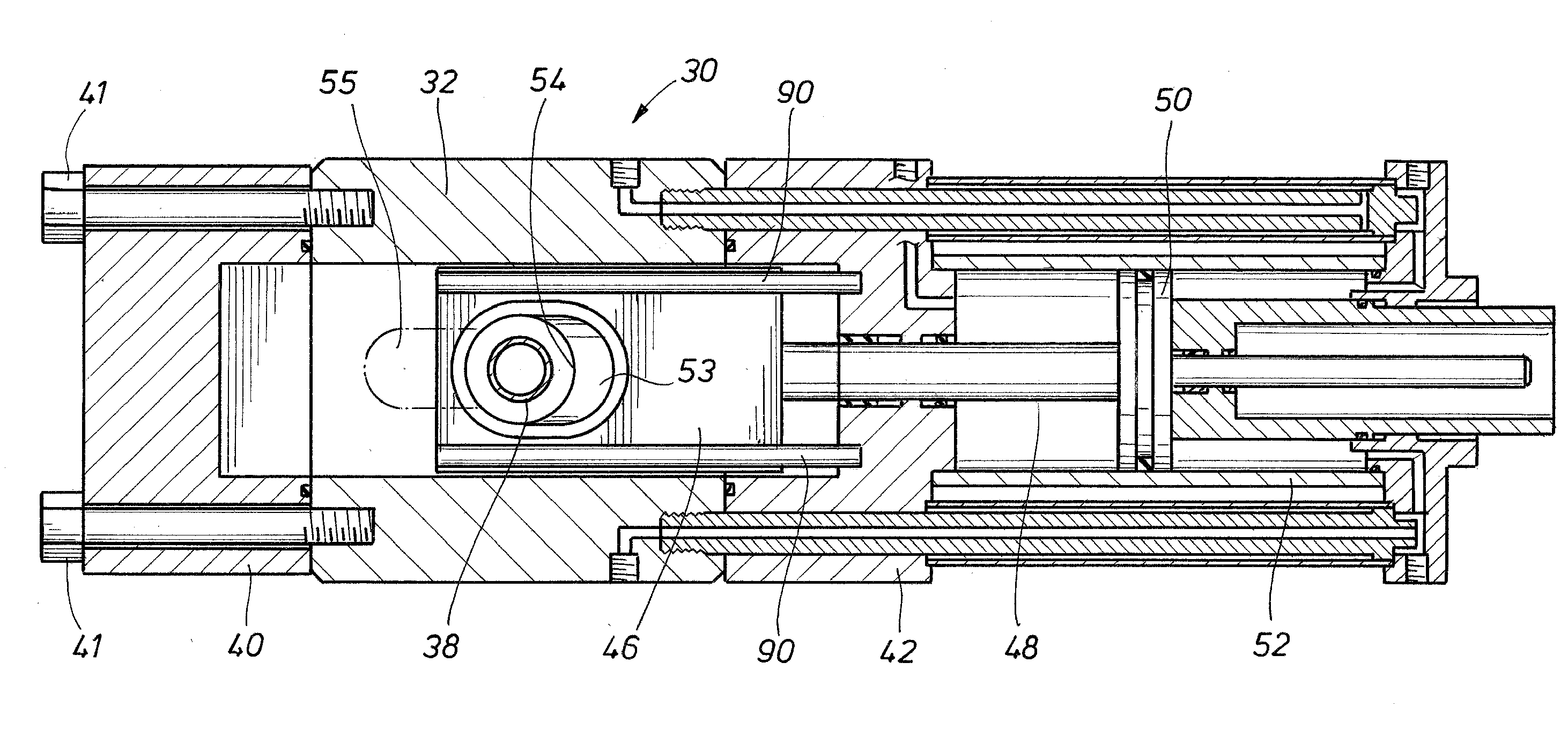

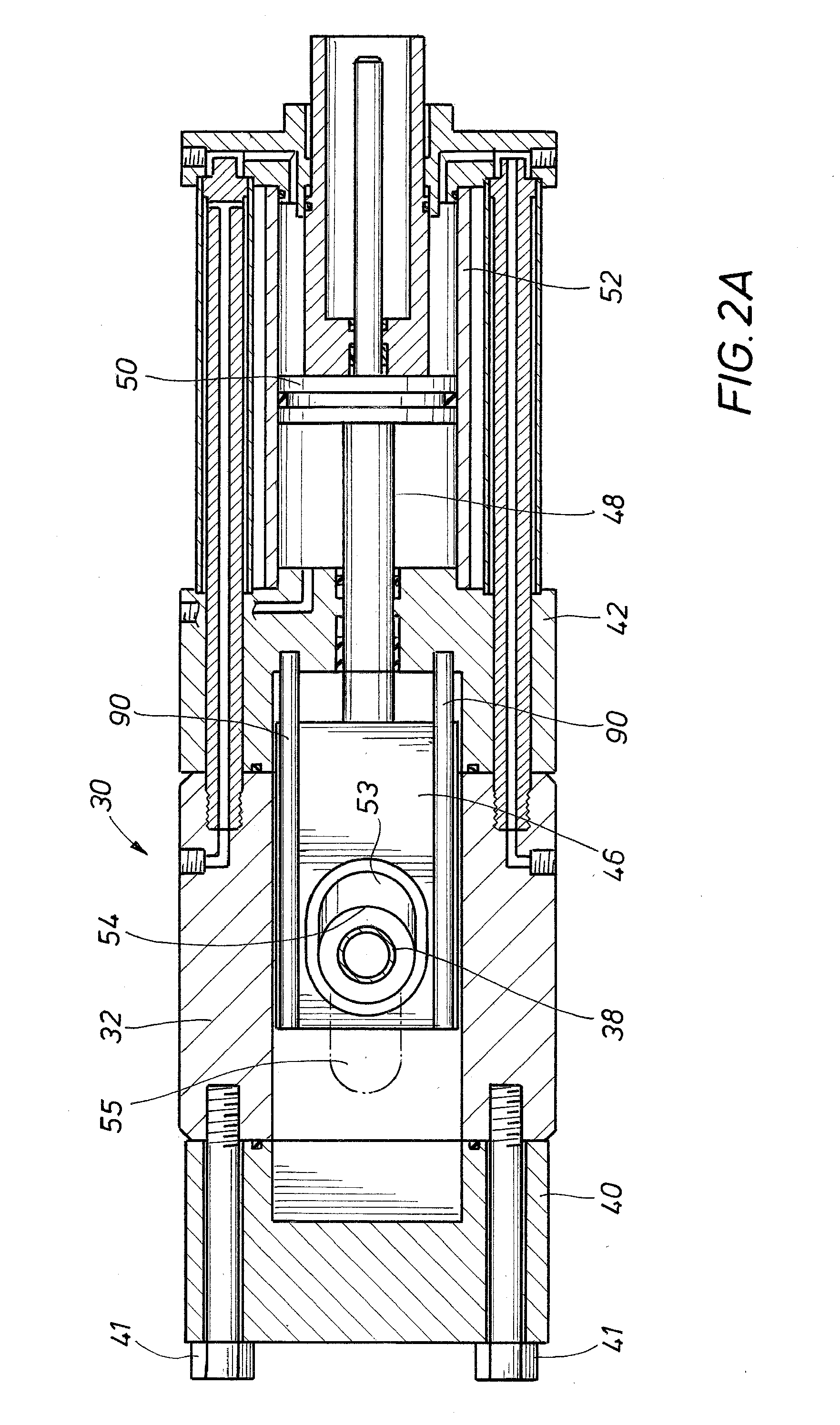

Fluid-filled active damping apparatus

InactiveUS7255335B2Easy maintenanceEasy to manufactureMachine framesLiquid springsElastomerMechanical engineering

A fluid-filled active damping apparatus having a pressure receiving chamber partially defined by a rubber elastic body connecting a first and second mounting member; an oscillation plate defining a part of the pressure receiving chamber, and supported in a displaceable fashion; an electromagnetic actuator disposed on one side of the oscillation plate remote from the pressure receiving chamber, with its output member connected to the oscillation plate; an equilibrium chamber partially defined by a flexible diaphragm; and an orifice passage connecting the pressure receiving chamber and equilibrium chamber. A rigid annular guide member is disposed about the oscillation plate with a slight gap therebetween, such that these members are mutually displaceable in the axial direction. The guide member is elastically supported by and connected to the second mounting member via an elastic support member.

Owner:SUMITOMO RIKO CO LTD

Capacity varying type rotary compressor

InactiveUS7540727B2Simple structureImprove reliabilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeInterior spaceDischarge pressure

A capacity varying rotary compressor is provided. The compressor includes a cylinder mounted in a casing, and a vane pressure chamber provided at a rear side of a vane that divides an inner space of the cylinder into a suction chamber and a compression chamber. A pressure controlling unit supplies a discharge pressure or a suction pressure to the vane pressure chamber to thereby restrict or release a motion of the vane. A pressure leakage preventing unit couples the cylinder and bearings positioned at opposite sides of the cylinder to form the vane pressure chamber. A capacity to compress and discharge a refrigerant may be varied according to a load, thereby reducing power consumption of the compressor and simplifying assembly. Furthermore, pressure leakage from the vane pressure chamber may be prevented, thereby enhancing a capacity varying function.

Owner:LG ELECTRONICS INC

Fluid-filled active damping apparatus

InactiveUS20050275145A1Easy maintenanceEasy to manufactureMachine framesLiquid springsElastomerEngineering

A fluid-filled active damping apparatus having a pressure receiving chamber partially defined by a rubber elastic body connecting a first and second mounting member; an oscillation plate defining a part of the pressure receiving chamber, and supported in a displaceable fashion; an electromagnetic actuator disposed on one side of the oscillation plate remote from the pressure receiving chamber, with its output member connected to the oscillation plate; an equilibrium chamber partially defined by a flexible diaphragm; and an orifice passage connecting the pressure receiving chamber and equilibrium chamber. A rigid annular guide member is disposed about the oscillation plate with a slight gap therebetween, such that these members are mutually displaceable in the axial direction. The guide member is elastically supported by and connected to the second mounting member via an elastic support member.

Owner:SUMITOMO RIKO CO LTD

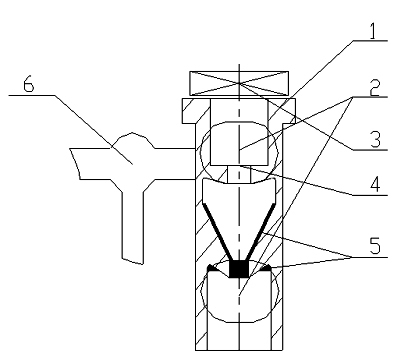

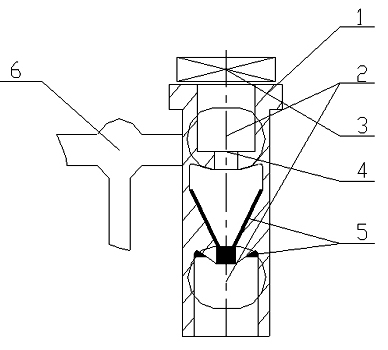

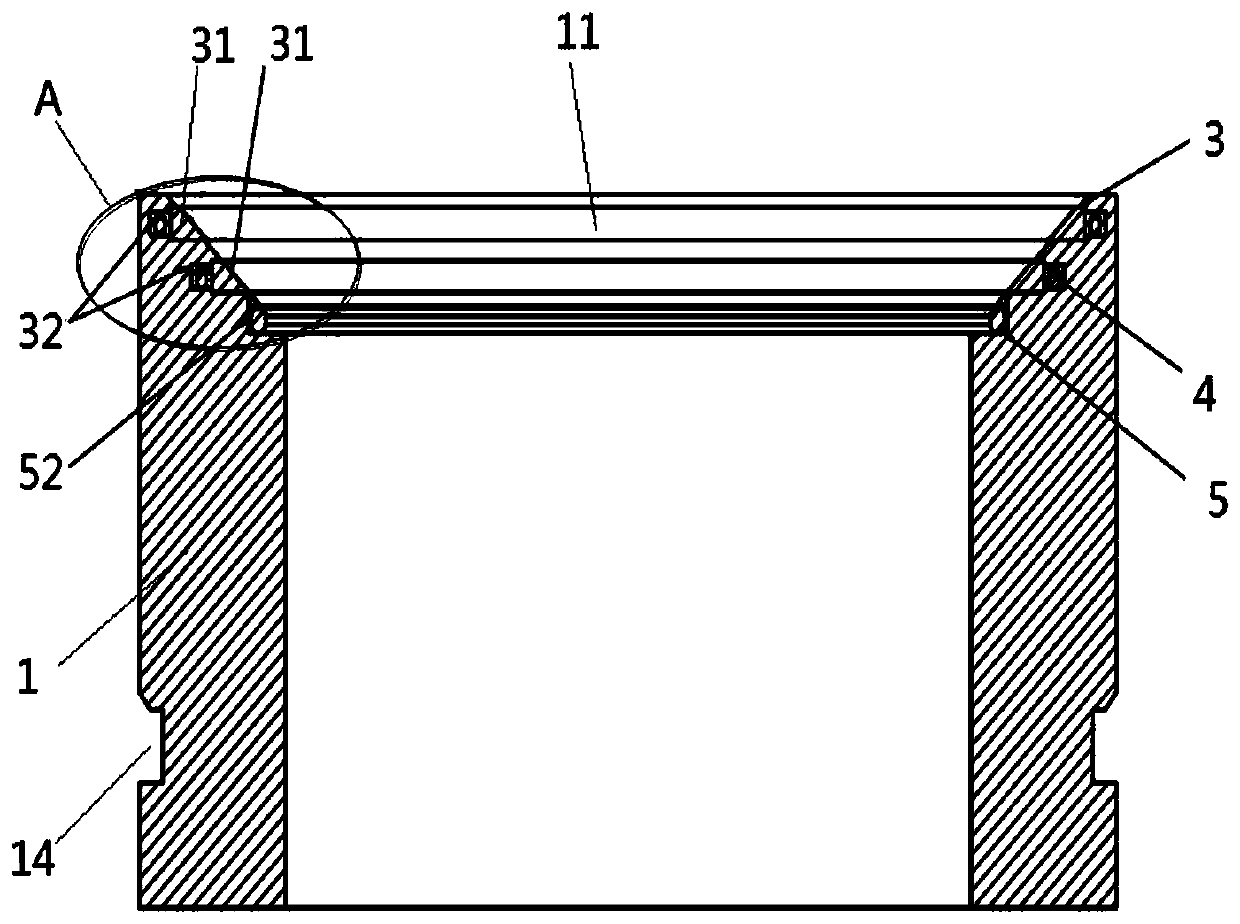

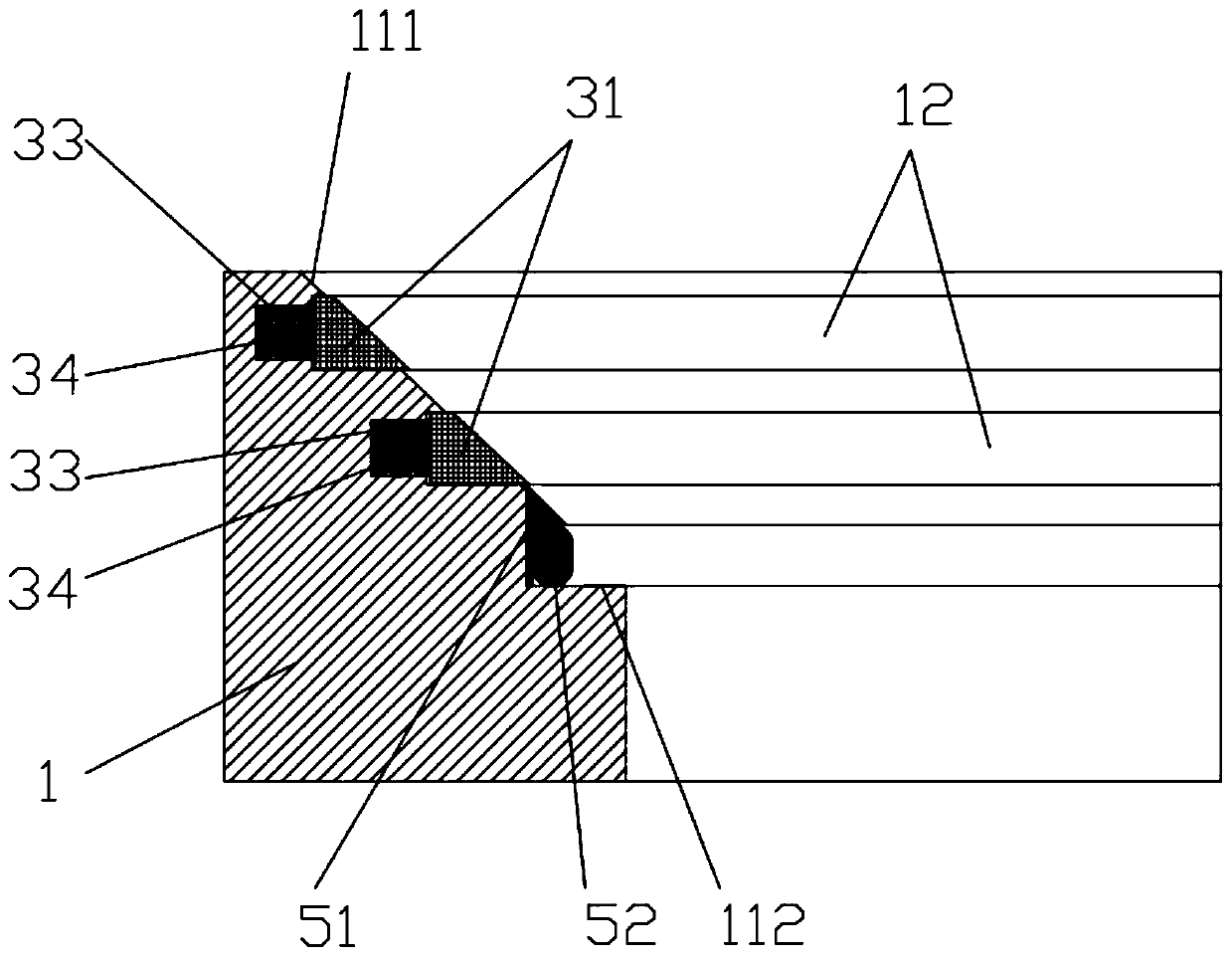

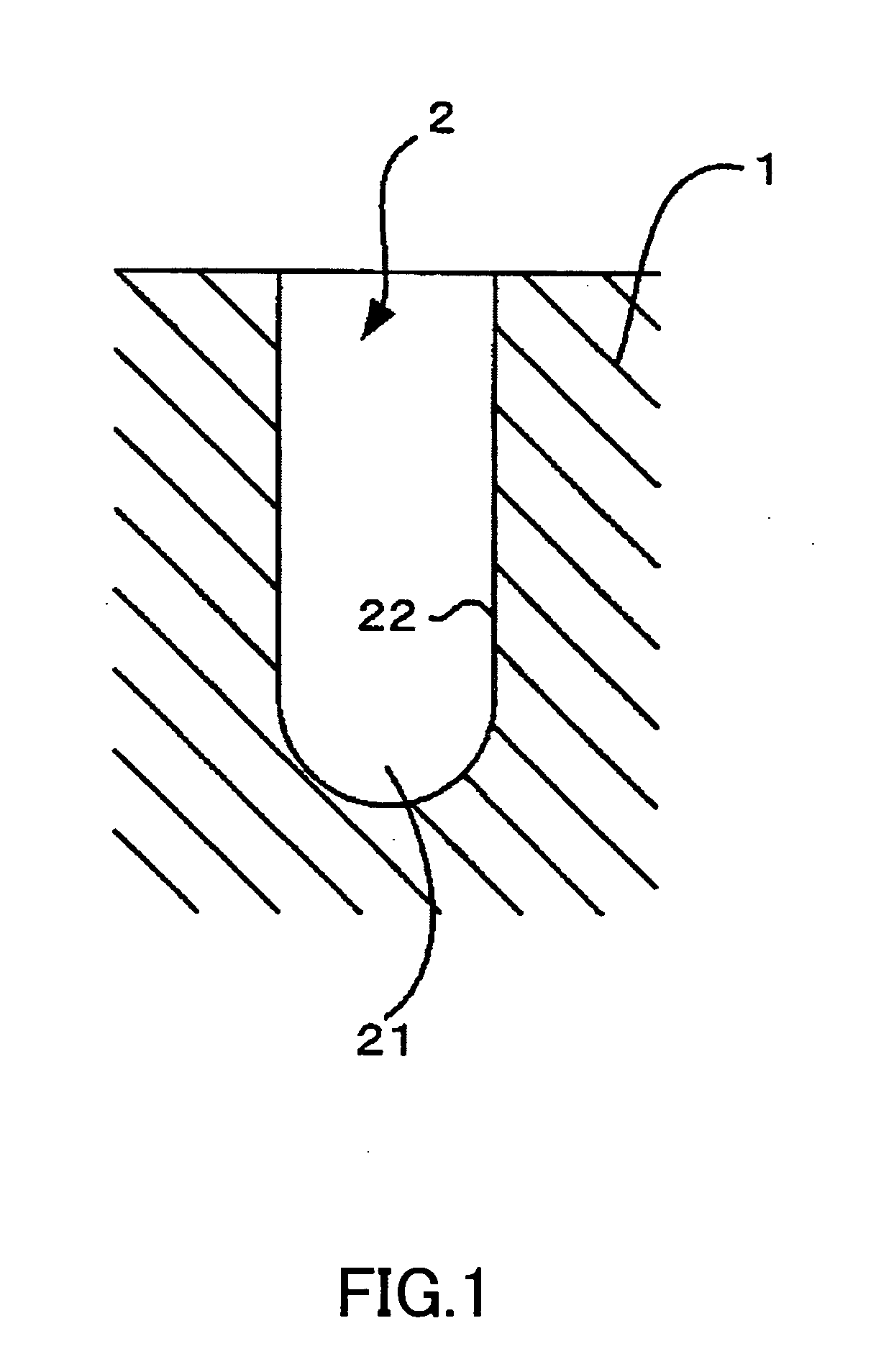

Casting process of valve casing

InactiveCN101947641AAvoid pressure leaksAvoid Casting DefectsFoundry mouldsFoundry coresFoundryIntermediate frequency

