Casting die for valve shell casting of marine diesel engine and casting process of valve shell

A technology of marine diesel engine and casting process, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