The invention discloses a casting process of a valve casing. During smelting, stainless steel 1Cr13 foundry returns and low-carbon steel scraps are used as raw materials and smelted into casting molten steel in an intermediate frequency furnace; during casting, a resin sand two-bin modeling is adopted for a valve casing casting mould (1) to manufacture a core, during core manufacturing, an intermediate connection part of a mud core No.1 is connected by a ceramic pipe (4), chromite sand (5) with the thickness of 15mm is placed on a part that is easy to leak by pressure, two heat insulation dead heads (2) in specification of 80*120*120 are designed to be arranged on the valve casing casting mould (1), a shaped chiller (3) with the thickness of 20mm is designed to be arranged on a tail flange part and used for an upper bin and a lower bin by half respectively, vent holes of phi15 are pierced on the top of a flange, and a slag trap (6) with the height of 150mm is arranged on a connecting part between a transverse casting runner and an internal casting runner. The invention overcomes the casting defects of sanded vent holes, burning sand on surface, and the like, prevents the situation of leakage by pressure of the valve casing in a 69Bar pressure test due to more and complex mud cores, and meets the requirements of the valve casing on chemical composition and mechanical property.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

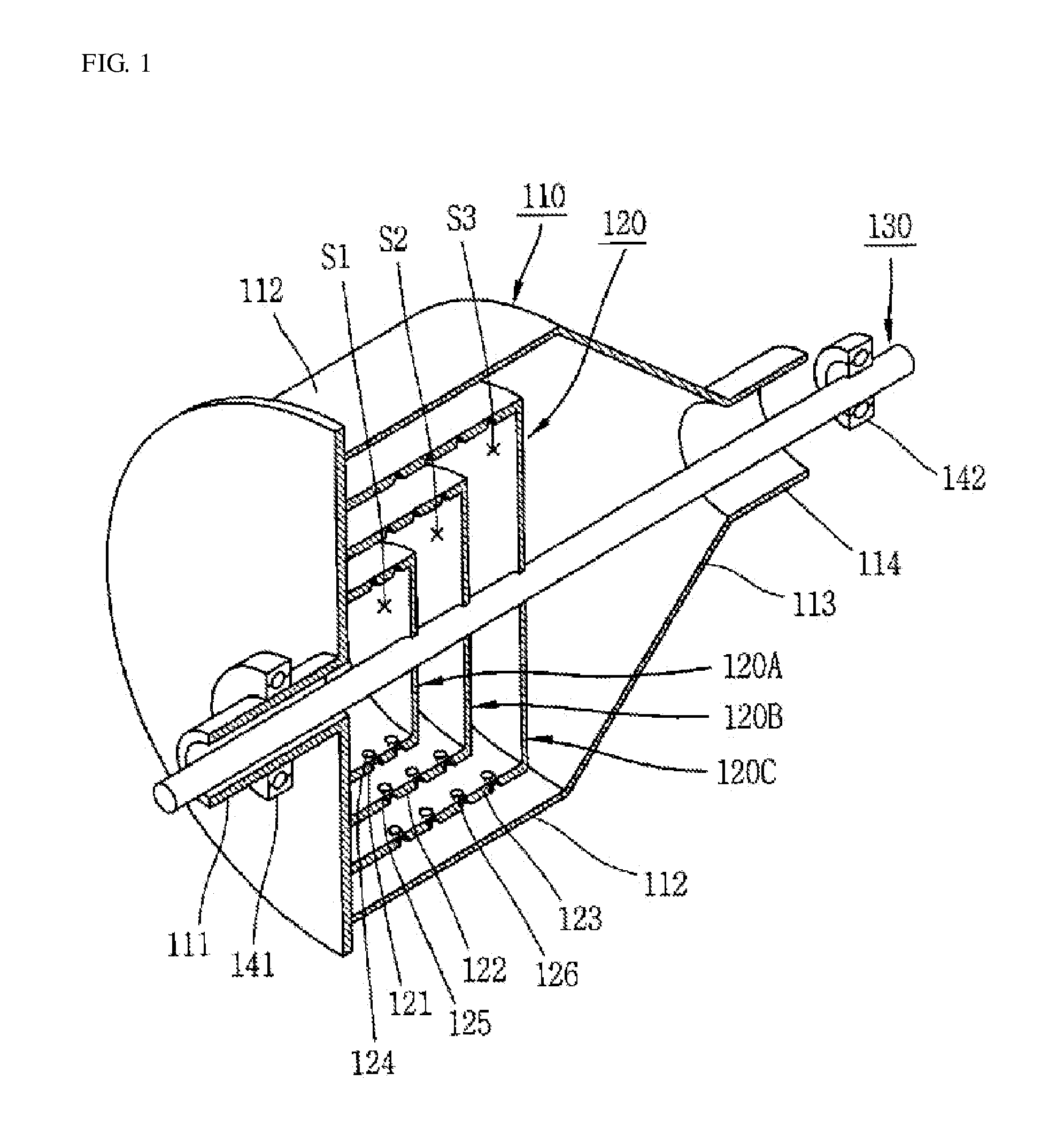

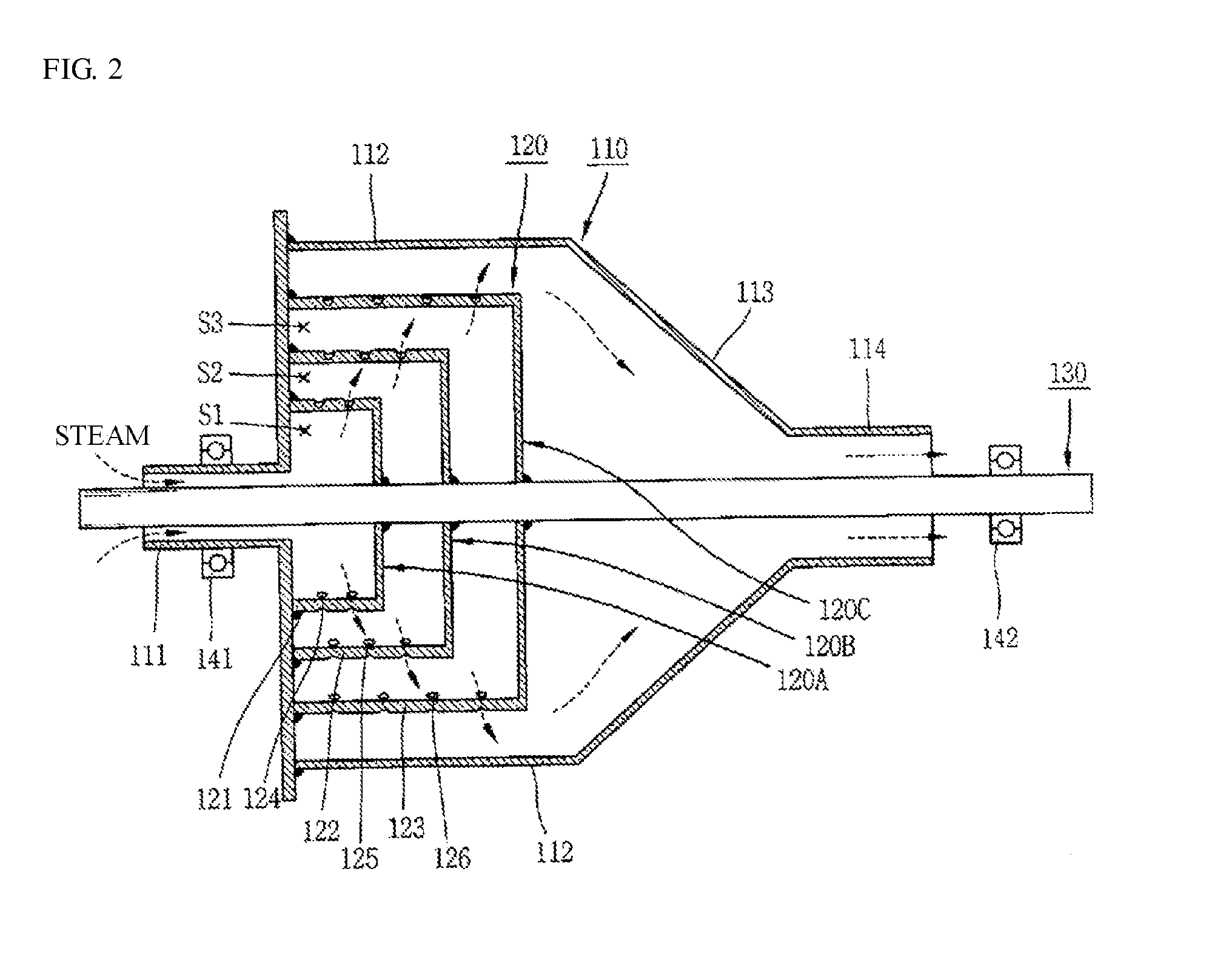

Reaction-type turbine

InactiveUS20120009055A1Reduce lossesGuaranteed uptimeReaction enginesEngine componentsManufacturing cost reductionTurbine

The present invention relates to a reaction-type turbine. The reaction-type turbine of the present invention is configured such that a jet and rotating unit and a turbine shaft rotate by the repulsive force generated when steam spurts from the jet and rotating unit, so as to generate propulsion force. Thus, the operating stability of a steam turbine can be maintained even when condensate water is mixed with the steam, and manufacturing costs can be significantly reduced. Further, in order to reduce a loss of energy, the flow resistance of the steam is remarkably reduced or pressure leakage is prevented, thereby obtaining a low-cost and high-efficiency turbine.

Owner:HK TURBINE

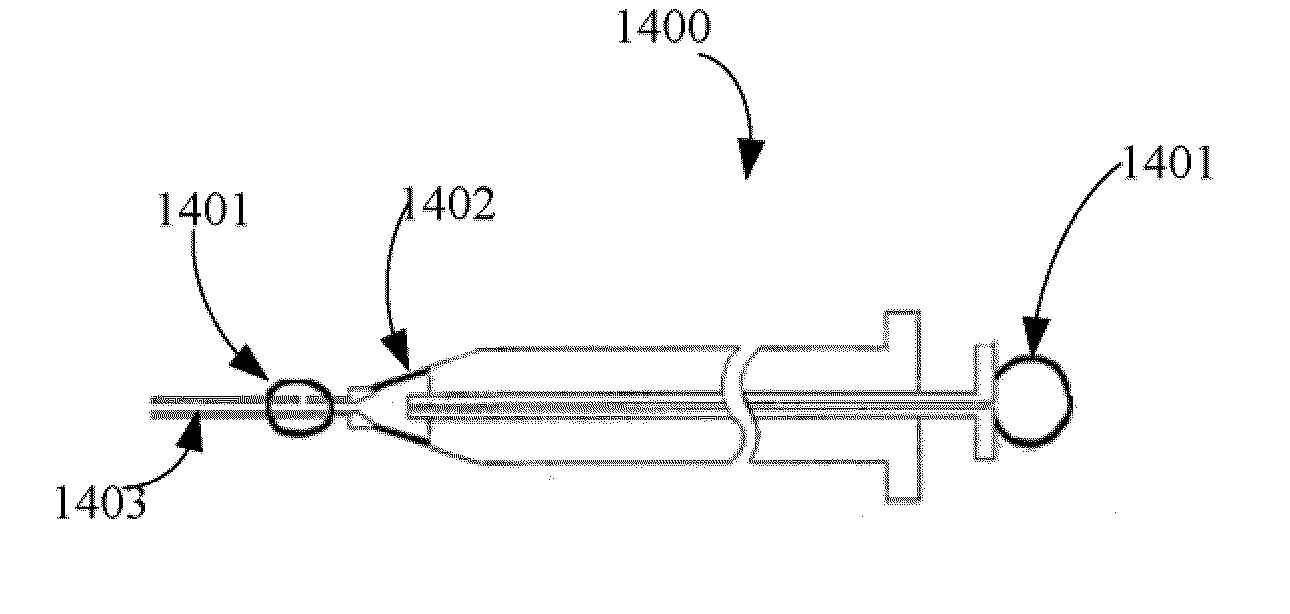

Pipette Device and Method of Manufacture and Use Thereof

InactiveUS20100209303A1Prevent leakageEasy to splitBurettes/pipettesMetal working apparatusPipetteEquilibrium control

The present invention provides a pipette device for moving or transferring micron quantities of fluid and cells, particularly oocytes / embryos, with a simplified pipette tip loading and unloading process. The present invention further provides a pipette device comprising a controller by which air pressure inside and outside of the controller can be intentionally balanced. Methods of manufacture and use of the pipette device of the present invention are also provided.

Owner:TAO JUN

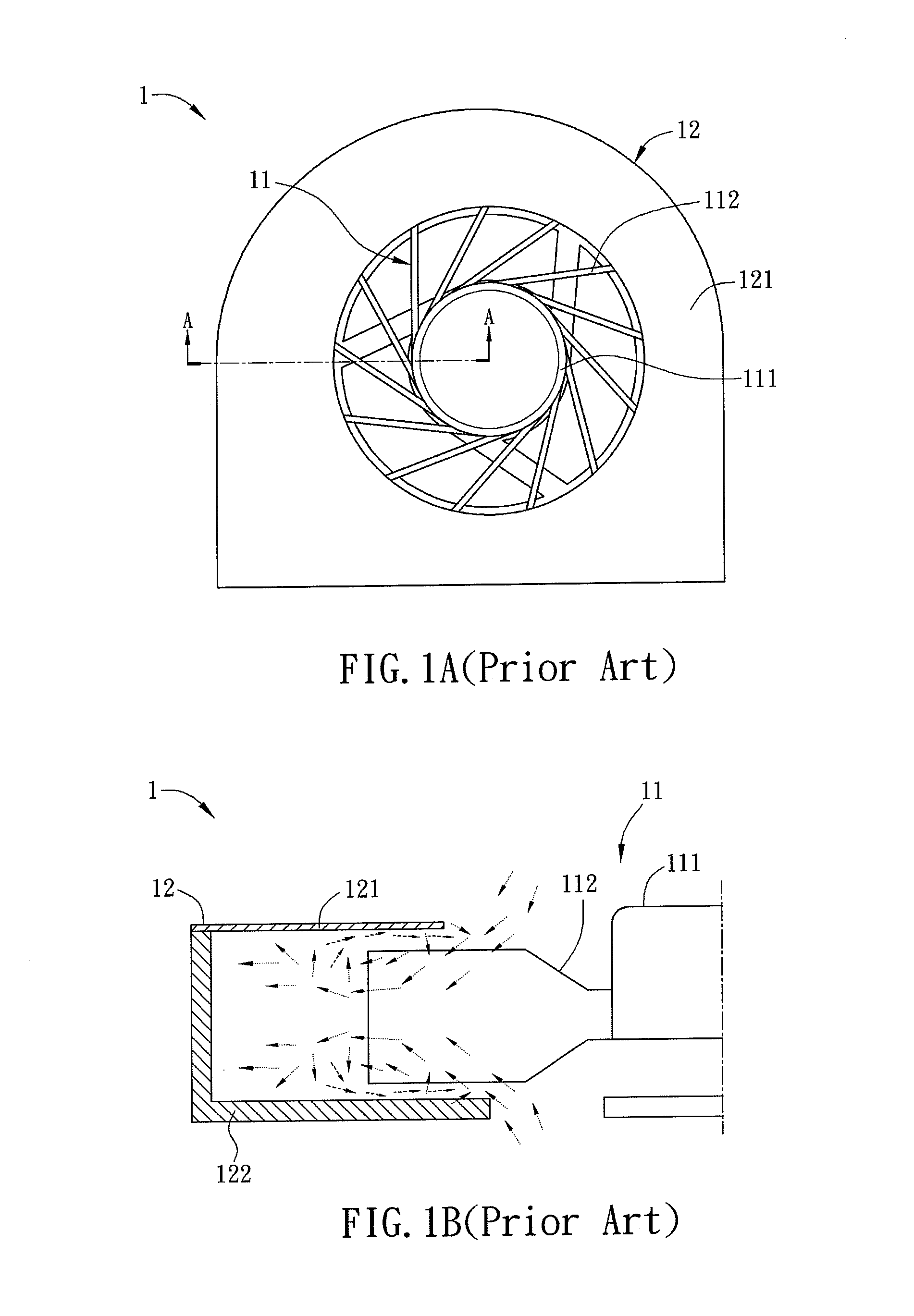

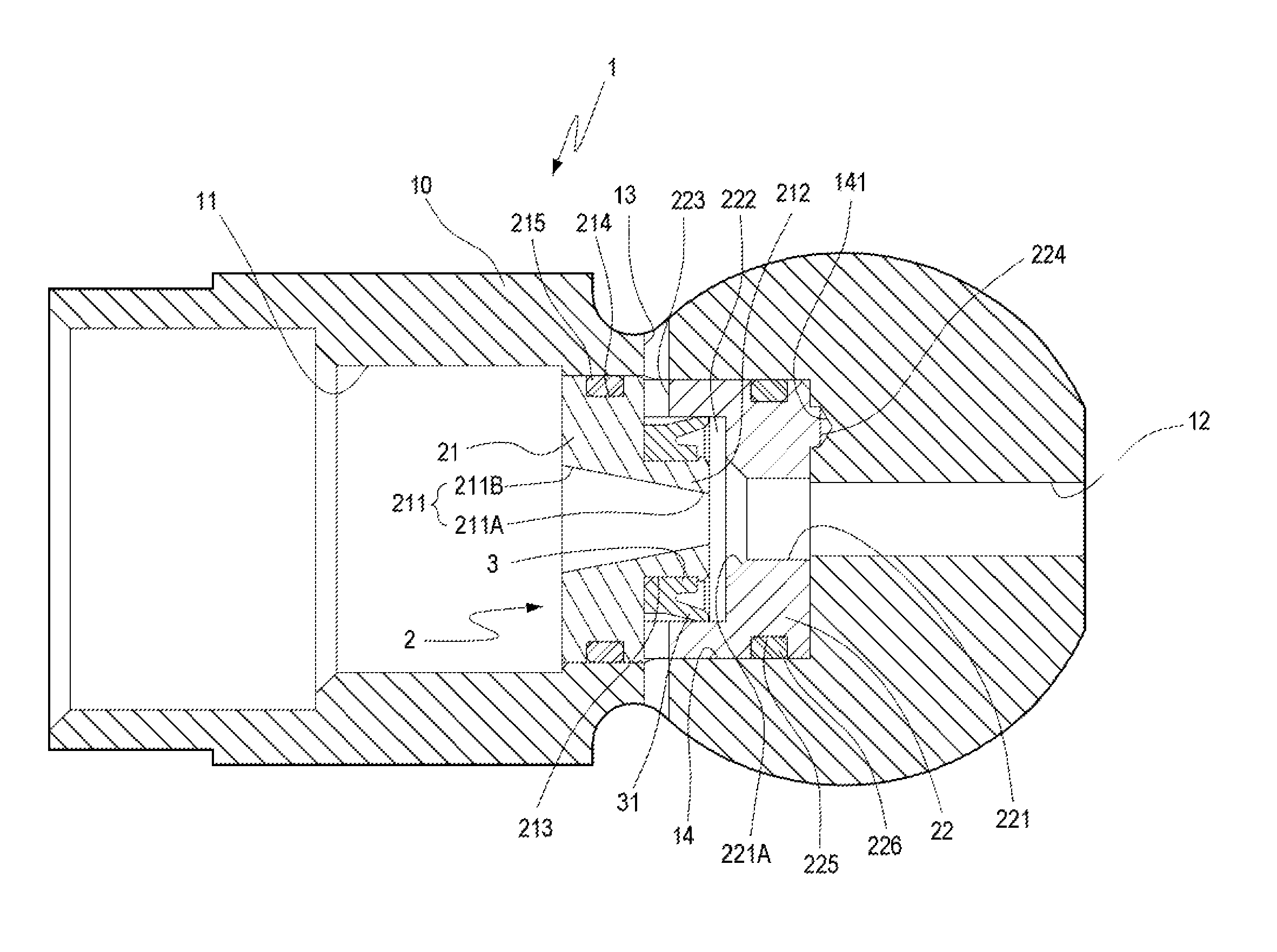

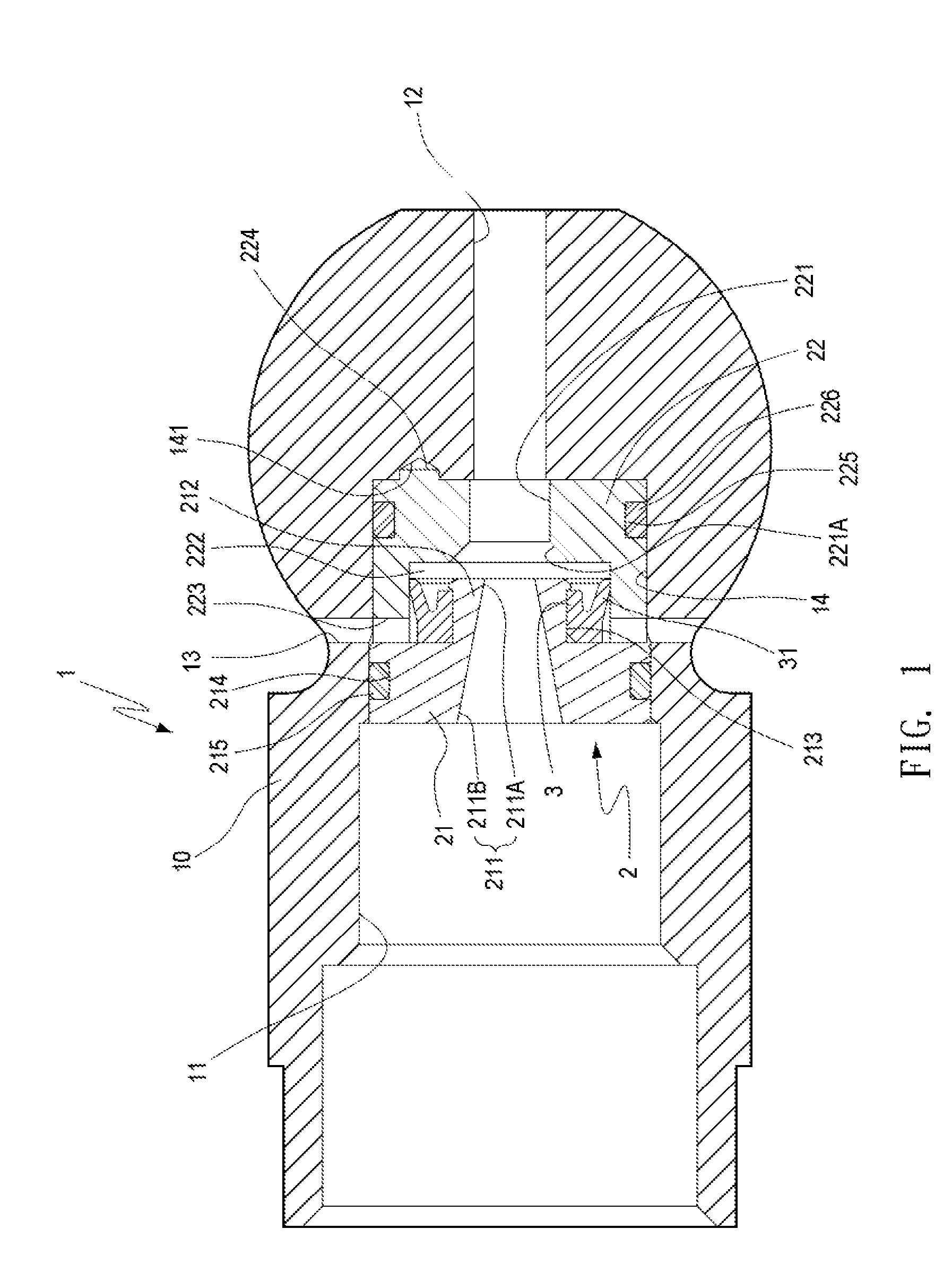

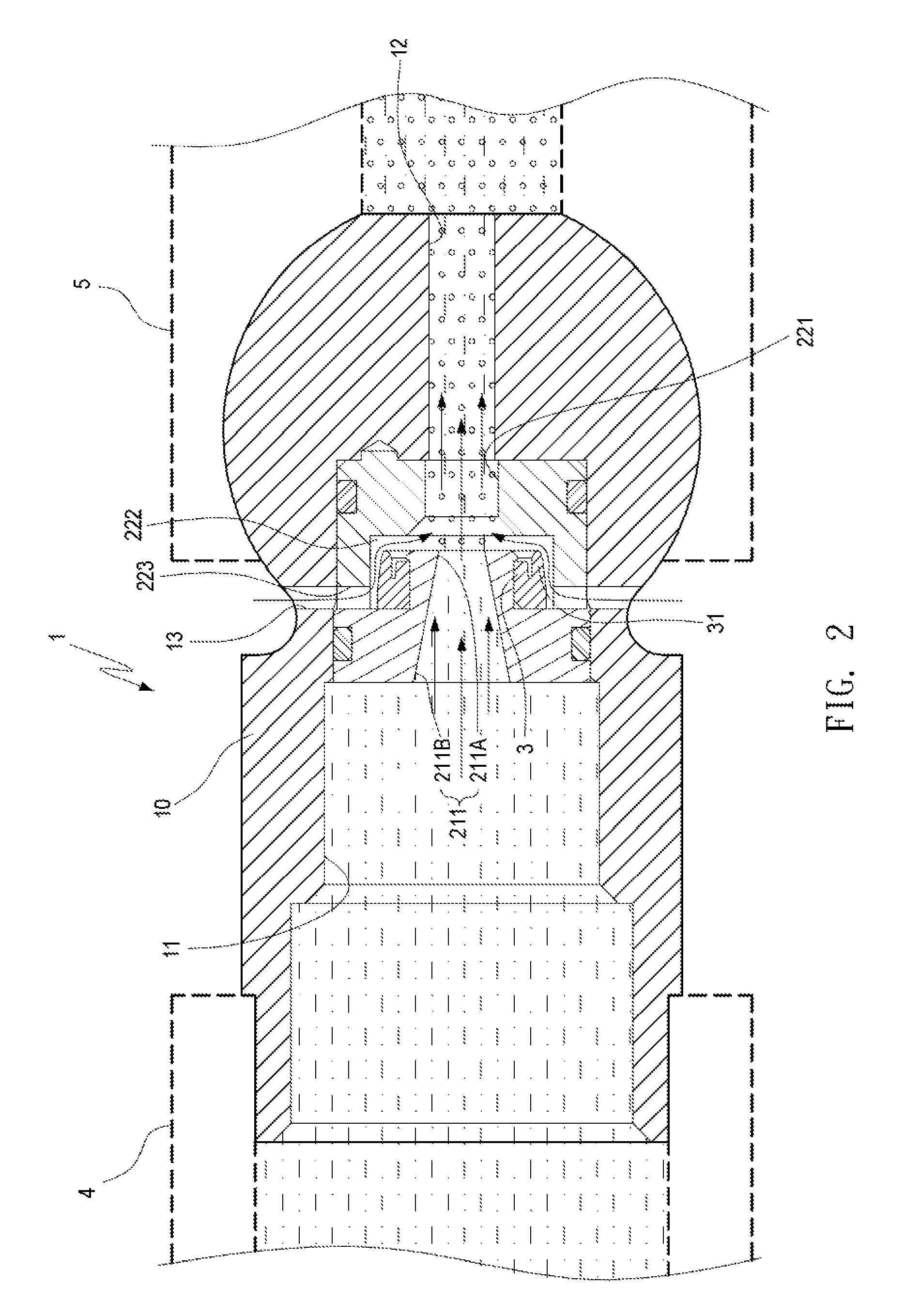

Air intake module of water feeding apparatus

InactiveUS20120080097A1Conserve waterIncrease pressureFlow mixersPressure pumpsInlet channelWater flow

An air intake module of a water feeding apparatus is provided, which includes a body and a valve, and the body includes a water inlet channel and a water outlet channel. An air intake hole runs through the body outward from a joint between the water inlet channel and the water outlet channel, and the valve is disposed at the joint. With the change of a cross-sectional area of the joint, a phenomenon of a high flow rate and a low pressure occurs to force the valve plate open, and air is sucked in mixed with the water flow. When a back pressure of the water flow is larger than an atmospheric pressure outside, the valve plate is forced to close the air intake hole, so as to avoid leakage of the water flow and prevent the air intake hole from being clogged by impurities.

Owner:GLOBE UNION INDAL

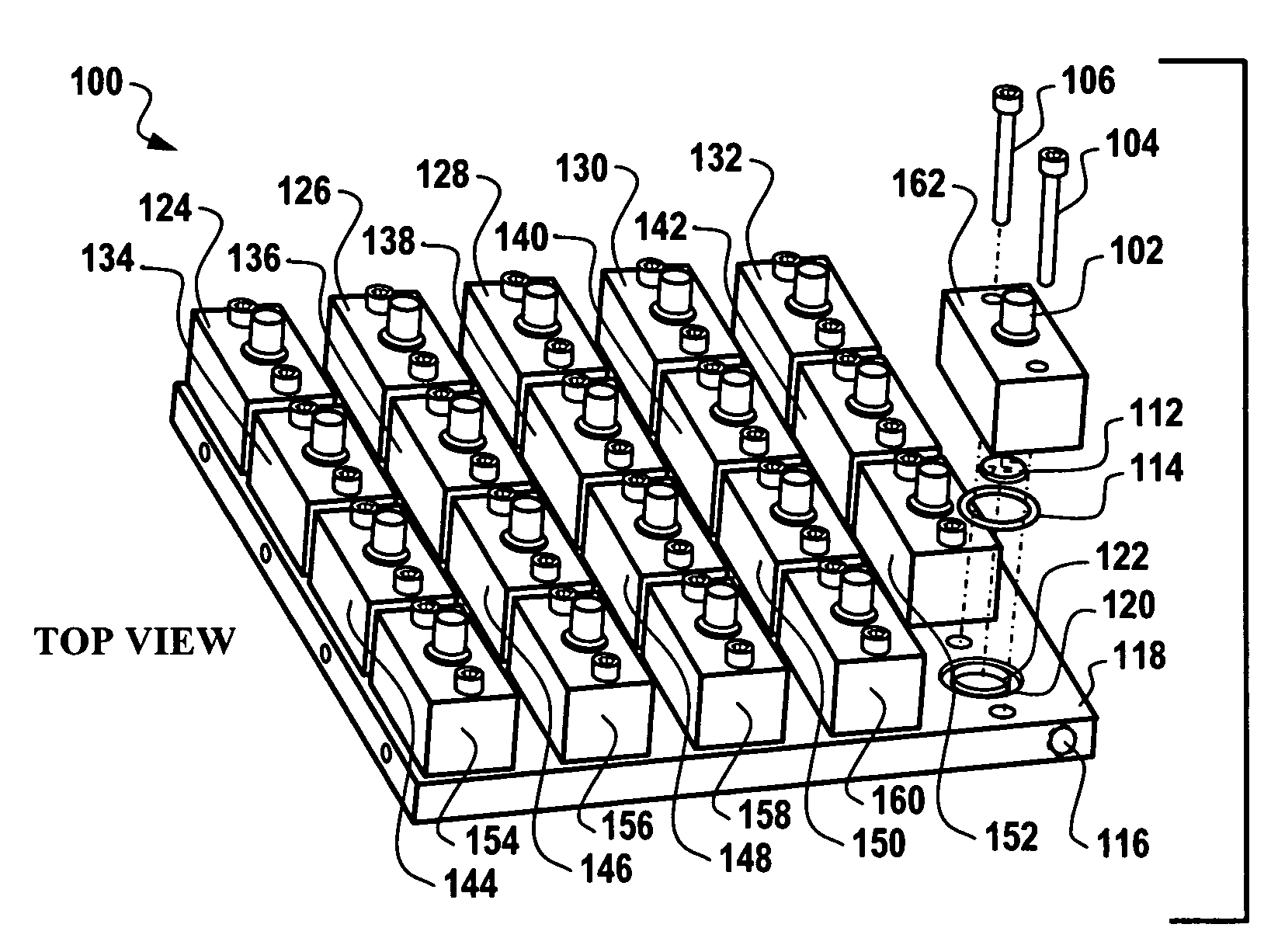

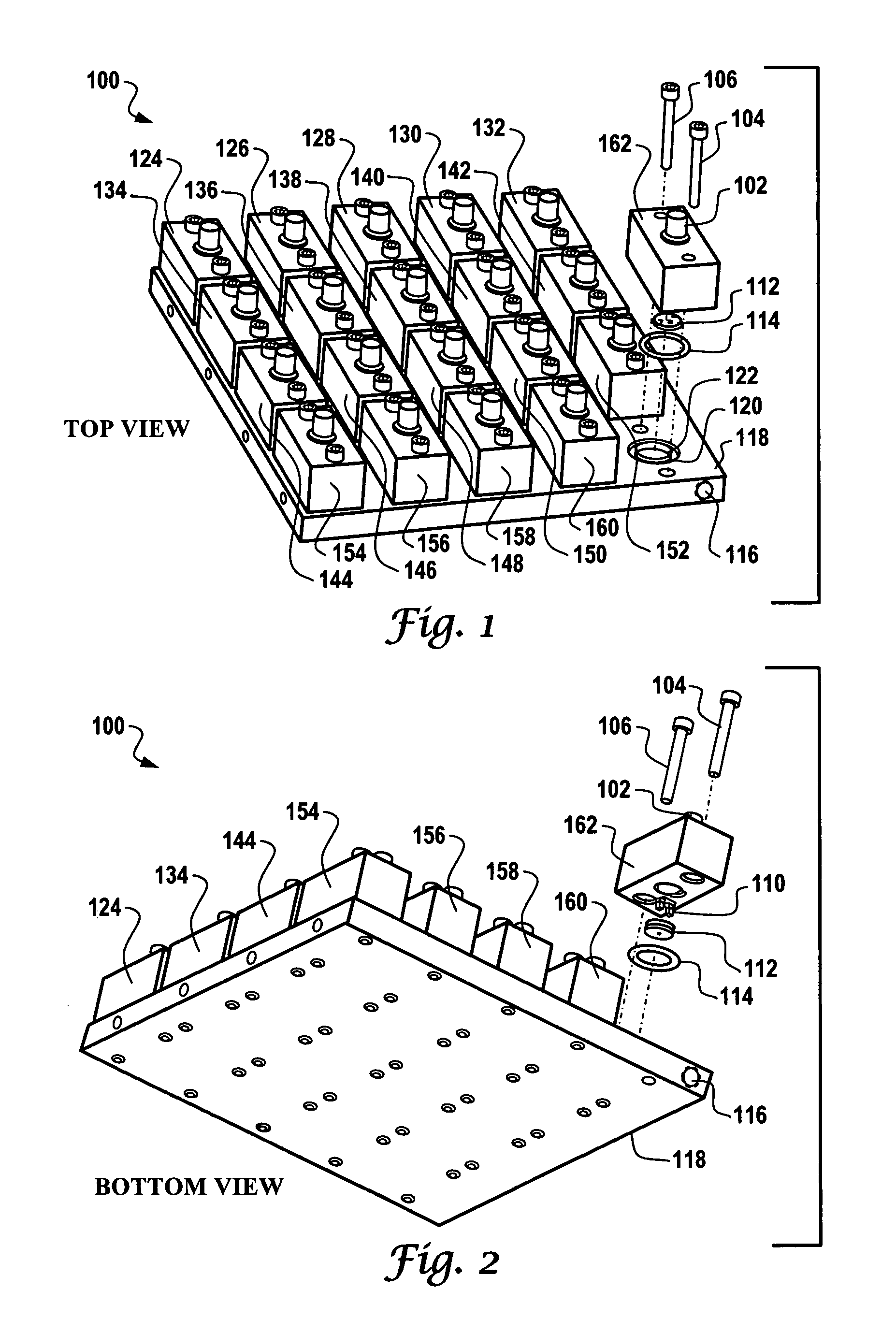

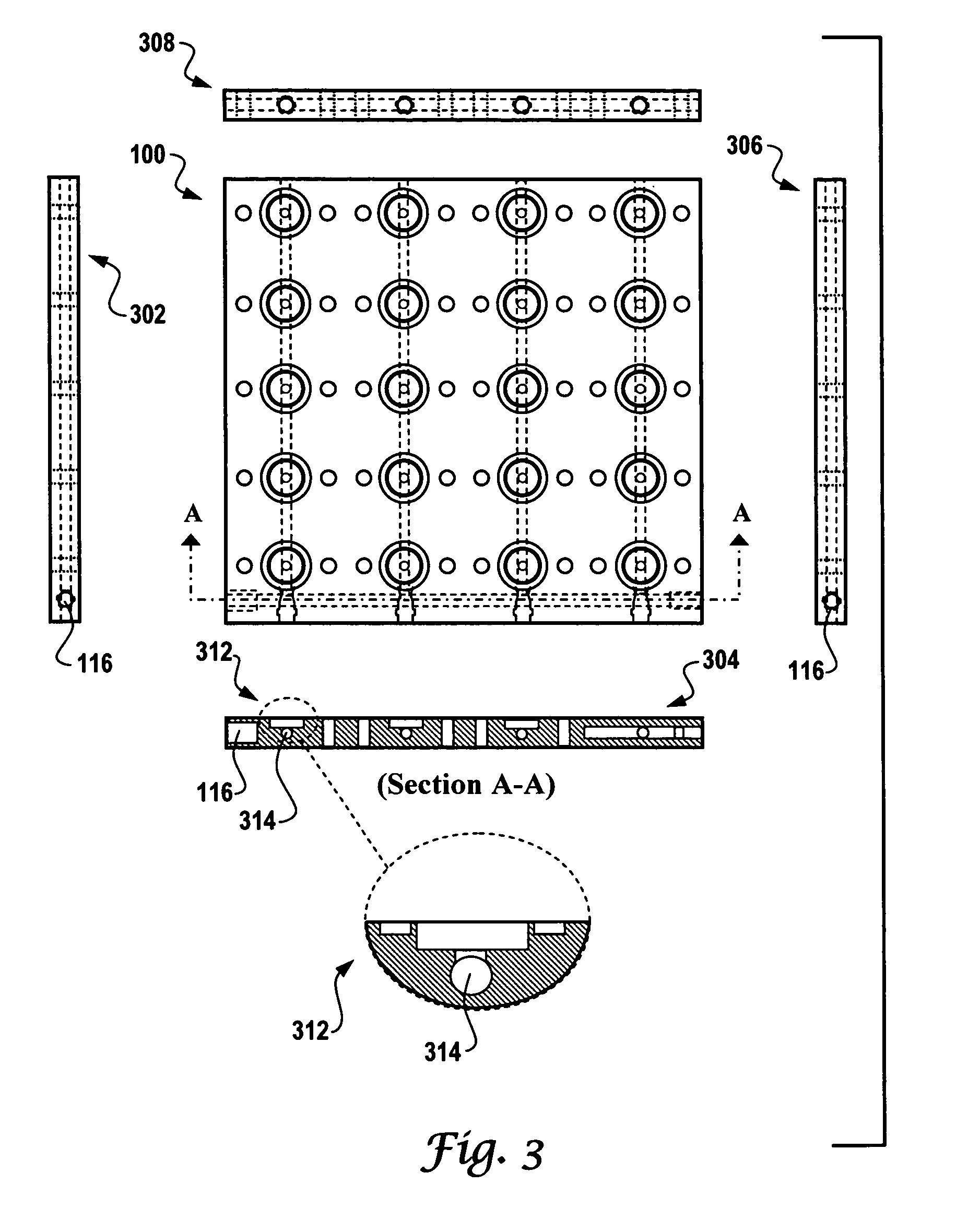

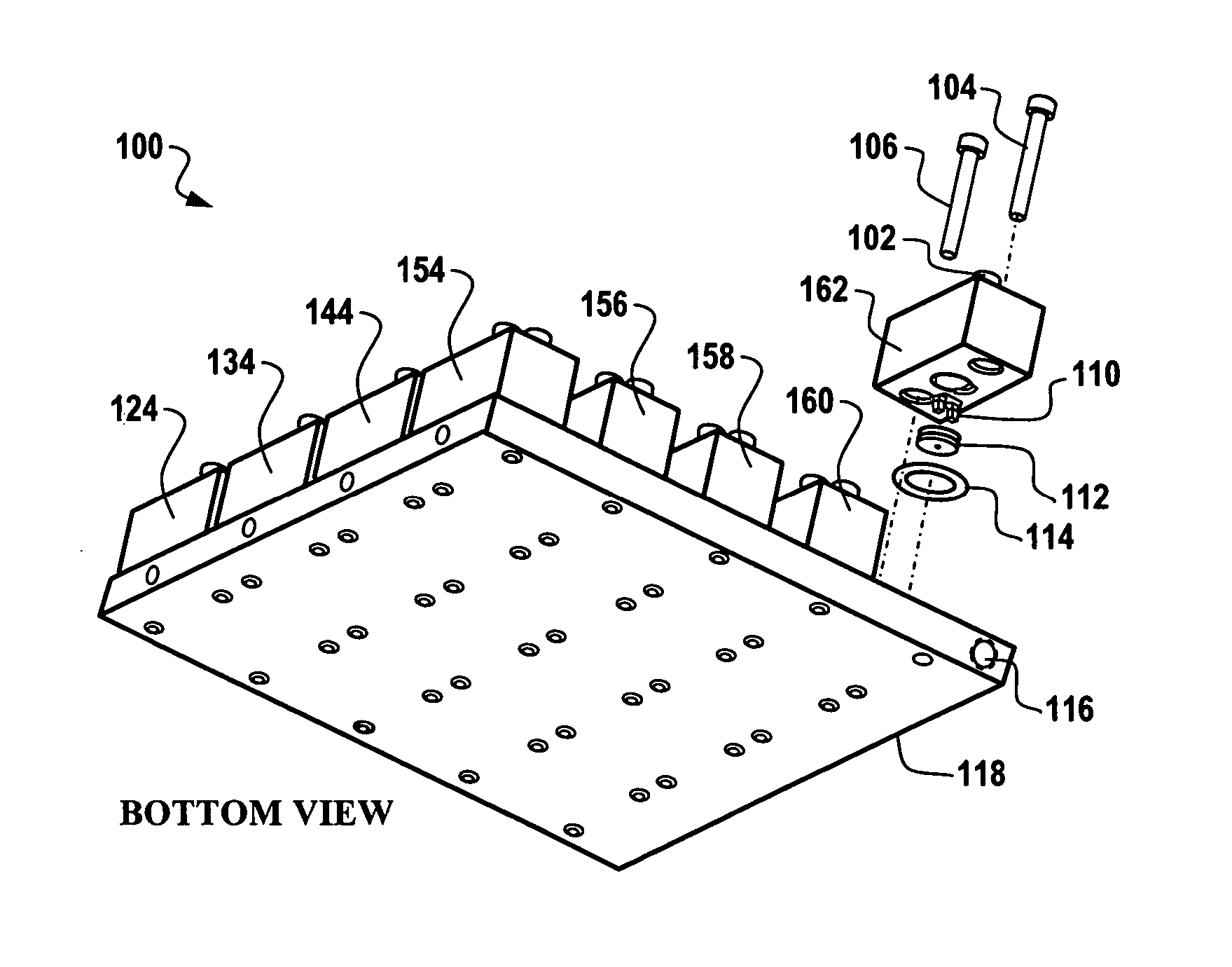

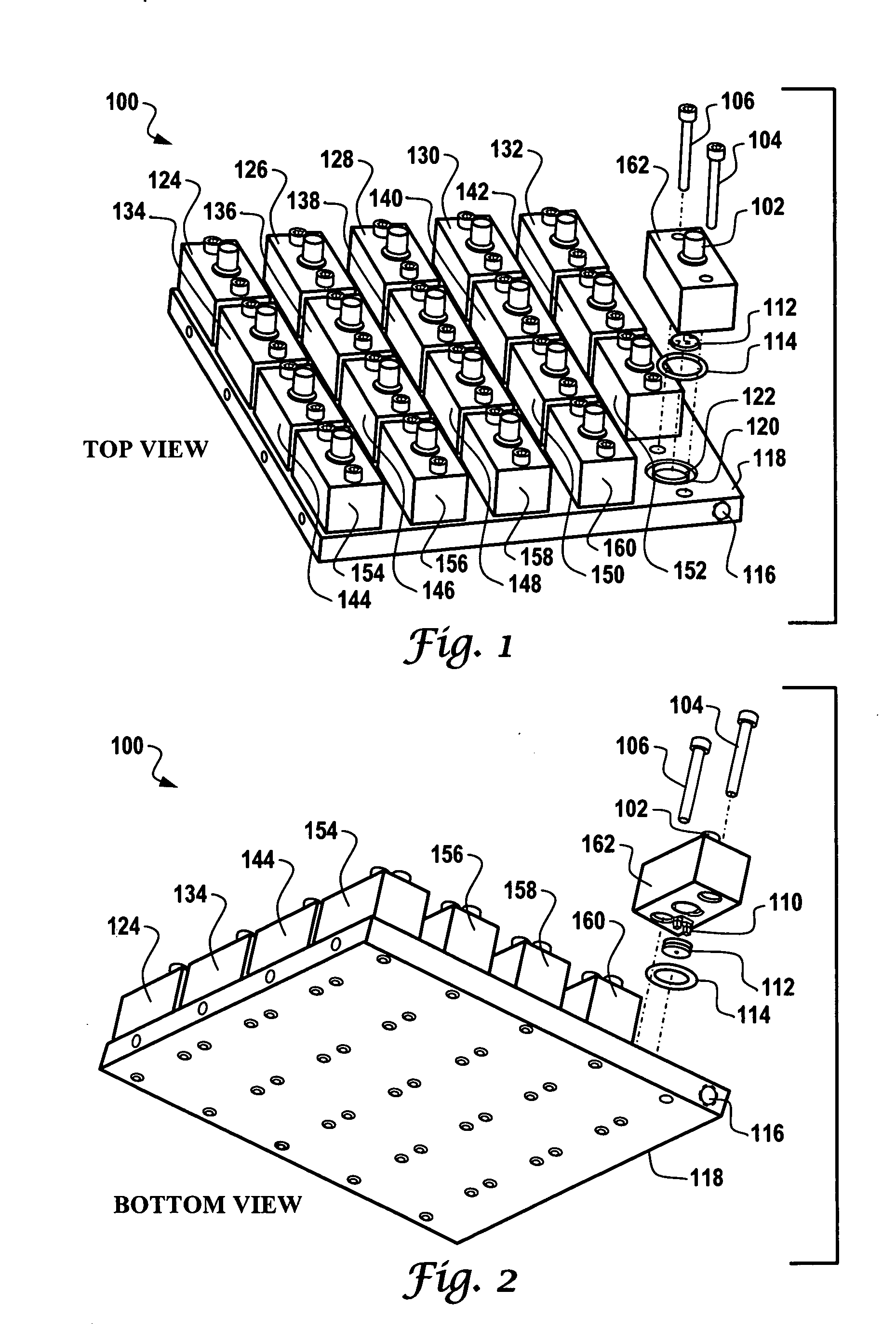

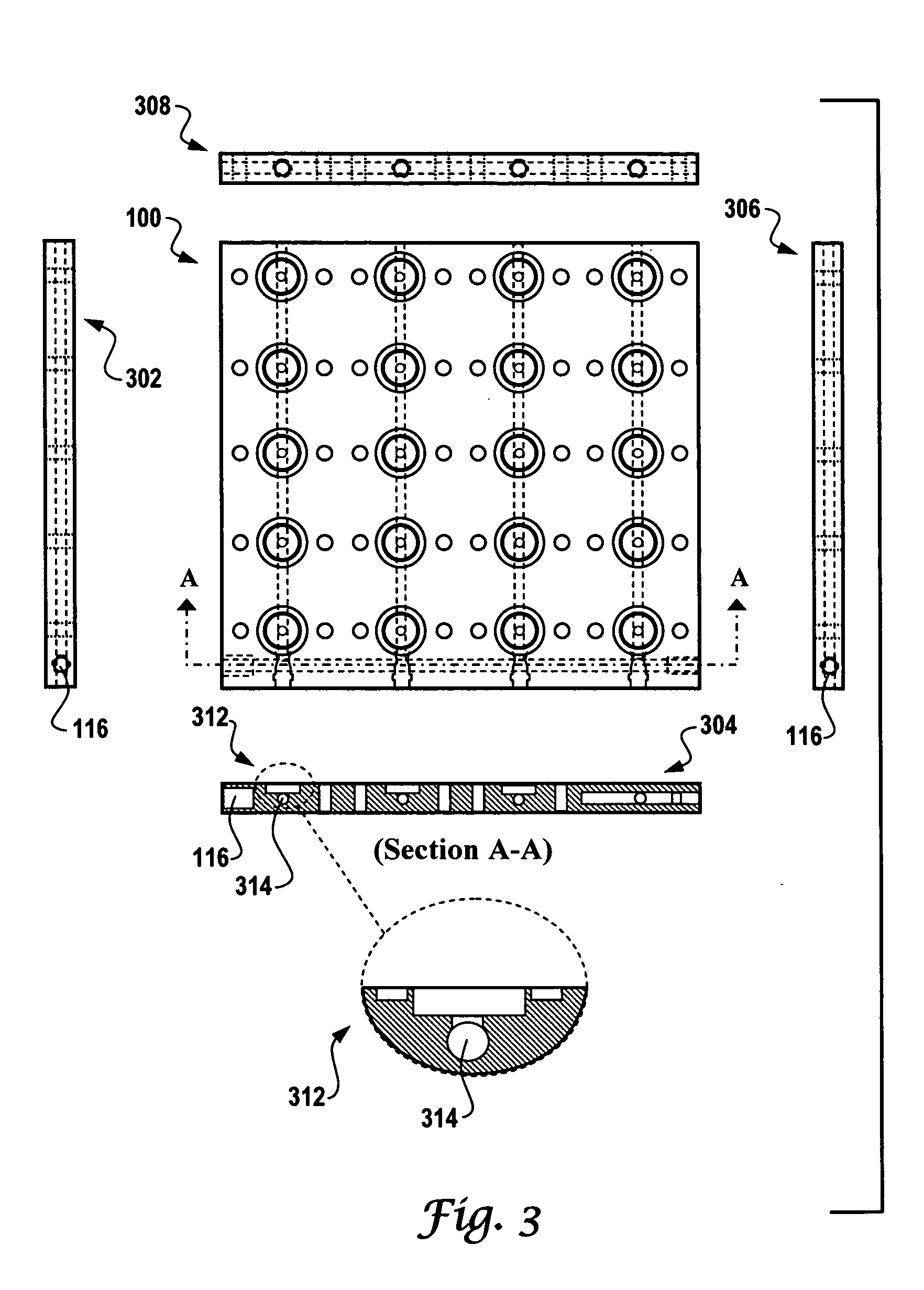

Sensor testing system and method

InactiveUS6964198B2Prevent pressure leaksFluid pressure measurement by electric/magnetic elementsPiezoelectric/electrostrictive devicesEngineeringHigh pressure

In general, a pressure rail can be provide, which includes one or more pressure inlets and a plurality of pressured cavities formed therein. Housing components can be respectively located atop the pressured cavities, such that each housing component is sealed to a respective pressurized cavity. A connector component can be threaded into the top of each housing component for attachment to a sensor (e.g., a SAW sensor) for testing thereof. Each housing component can be configured from a clear thermoplastic material, which protects the housing components from RF frequencies, and high temperature and pressure conditions.

Owner:HONEYWELL INT INC

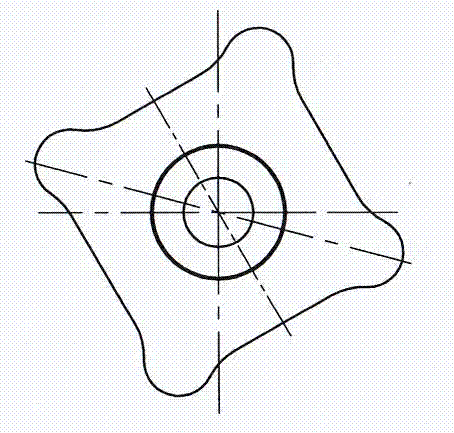

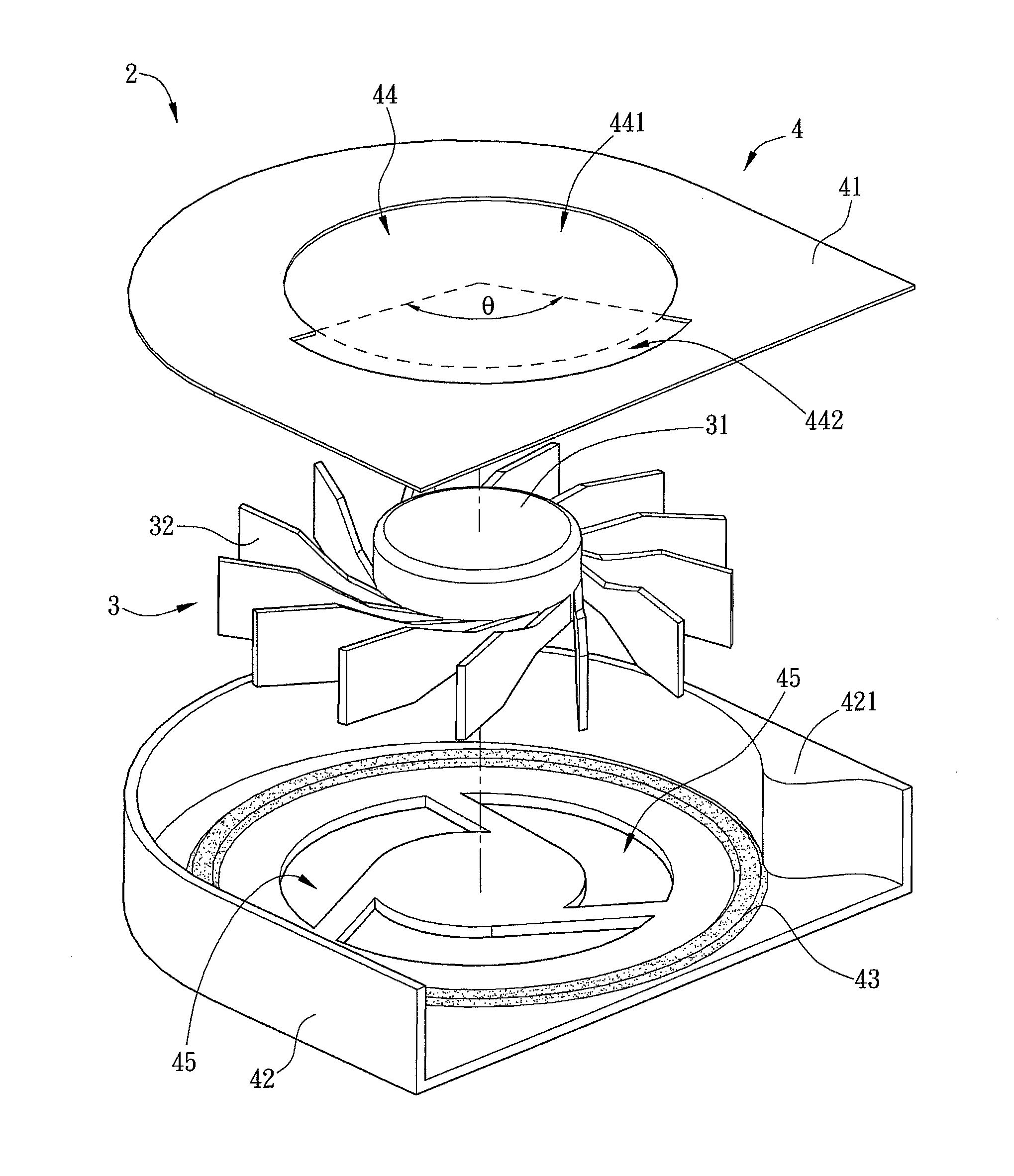

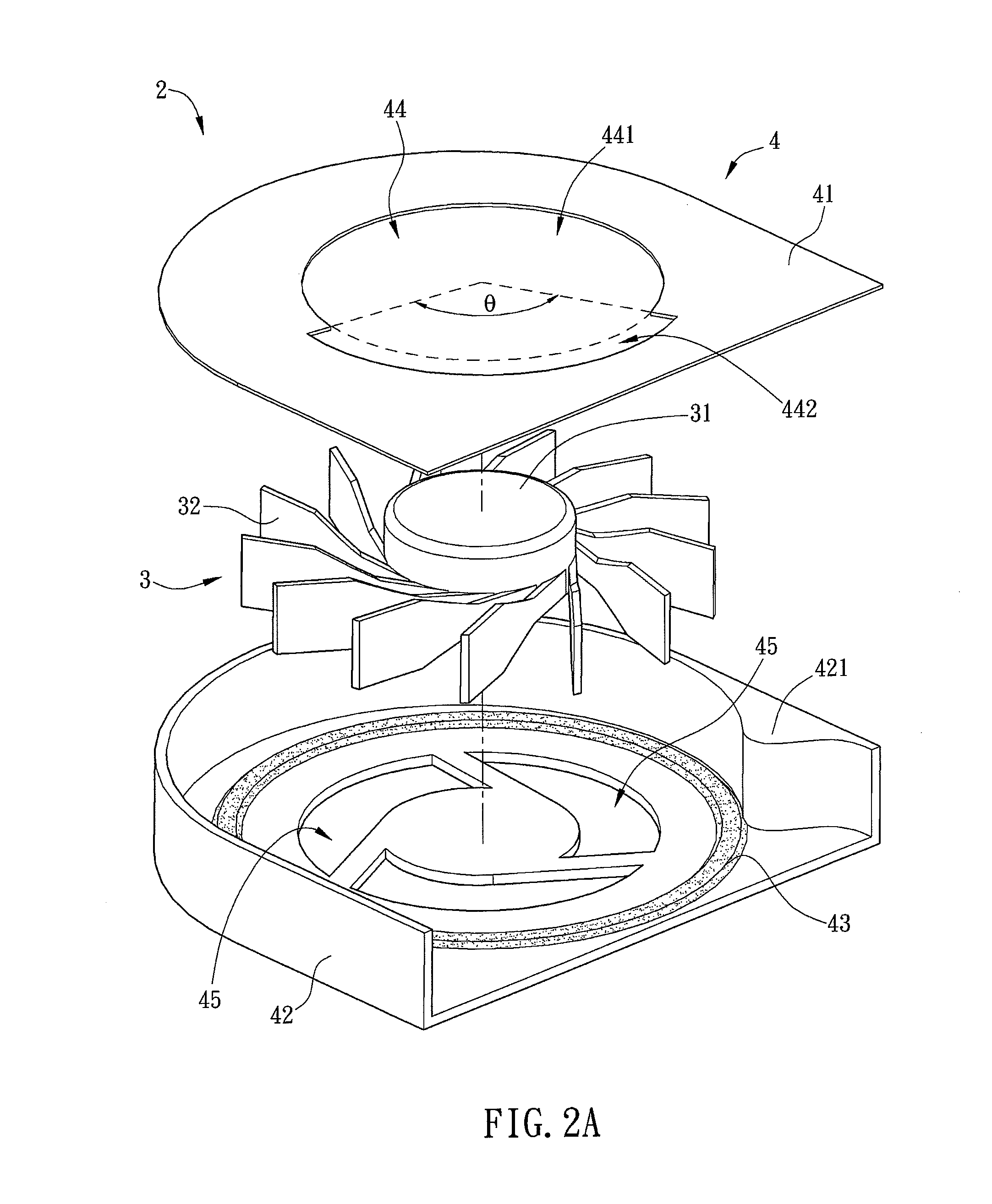

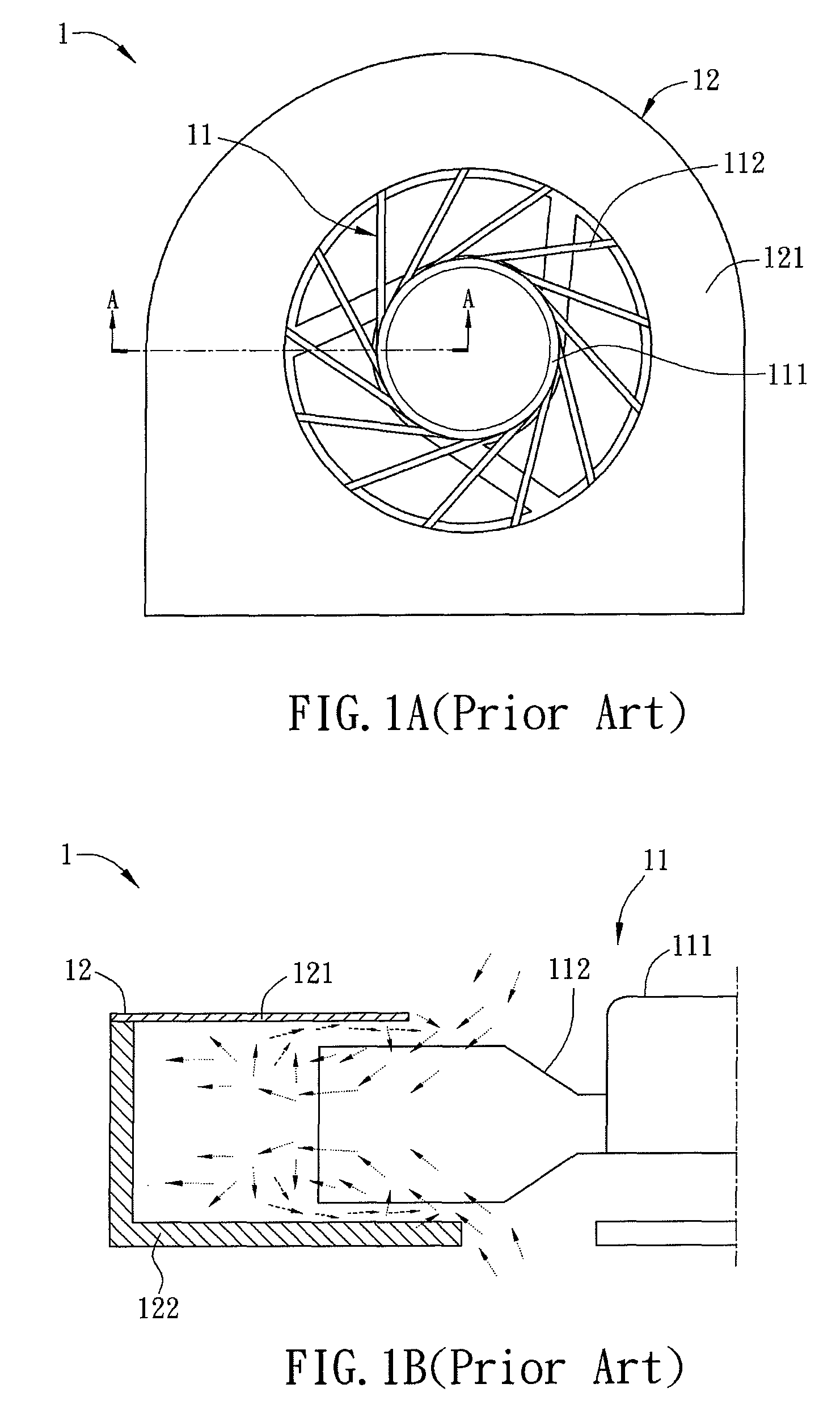

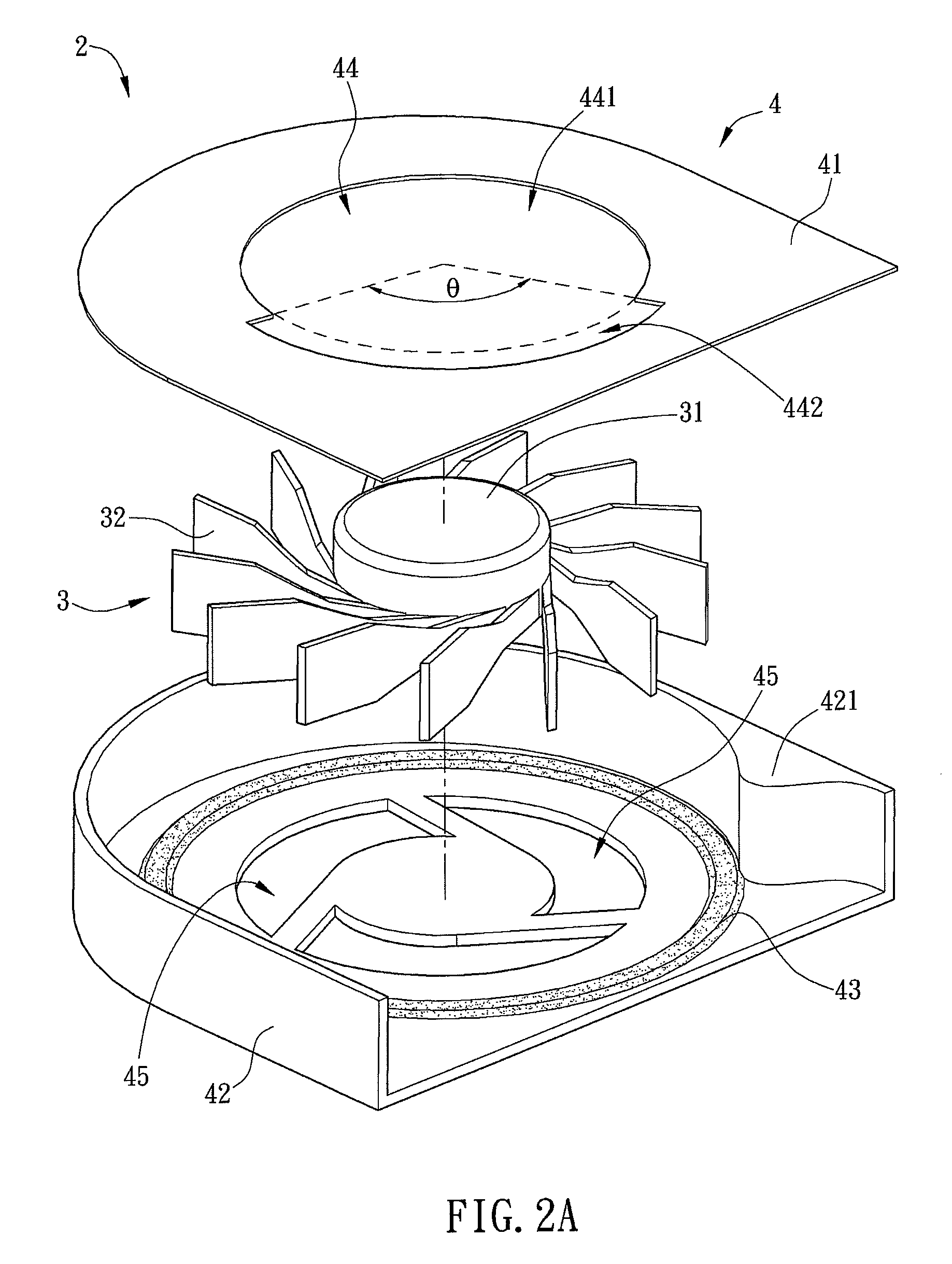

Centrifugal fan

ActiveUS20130115066A1Increase the number ofImprove performancePump componentsRotary non-positive displacement pumpsImpellerEngineering

A centrifugal fan comprises an impeller and a casing. The impeller includes a hub and a plurality of blades. The casing comprises an upper casing, a lower casing, at least one protrusion, a first inlet opening and a second inlet opening. The lower casing is disposed opposite to the upper casing and connected to the upper casing to form an accommodation room for receiving the impeller. The protrusion is formed on the upper casing and / or the lower casing inside the casing and immediately surrounds the blades. The first inlet opening is defined on the upper casing and comprises a primary inlet opening augmented by a secondary inlet opening. The second inlet opening is defined on the lower casing. The protrusion surrounds the first inlet opening and / or second inlet opening.

Owner:DELTA ELECTRONICS INC

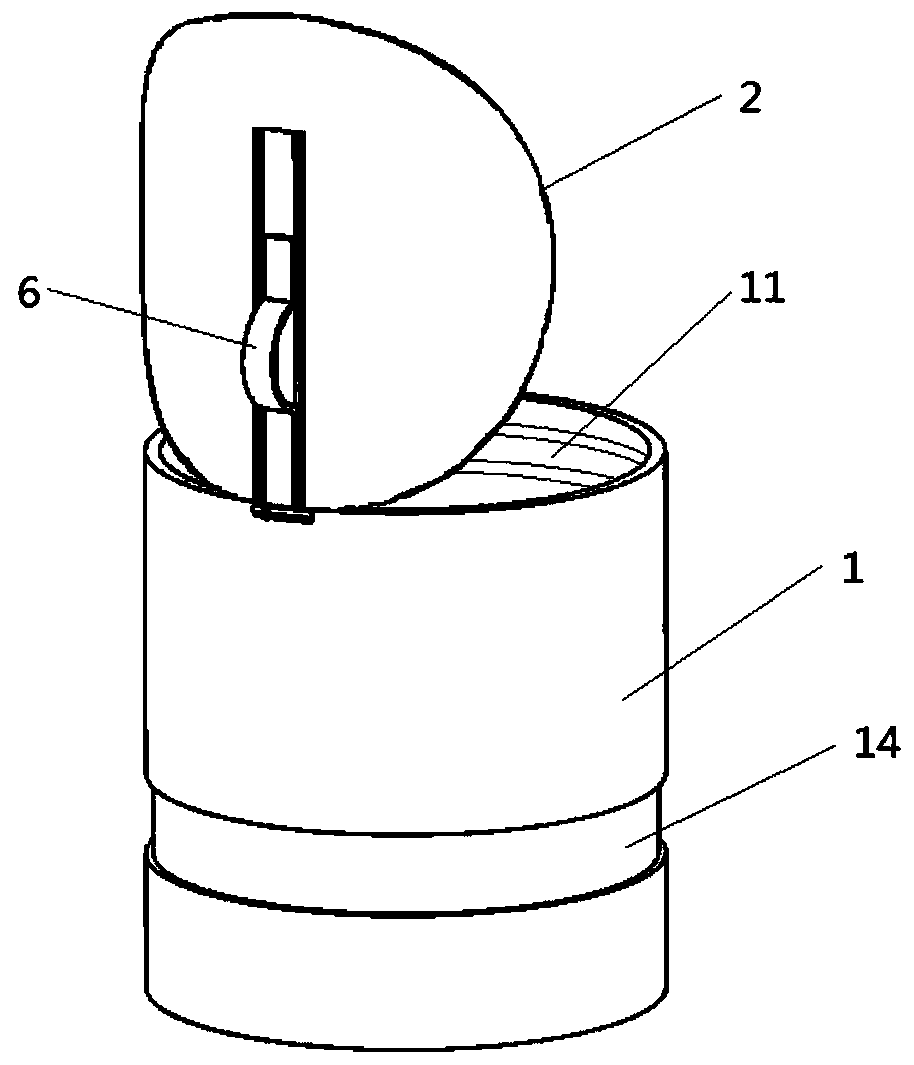

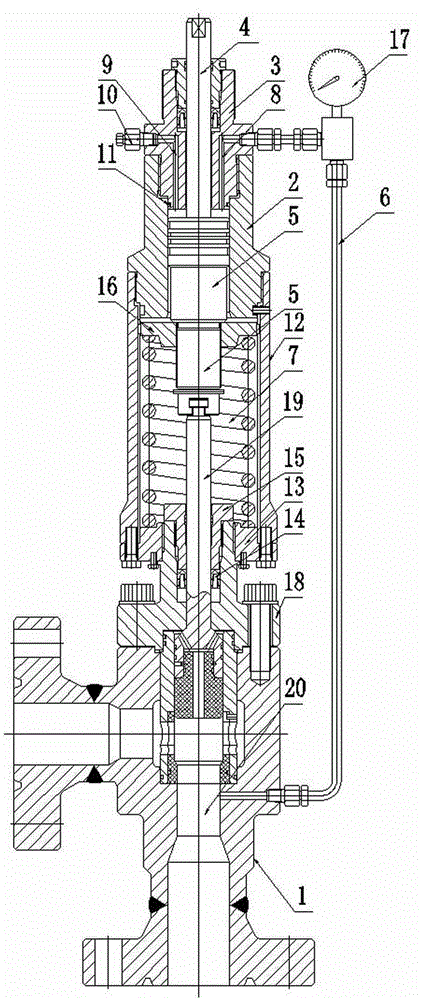

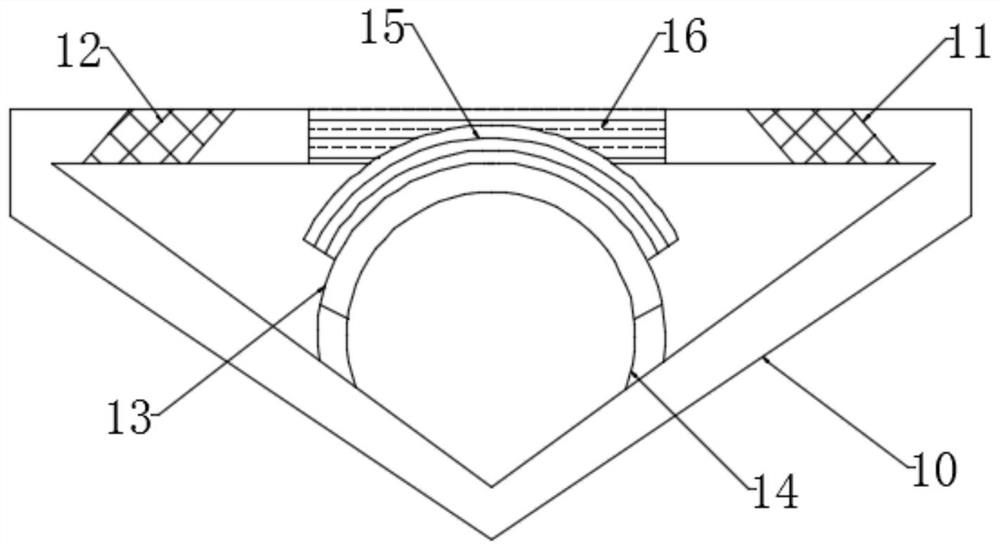

Pressure-maintaining core sampler flap valve with multi-stage sealing structure

The invention relates to a pressure-maintaining core sampler flap valve with a multi-stage sealing structure. The pressure-maintaining core sampler flap valve comprises a valve seat and a valve clack;one end of the valve clack is movably connected with the upper end of the valve seat; a valve opening which is matched with the valve clack is formed in the top of the valve seat, and when the valveclack is closed, at least two sealing pairs are formed between the valve seat and the valve clack; sealing between the valve seat and the valve clack includes hard sealing and soft sealing; at least two sealing parts are arranged in the valve opening of the valve seat; the first sealing part comprises a metal sealing ring and a U-shaped sealing structure; and when the valve clack is closed, the valve clack and the metal sealing ring are in contact to form hard sealing, and meanwhile the valve clack makes the metal sealing ring expand so as to squeeze the U-shaped sealing structure to form softsealing. The valve seat and the valve clack adopt the multi-stage sealing structure, the sealing property is reliable, multi-line / plane sealing contact is achieved, and thus valve leakage can be effectively prevented; the deformation resistance of an airtight surface can be effectively improved through the expandable property of the metal sealing ring, during pressing, deformation of the pressedvalve clack and valve seat can be compensated, pressure leakage is avoided, and the pressure-maintaining core sampler flap valve is applicable to the high-temperature and high-pressure working conditions.

Owner:SHENZHEN UNIV

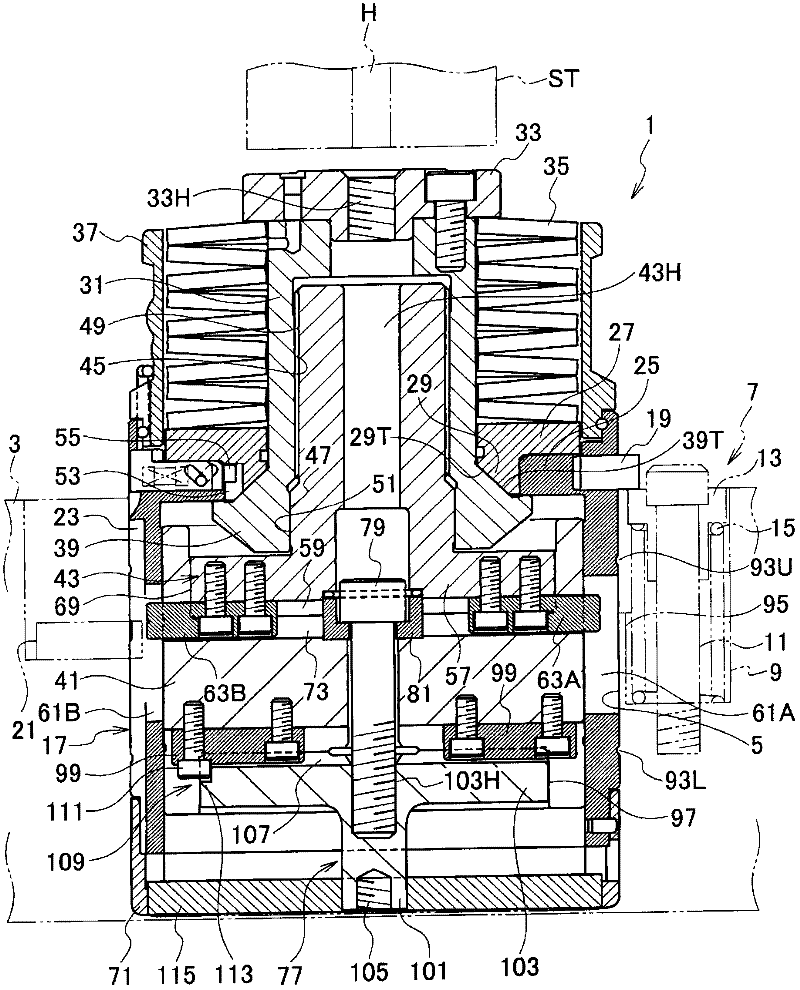

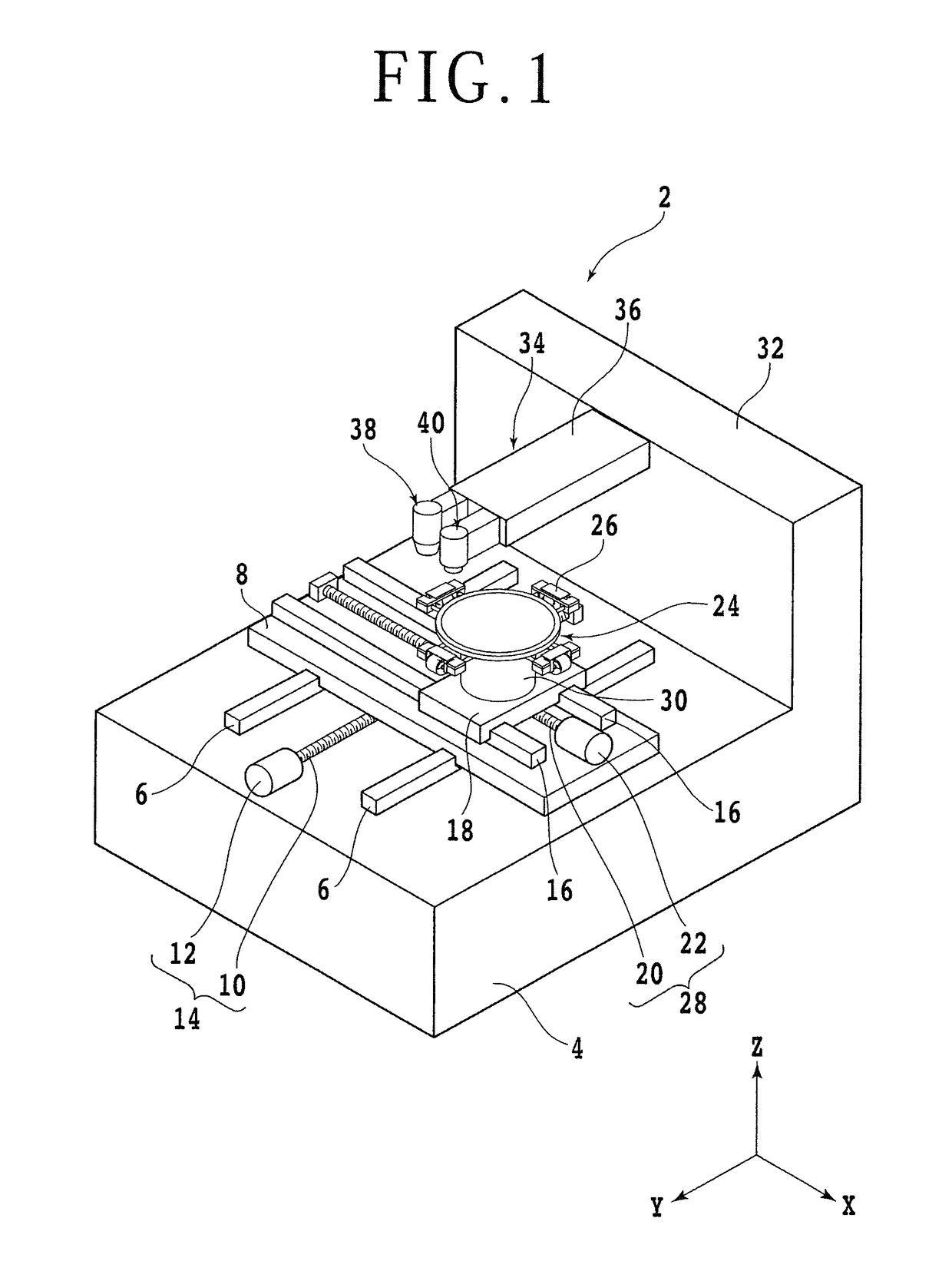

Punch die and method of supplying lubricating oil

InactiveCN102395435APrevent pressure leaksImprove the lubrication effectShaping toolsPerforating toolsPunch pressEngineering

A punch die which is vertically movably mounted to a punch mounting hole (5) formed in a punch holder (3) of a punch press, wherein a punch body (41) which has a punch edge section (101) at the lower end thereof is vertically movably provided within a tubular punch guide (17) which is vertically movably mounted within the punch mounting hole (5), an elastic member (35) is provided between the punch guide (17) and a punch head (33) at the upper end of a punch driver (31) provided to the upper part of the punch body (41), a supported section (19) which is supported by a lifter spring (7) provided to the punch holder (3) is provided to the outer peripheral surface of the punch guide (7), a lubricating oil path (93U) which communicates with a lubricating oil supply path (83) formed in the punch body (41) is provided to the outer peripheral surface of the punch guide (17), and the lubricating oil path (93U) can be communicated with and interrupted from a lifter spring containing hole (9) which contains the lifter spring (7).

Owner:AMADA CO LTD

Sensor testing system and method

InactiveUS20050183509A1Prevent pressure leaksFluid pressure measurement by electric/magnetic elementsEngineeringHigh pressure

In general, a pressure rail can be provide, which includes one or more pressure inlets and a plurality of pressured cavities formed therein. Housing components can be respectively located atop the pressured cavities, such that each housing component is sealed to a respective pressurized cavity. A connector component can be threaded into the top of each housing component for attachment to a sensor (e.g., a SAW sensor) for testing thereof. Each housing component can be configured from a clear thermoplastic material, which protects the housing components from RF frequencies, and high temperature and pressure conditions.

Owner:HONEYWELL INT INC

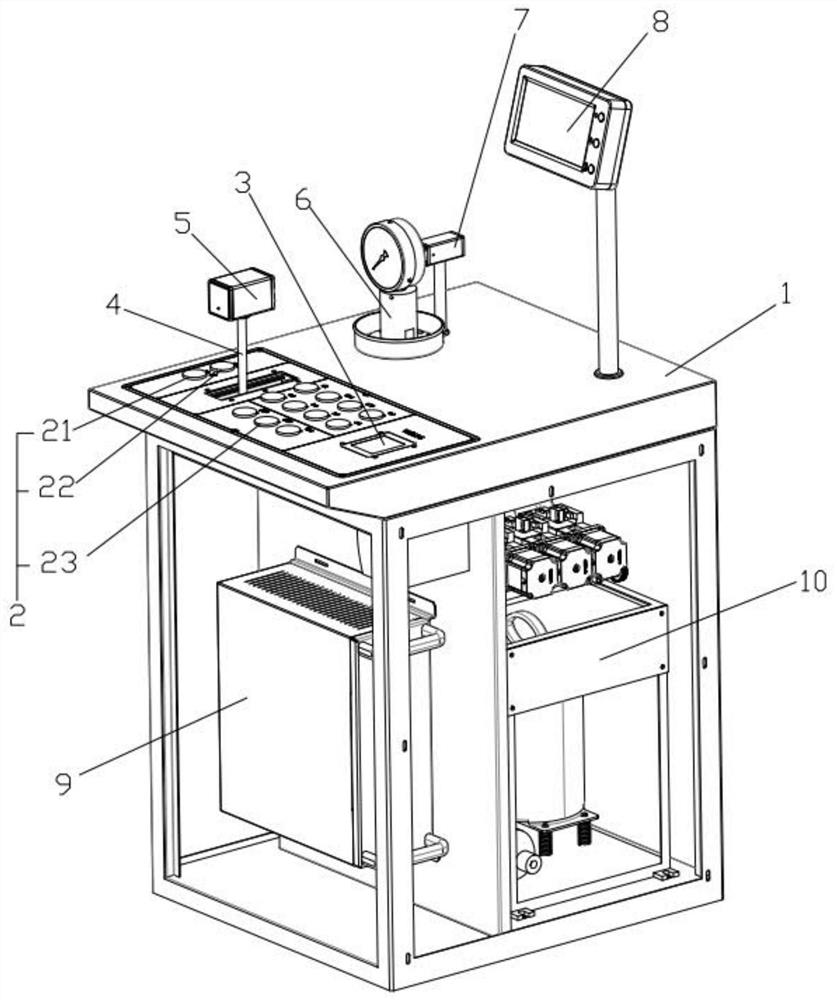

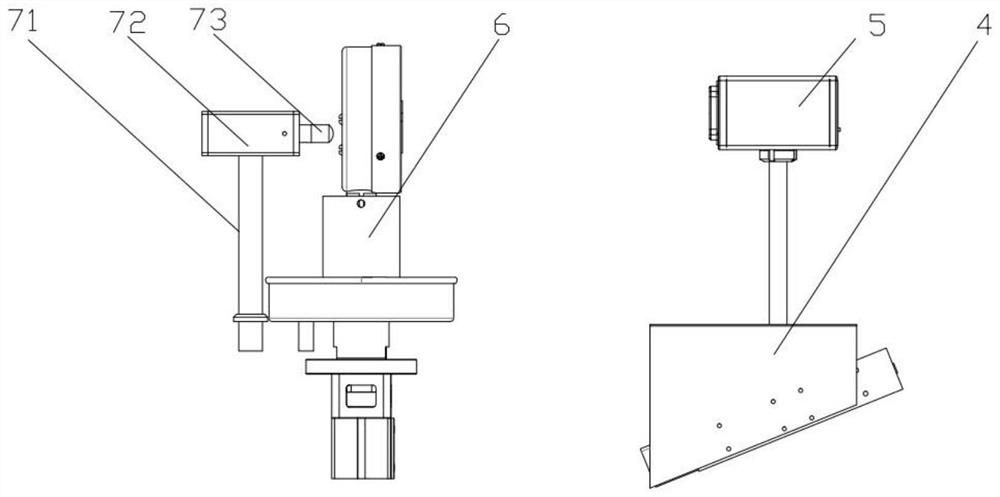

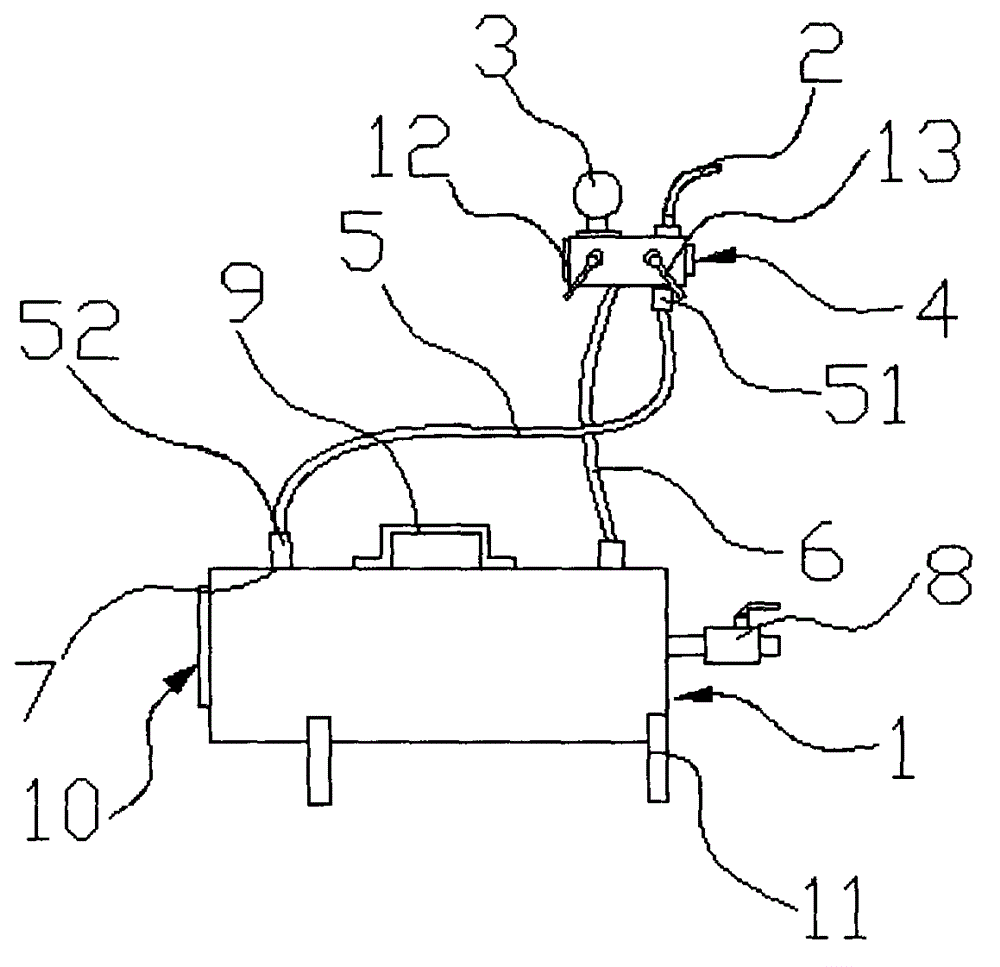

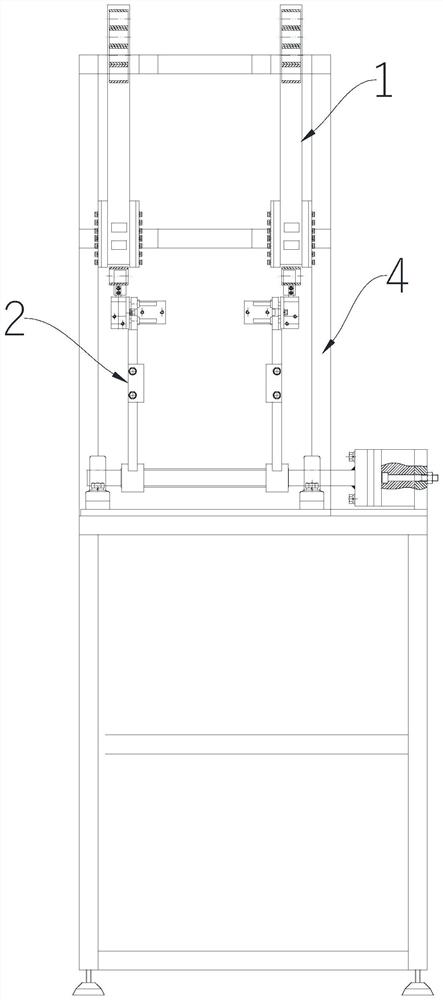

Full-automatic pressure gauge verification table and full-automatic verification method

PendingCN112197902ARealize automated detectionImprove intelligenceFluid pressure measurementControl systemControl engineering

The invention relates to improvement of a pressure gauge verification technology, in particular to a full-automatic pressure gauge verification table and a full-automatic verification method; and thefull-automatic pressure gauge verification table comprises a verification table, a switch, a code scanning device, a camera adjusting mechanism, a camera, a gauge clamping mechanism, a gauge knockingmechanism, a display, a controller and a gas circuit control system; the camera adjusting mechanism comprises a sliding base and a sliding block, the sliding block is in sliding fit with the sliding base, the sliding base is inclined, the camera is installed on the sliding block and faces the gauge clamping mechanism, the gauge knocking mechanism comprises a vertical rod, a telescopic air cylinderand a push rod, the push rod is connected with a telescopic end of the telescopic air cylinder, and a cylinder body of the telescopic air cylinder is installed on the vertical rod. The full-automaticpressure gauge verification table has the advantages of less manual intervention, high automation integration level and high detection accuracy, and can realize the automatic pressure gauge detectionfunction of scanning once, knocking for three times and easily detecting the pressure gauge.

Owner:江苏丰仪同创互联科技有限公司

Centrifugal fan

ActiveUS9206813B2Increase the number ofImprove performancePump componentsRotary non-positive displacement pumpsImpellerEngineering

A centrifugal fan comprises an impeller and a casing. The impeller includes a hub and a plurality of blades. The casing comprises an upper casing, a lower casing, at least one protrusion, a first inlet opening and a second inlet opening. The lower casing is disposed opposite to the upper casing and connected to the upper casing to form an accommodation room for receiving the impeller. The protrusion is formed on the upper casing and / or the lower casing inside the casing and immediately surrounds the blades. The first inlet opening is defined on the upper casing and comprises a primary inlet opening augmented by a secondary inlet opening. The second inlet opening is defined on the lower casing. The protrusion surrounds the first inlet opening and / or second inlet opening.

Owner:DELTA ELECTRONICS INC

Rotary compressor

InactiveCN101684798APrevent pressure leaksAvoid deformationRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringHigh pressure

The invention provides a rotary compressor, comprising a housing; a cylinder with a compression chamber and a blade groove, wherein the blade groove is composed of, a blade guide part formed by makingan outward depression of the inner wall of the compression chamber, and an enclosed chamber arranged outside the blade guide part and having a width that is more than that of the blade guide part bya predetermined expansion width; blades capable of moving forwards and backwards along the blade groove and simultaneously partitioning the compression chamber; a flange part for sealing the upper andlower openings of the cylinder; and a communication part, which passes through the outer side surface of the cylinder and extends to the enclosed chamber along the direction different from the movingdirection of the blades, for providing high pressure or low pressure for the enclosed chamber. Thus, the rotary compressor of the invention can enable the deformation of the parts to be minimized, thereby preventing the pressure leakage of the compression chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

Automatic-control constant-pressure throttling valve

InactiveCN104879543AReduce trafficConstant pressureOperating means/releasing devices for valvesEqualizing valvesAutomatic controlCylinder block

The invention discloses an automatic-control constant-pressure throttling valve. The automatic-control constant-pressure throttling valve comprises a valve body and an execution mechanism. The execution mechanism comprises a cylinder body, a cylinder cover, a piston, a pressure tapping pipe and an elastic element. The cylinder body is fixedly arranged above the valve body, the cylinder cover is fixed to the upper portion of the cylinder body, the piston is movably arranged in the cylinder body, the lower portion of the piston is fixed onto a valve rod of the valve body, and the elastic element is fixedly arranged between the cylinder body and the valve body and fixedly connected with the piston. A pressure tapping end of the pressure tapping pipe is communicated with an output end of the valve body, and a pressure discharging end of the pressure tapping pipe is arranged above the piston in the cylinder body. The automatic-control constant-pressure throttling valve has the advantages that flow output of the throttling valve can be automatically controlled under the action of pipeline pressure, and the problem that a safety valve in the prior art is prone to jumping automatically under overhigh pressure is solved.

Owner:德阳正光石油机械制造有限公司

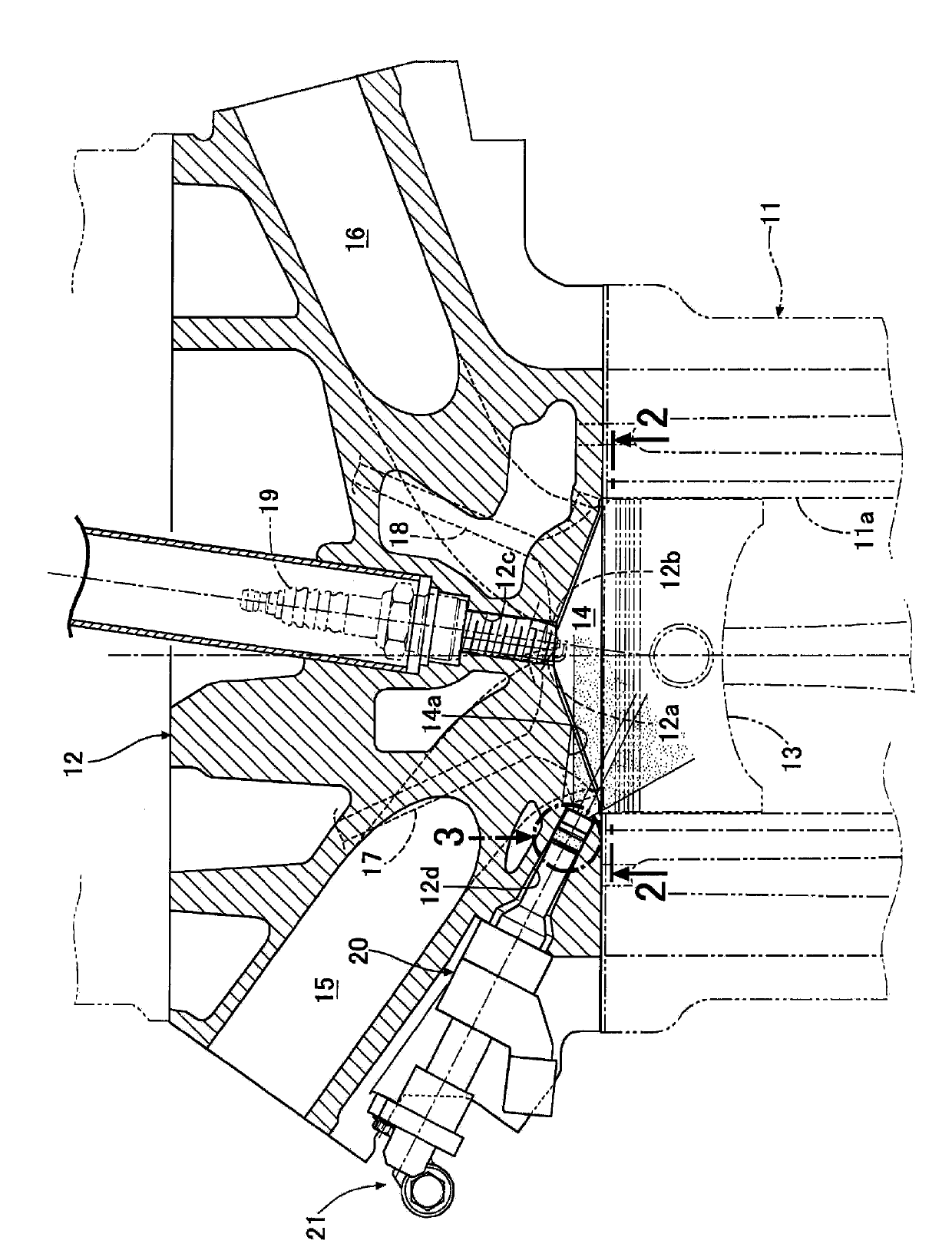

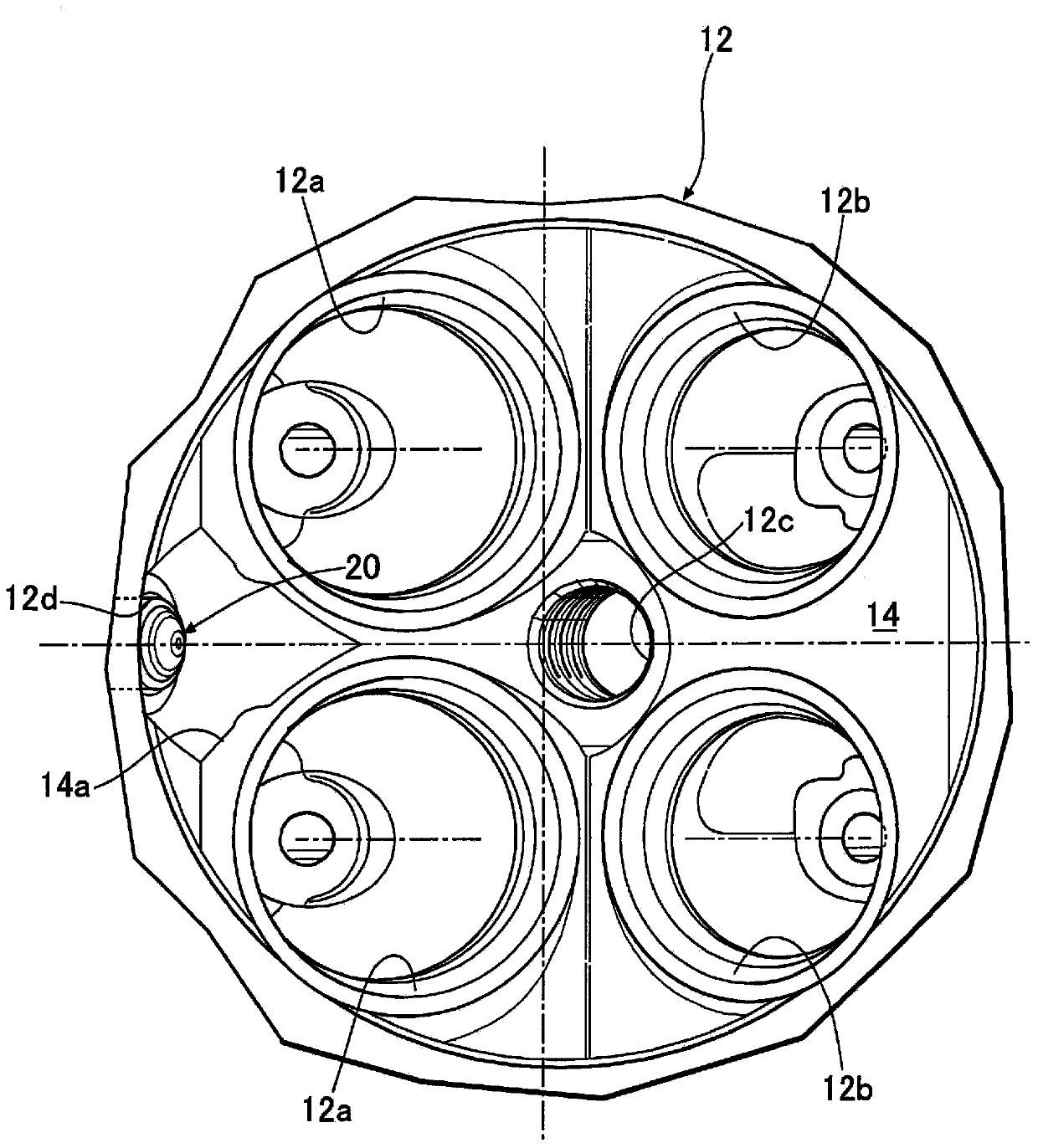

In-cylinder pressure detecting device of direct injection type internal combustion engine

ActiveCN103380357AAvoid interferenceInhibit overheatingElectrical controlInternal combustion piston enginesCombustion chamberCylinder head

In an in-cylinder pressure detecting device of a fuel direct injection type internal combustion engine, an annular pressure detecting element (34) is installed around a fuel injection hole (33b) at a position close to the tip end of an injector used to inject fuel into a combustion chamber. Since the pressure detecting element (34) is installed on the injector, it is not necessary to change the shape or structure of a cylinder head or the combustion chamber for installing the pressure detecting element (34), and since the pressure detecting element (34) can be cooled by fuel passing through the injector, the pressure detecting precision and durability of the pressure detecting element (34) can be improved. In addition, since the pressure detecting element (34) is disposed around the fuel injection hole (33b), the size of the pressure detecting element (34) can be maximally increased while preventing interference between the pressure detecting element (34) and fuel injected through the fuel injection hole (33b), so as to guarantee pressure detecting precision.

Owner:HONDA MOTOR CO LTD +1

Air intake module of water feeding apparatus

An air intake module of a water feeding apparatus is provided, which includes a body and a valve, and the body includes a water inlet channel and a water outlet channel. An air intake hole runs through the body outward from a joint between the water inlet channel and the water outlet channel, and the valve is disposed at the joint. With the change of a cross-sectional area of the joint, a phenomenon of a high flow rate and a low pressure occurs to force the valve plate open, and air is sucked in mixed with the water flow. When a back pressure of the water flow is larger than an atmospheric pressure outside, the valve plate is forced to close the air intake hole, so as to avoid leakage of the water flow and prevent the air intake hole from being clogged by impurities.

Owner:GLOBE UNION INDAL

Gas pressure detector

InactiveCN103939090ASeparate in timeEffective and adequate separationSurveyFluid removalConfined waterEngineering

Provided is a gas pressure detector. The gas pressure detector comprises a water-gas separation tank, a gas pipe and a gas pressure meter. The water-gas separation tank is provided with a water inlet and a water drainage sluice valve. The gas pressure detector further comprises a four-way distribution valve, a high-pressure pipe and a connecting rod. The first end of the four-way distribution valve is communicated with the gas pipe, the second end of the four-way distribution valve is communicated with the gas pressure meter, and the third end of the four-way distribution valve is communicated with the water inlet in the water-gas separation tank through the high-pressure pipe. The gas pressure detector mainly solves the problem that in the prior art, gas pressure measurement is inaccurate, enables gas to be completely separated from confined water in a coal seam in the coal seam pressure detecting process, and eliminates the water pressure factor affecting coal seam gas pressure.

Owner:JIANGSU MEIKE ELECTROMECHANICAL EQUIP MFG

Shear seal blowout preventer

ActiveUS20130299172A1Prevent pressure leaksMinimize cutting forceDrilling rodsFluid removalCoiled tubingCutting force

A shear / seal ram provides a knife edge at the shearing edge and the knife edge is inclined to minimize the cutting force required and to leave a clean cut edge. The knife edge is presented in an opening of the ram, thus the opening is positioned at the axis of the BOP, and consequently the coiled tubing, before the coiled tubing is run through the BOP. A biasing means, such as for example a Bellville spring, forces a sealing sleeve against the underside of the ram to prevent leakage of pressure from below the BOP. Similarly, a plurality of biasing means, referred to herein as “skates”, forces the ram down against the sealing sleeve to seal pressure from above the BOP.

Owner:NAT OILWELL VARCO LP

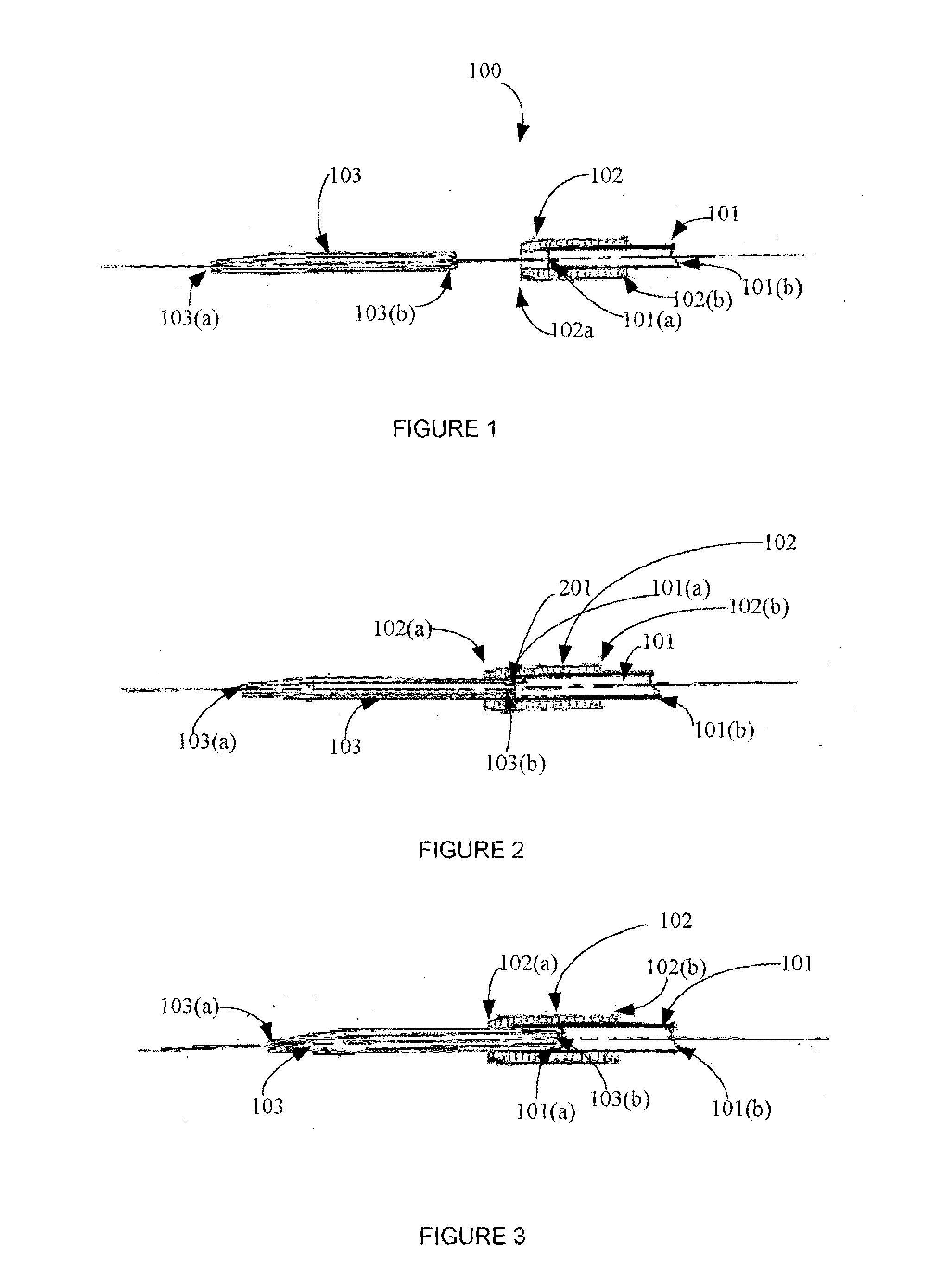

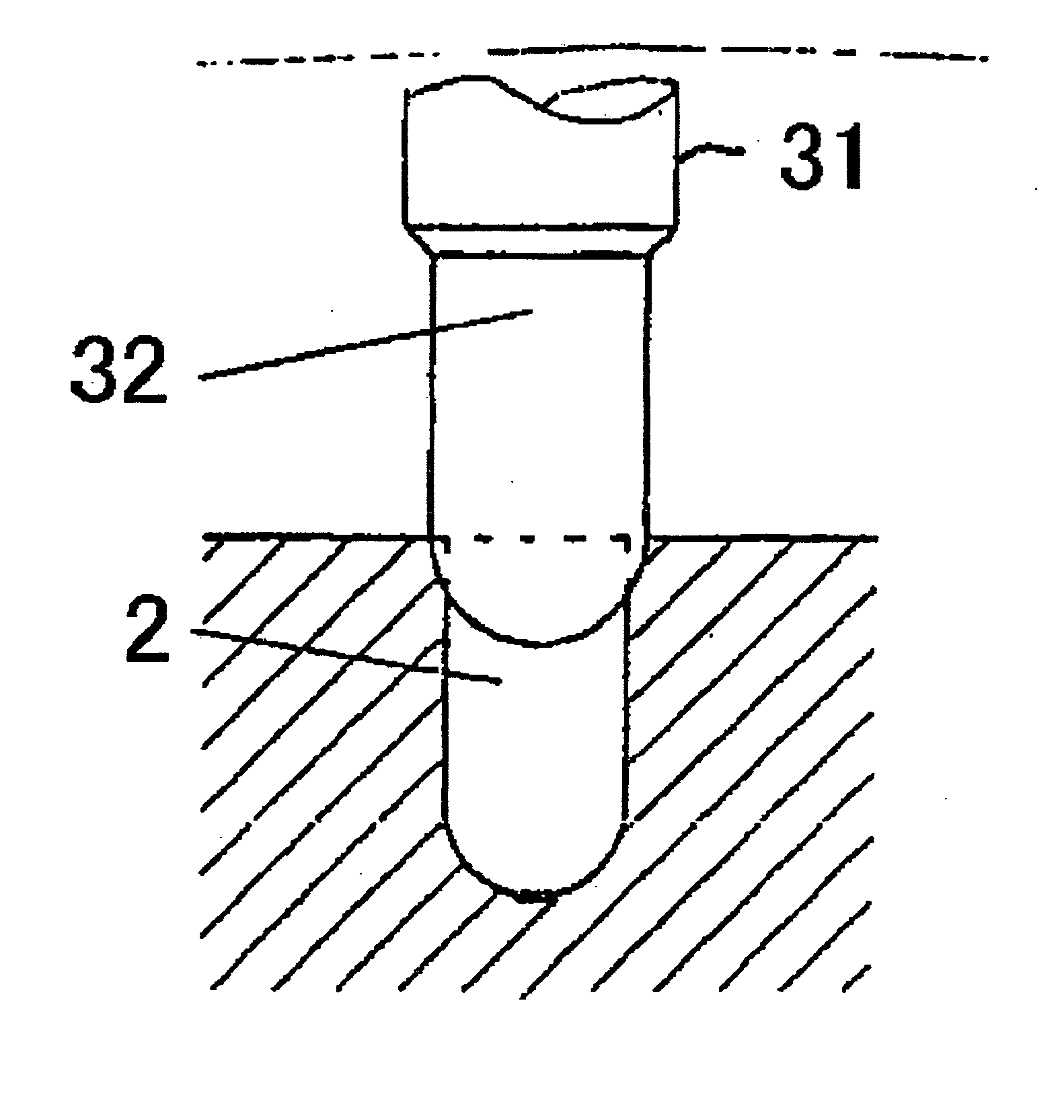

Internal surface treating method of hole before tapping on aluminumdiematerial, internal surface of hole processed casting structure, and industrial tool of internal surface improvement

InactiveUS20060042070A1Prevent pressure leaksImproves internal surfaceMetal rolling stand detailsMetal working apparatusIndustrial toolNonferrous metal

The present invention provides a improvement method of an internal surface of a hole of a casting in which an internal surface of a hole formed in a casting made of nonferrous metal is processed at high speed without excessively heating the same, thereby splitting and eliminating casting nests which are peculiar to the casting, and metal structure is reformed so that fluid does not leak from the casting nests formed in the casting, and to provide a casting structure whose hole internal surface of is improved, and a processing tool of the internal surface. A tool having a cross section area greater than that of a hole formed in the casting is sent and press-fitted into the hole while rotating the tool, friction heat is generated between a surface of the tool and the internal surface of the hole and then, the tool is pulled out from the hole in a state in which the rotation of the tool is maintained, thereby reforming a metal structure of the internal surface to form a reformed layer.

Owner:FULL CHU CORP

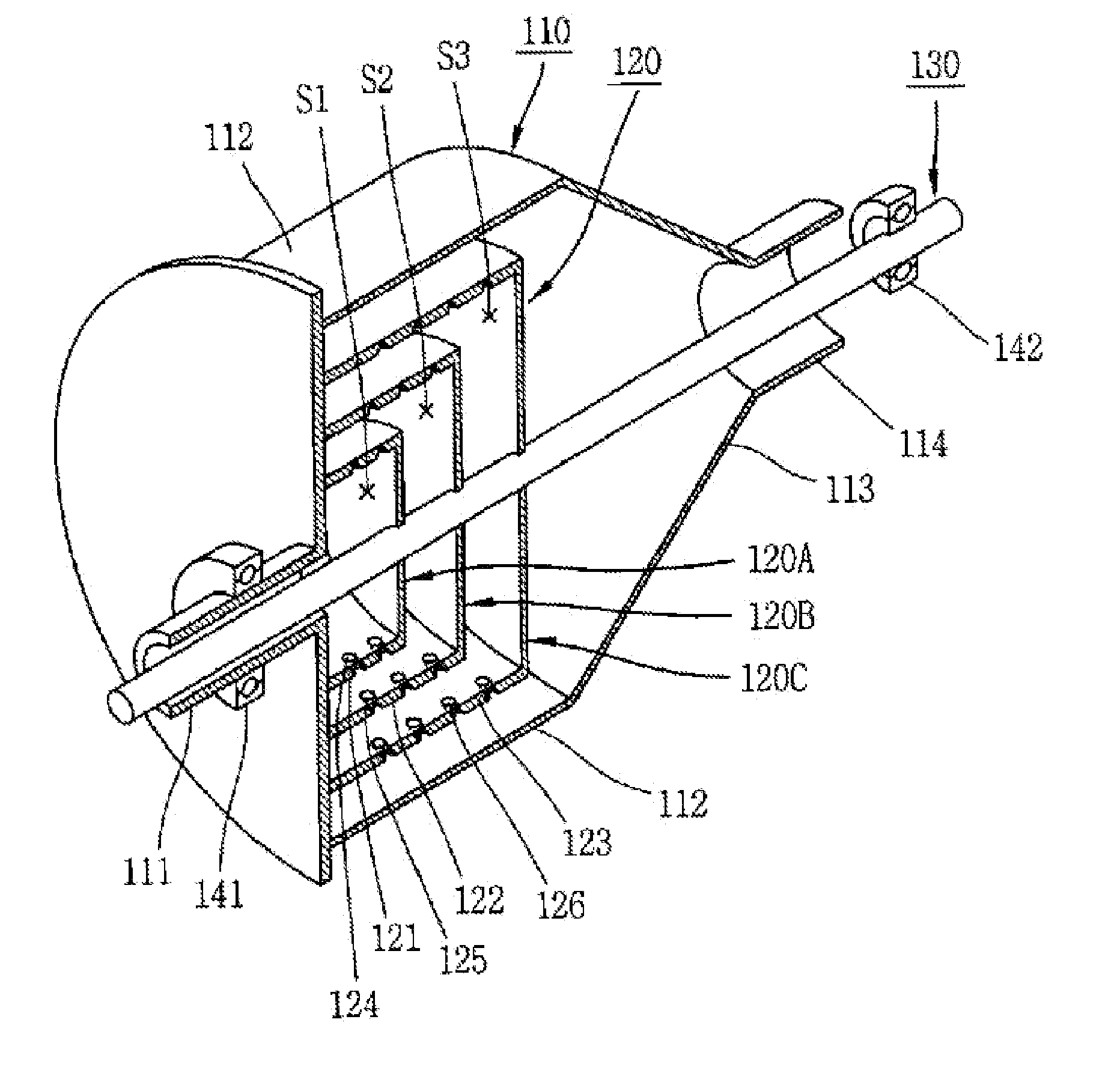

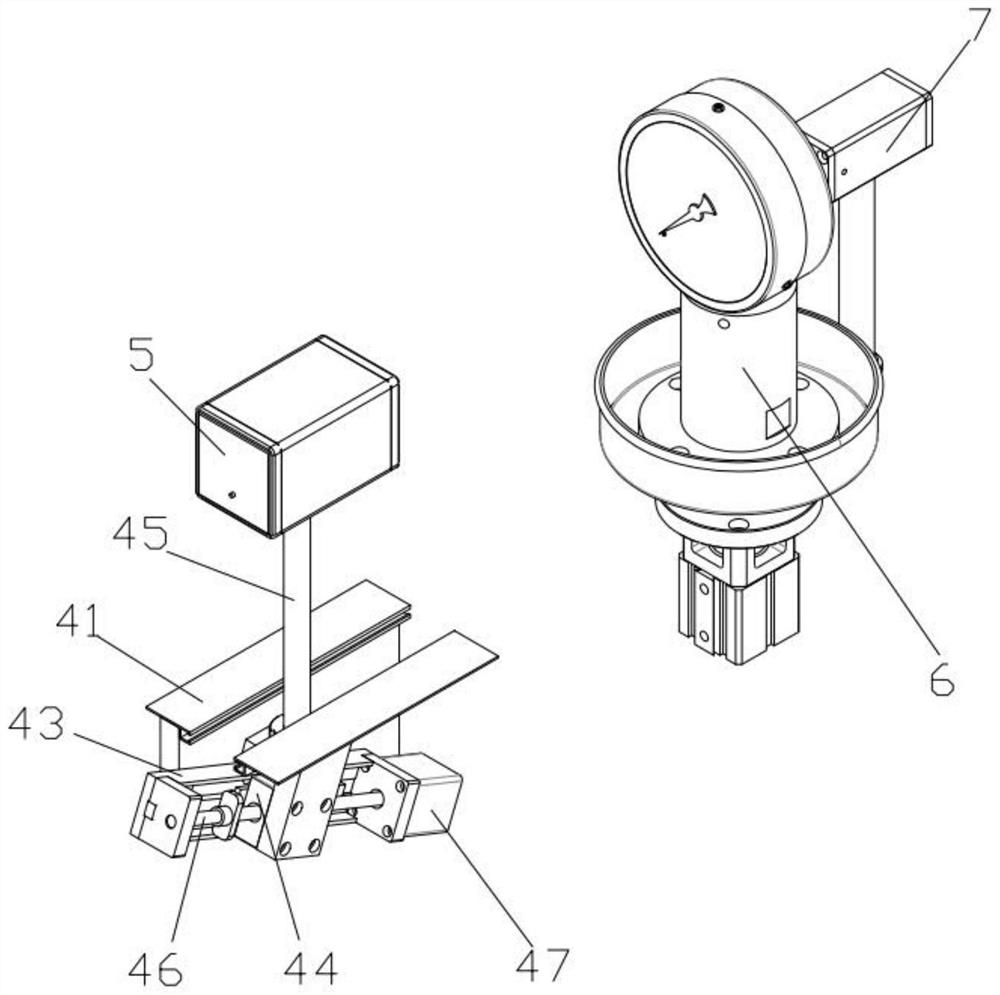

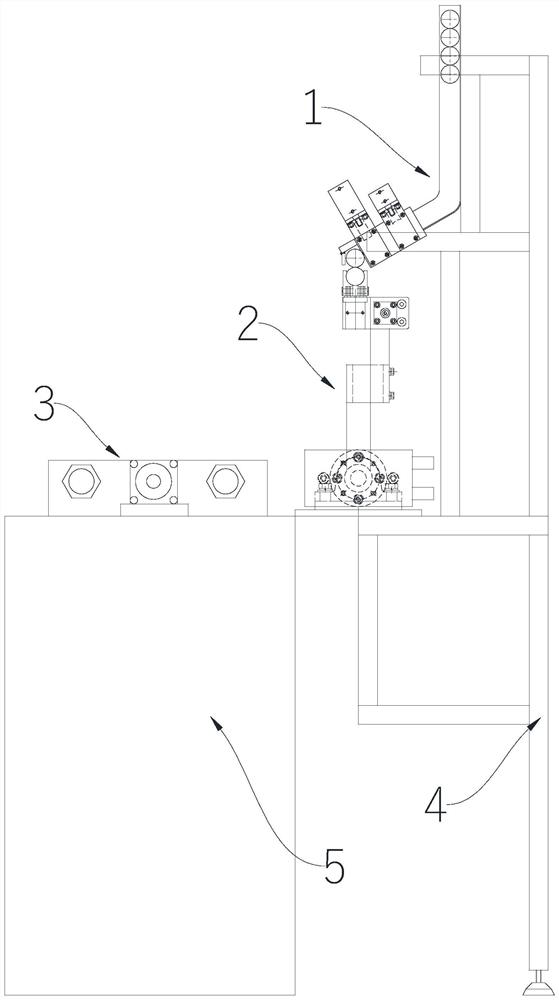

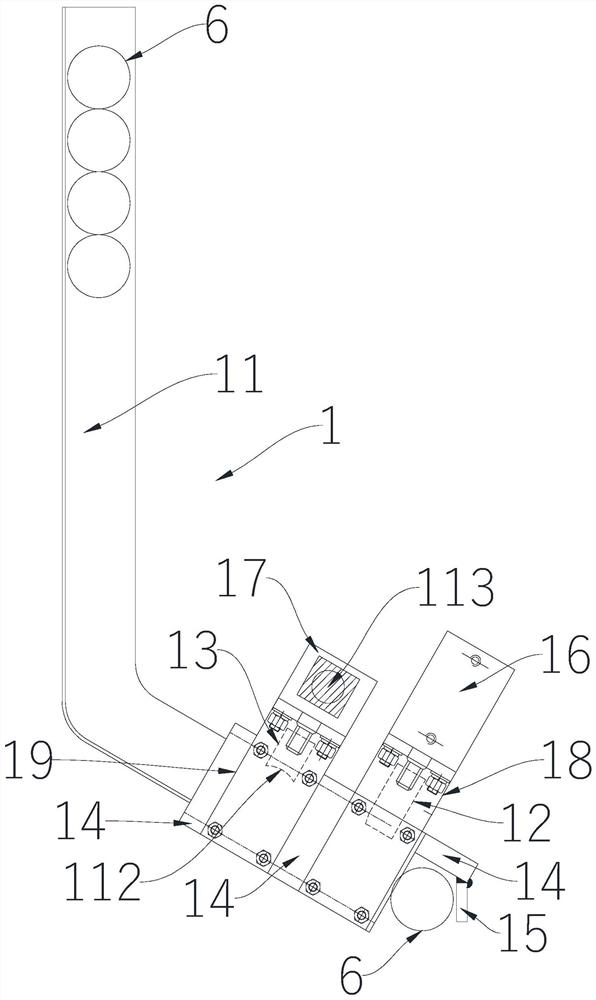

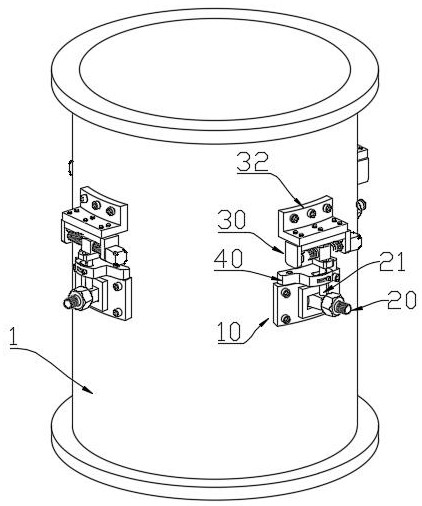

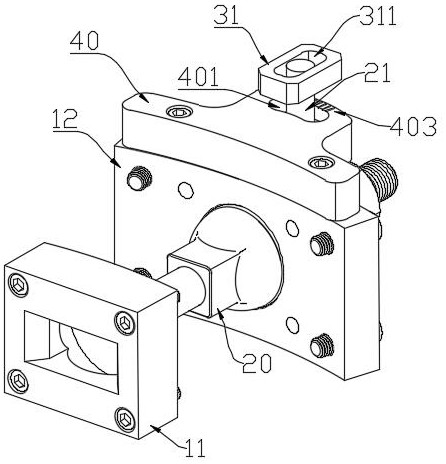

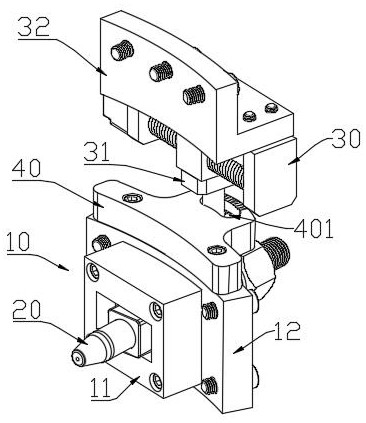

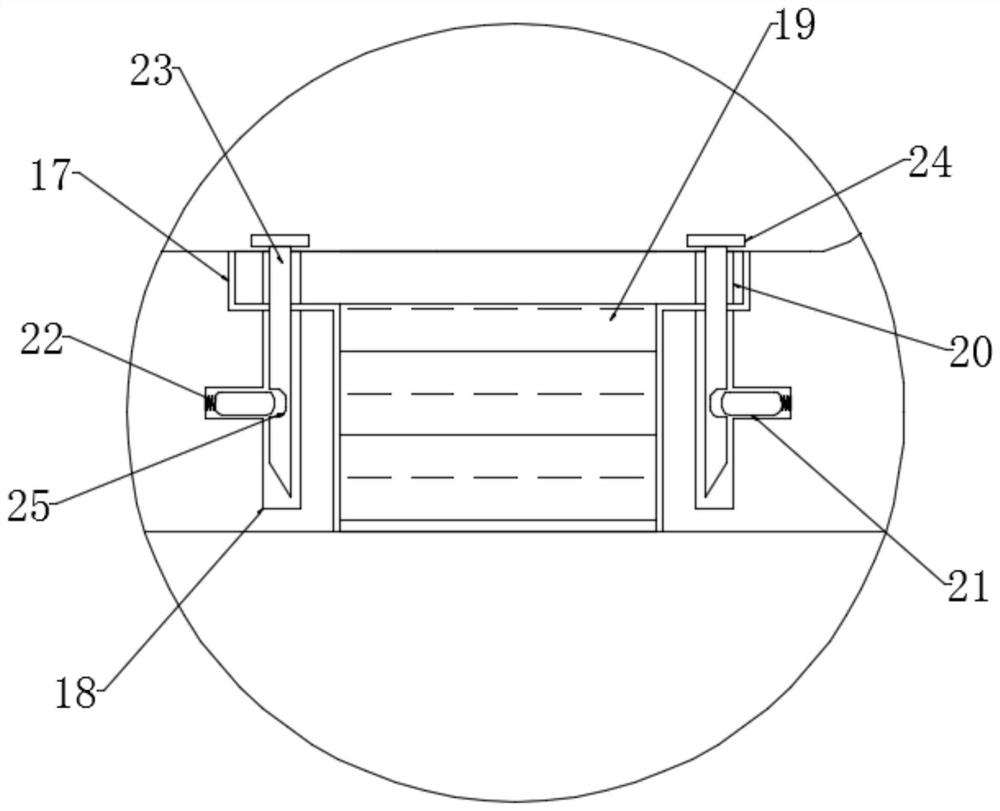

Automatic feeding and assembling system for rear cradle bearing

PendingCN112809334ARealize automatic feedingQuality assuranceMetal working apparatusRotational axisClassical mechanics

The invention relates to an automatic feeding and assembling system for a rear cradle bearing. The system comprises two discharging mechanisms arranged side by side, a feeding turnover mechanism and a press-fitting mechanism, each discharging mechanism comprises a stock bin, and a baffle and a pressing plate that are installed at the lower end of the stock bin, the baffles and the pressing plates can stretch into the stock bins from the upper side faces of the stock bins, the pressing plates are arranged above the baffles, the feeding turnover mechanism comprises two clamping finger blocks which are arranged corresponding to the two discharging mechanisms respectively and can move oppositely, the two clamping finger blocks are installed on the same rotating shaft through connecting pieces respectively, the press-fitting mechanism comprises a positioning seat and bearing pressure heads which are installed at the two ends of the positioning seat and are oppositely arranged, the two bearing pressure heads can move oppositely, and the clamping finger blocks correspond to discharge holes of the stock bins and the bearing pressure heads respectively before and after rotation. According to the automatic feeding and assembling system, automatic feeding, conveying and press-fitting of bearings can be achieved, the labor cost is reduced, the assembling efficiency is improved, the situation of pressure leakage is avoided, and the overall quality of the rear cradle is guaranteed.

Owner:常州豪爵铃木摩托车有限公司

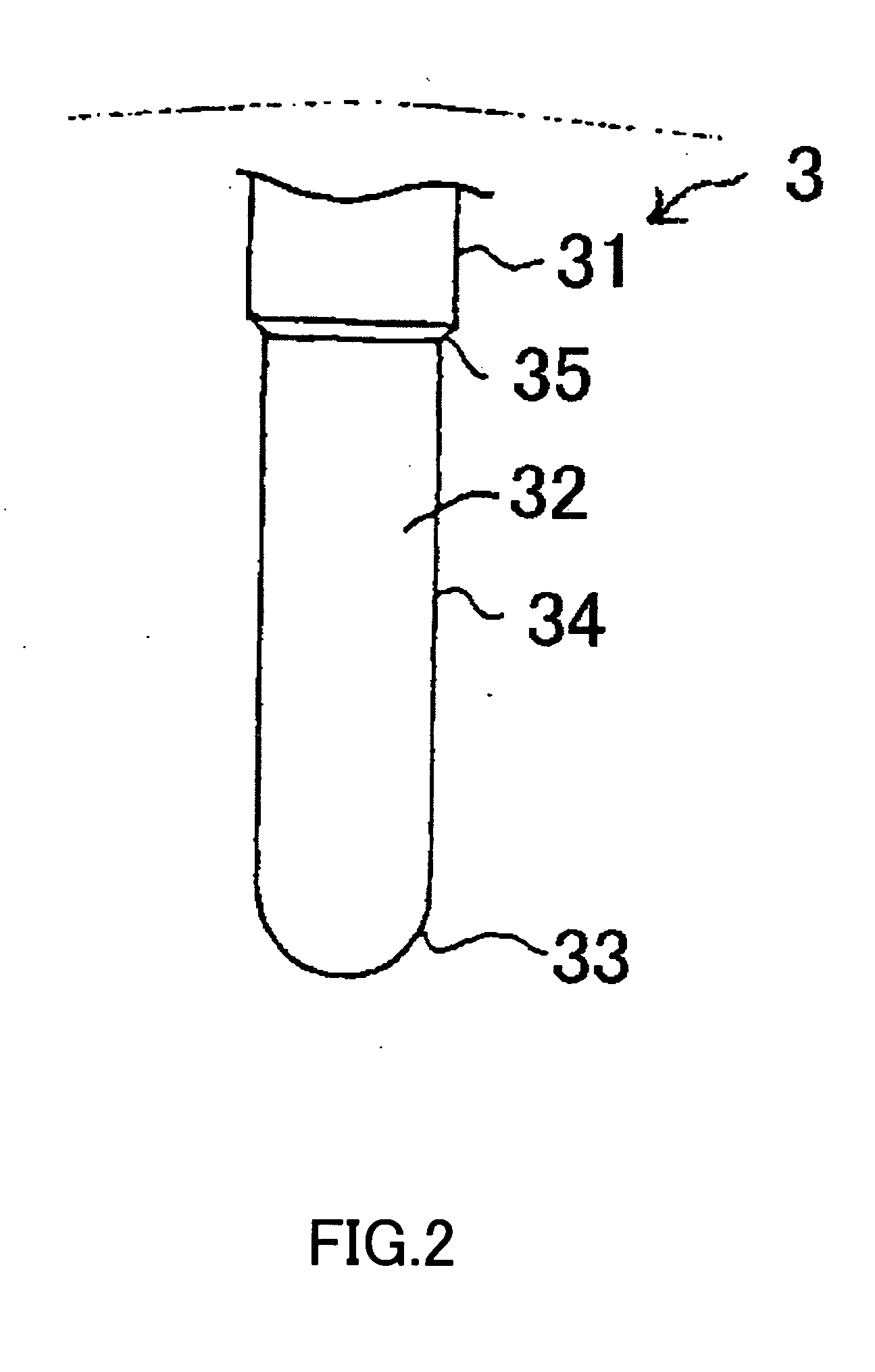

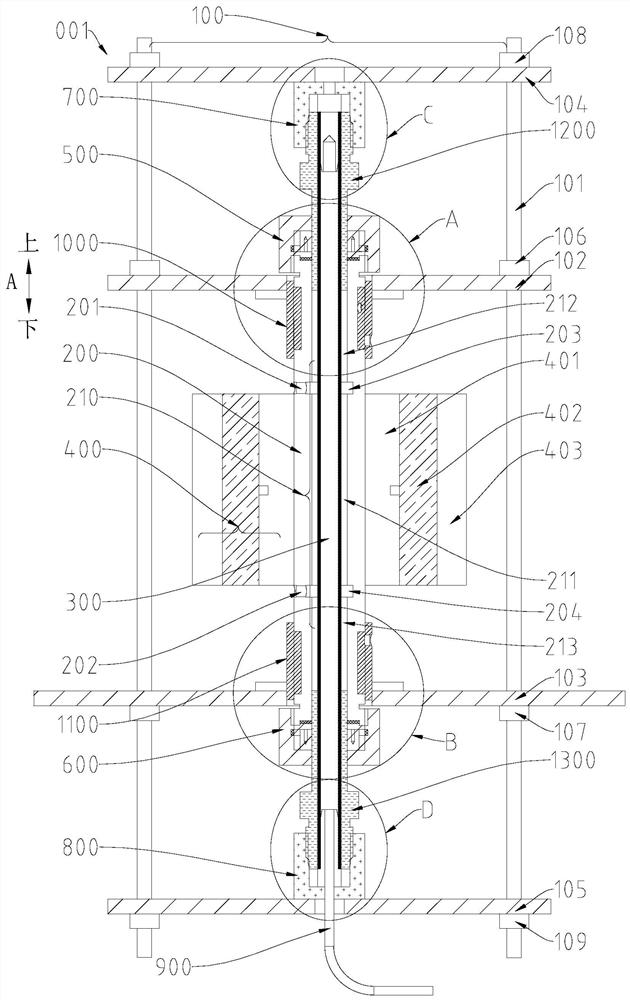

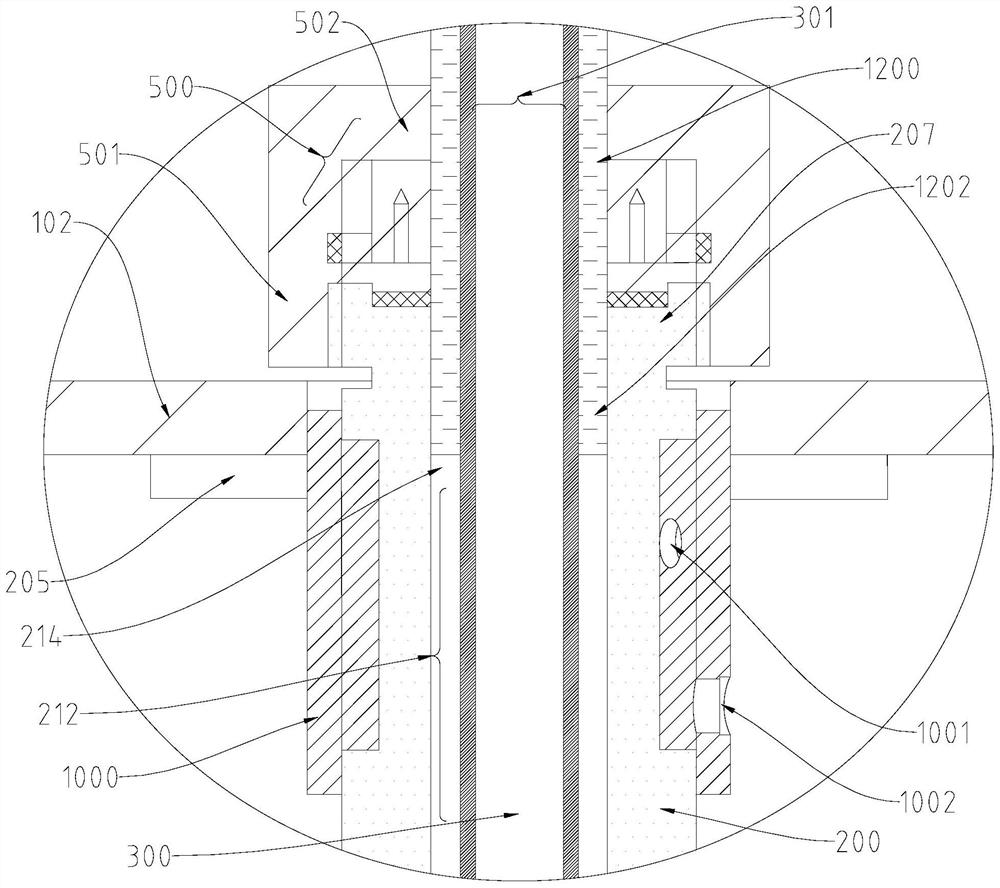

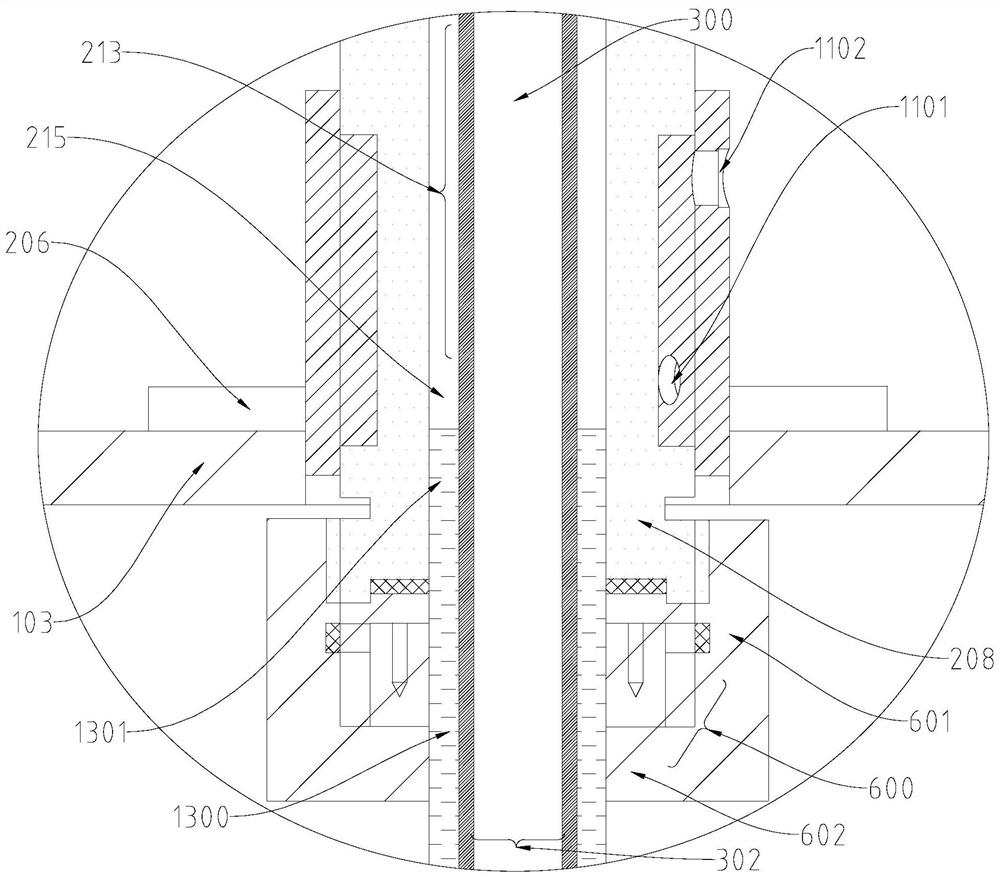

Pressurization test device for cladding tube

ActiveCN112378765AImprove accuracyPrevent pressure leaksNuclear energy generationMaterial strength using tensile/compressive forcesPhysicsTest tube

The invention discloses a pressurization test device for a cladding tube. The pressurization test device for the cladding tube comprises a test rack, a test tube, a first sealing member, a second sealing member, a third sealing member and a fourth sealing member, wherein the test tube is arranged on the test rack, the test tube sleeves a part of the cladding tube, a first part of the cladding tubeextends out of the test tube from a first end of the test tube, a second part of the cladding tube extends out of the test tube from a second end of the test tube, a test cavity is defined between the test tube and the cladding tube, and a water inlet and a water outlet which are communicated with the test cavity are formed in the peripheral surface of the test tube; the first end and the first part of the test tube are sleeved with the first sealing member, the second end and the second part of the test tube are sleeved with the second sealing member, the third sealing member is arranged atthe first end of the cladding tube, and the fourth sealing member is arranged at the second end of the cladding tube. The pressurization test device for the cladding tube can be used for carrying outa simulation test of in-tube pressurization on the cladding tube in a high-temperature and high-pressure water environment.

Owner:STATE POWER INVESTMENT CORP RES INST

Automatic nozzle adjusting mechanism applied to fluidized bed type pulverizer

PendingCN114308324AImprove efficiencyMeet crushing requirementsGrain treatmentsFluidized bedStructural engineering

The invention discloses an automatic nozzle adjusting mechanism applied to a fluidized bed type pulverizer, comprising: a plurality of mounting seats for rotatably fixing nozzles, the mounting seats being mounted on the side wall of a fluidized bed; the driving mechanism is used for controlling the nozzle to rotate, and the driving mechanism is fixed on the side wall of the fluidized bed. According to the invention, the angle of the nozzle of the fluidized bed can be adjusted, so that the crushing requirements of particles with different sizes can be met without replacing different fluidized beds, the use efficiency of the fluidized bed and the adaptability to different materials are greatly improved, and the requirements of customers are greatly met.

Owner:熊斌

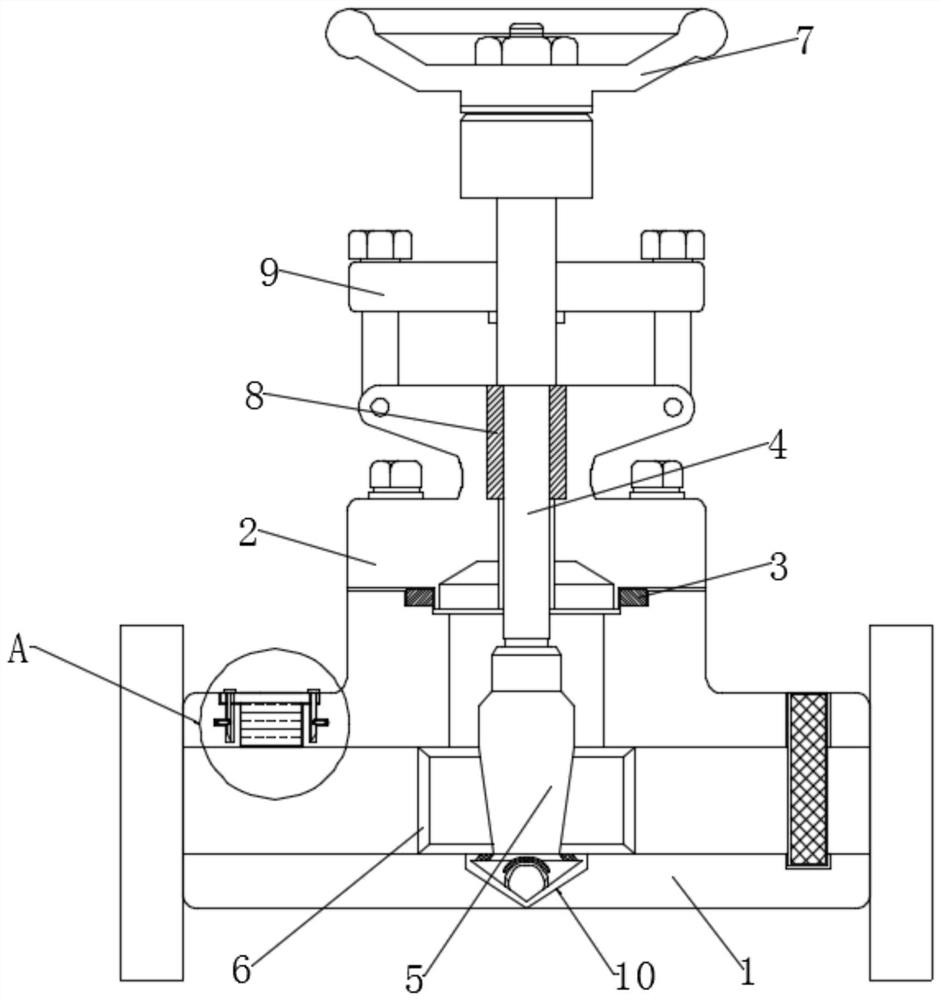

Pressure automatic leakage stopping type gate valve

InactiveCN113932026AGuaranteed uptimeWith automatic leak stopSlide valveFiltration separationEngineeringGate valve

The invention discloses a pressure automatic leakage stopping type gate valve, and belongs to the field of gate valves. According to the scheme, the problems that when a valve plate in the gate valve is still closed and is not tight after being closed and leakage occurs, generated air pressure enters pressure inlet holes in two sides and flows into air inlet holes, an expansion air bag expands under the action of pressure, a sealing piece is gradually extruded when the expansion air bag continuously expands upwards, a sealing layer is attached to the surface of the valve plate to plug the gate valve, after the sealing layer is attached to the surface of the valve plate, one layer of the surface of the sealing layer is bonded to the surface of the valve plate, the thickness of the surface of the valve plate is increased, and the phenomenon of leakage is not prone to occurring in the gate valve plugging process of the valve plate next time are solved. When the phenomenon of continuous leakage still occurs next time, the sealing layer continues to be bonded to the surface of the valve plate to plug the valve plate, so that the gate valve has the automatic leakage stopping and repairing functions after leakage, the working efficiency of the gate valve is improved, and the phenomenon that the gate valve needs to be disassembled and maintained multiple times is avoided.

Owner:浩工阀门有限公司

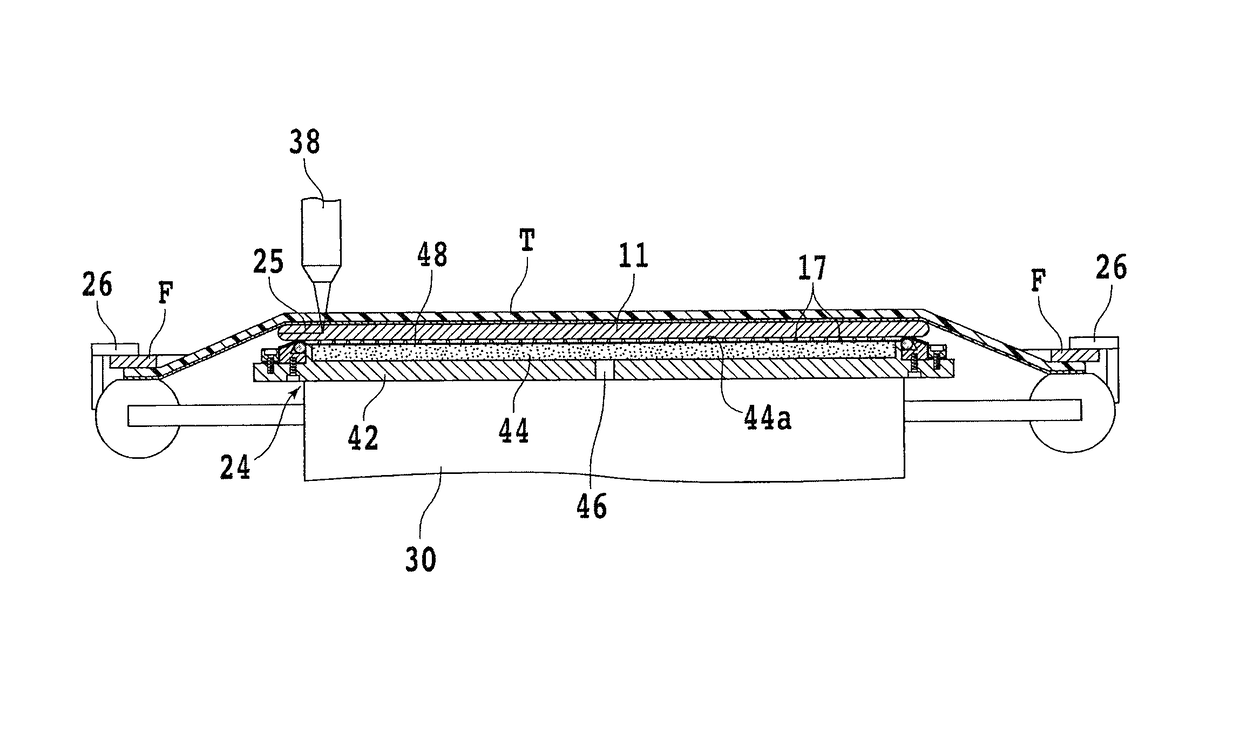

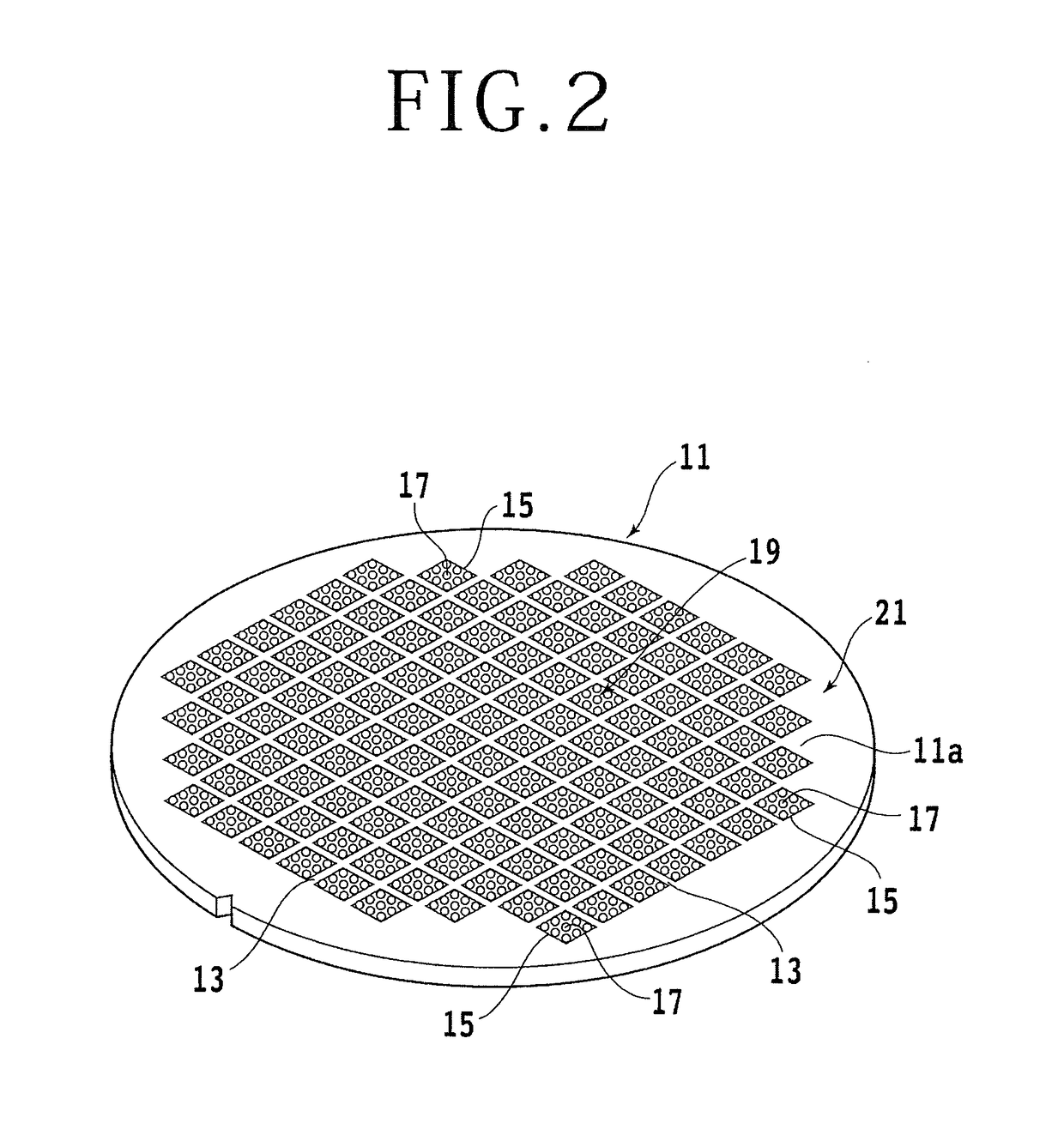

Chuck table

ActiveUS10090186B2Reliable holdPrevent pressure leaksSemiconductor/solid-state device manufacturingGrid patternEngineering

A chuck table holds under suction a front side of a wafer which includes a device region including a plurality of devices, each having a plurality of electrode bumps, formed in a plurality of areas demarcated in a grid pattern, and an outer peripheral extra region surrounding the device region. The chuck table includes a holding surface for facing the electrode bumps and holding under suction the device region of the wafer, and an outer peripheral extra region support surrounding the holding surface and including an elastic member projecting beyond the holding surface for supporting the outer peripheral extra region of the wafer. The outer peripheral extra region support projects from the holding surface by a distance corresponding to the height of the electrode bumps.

Owner:DISCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com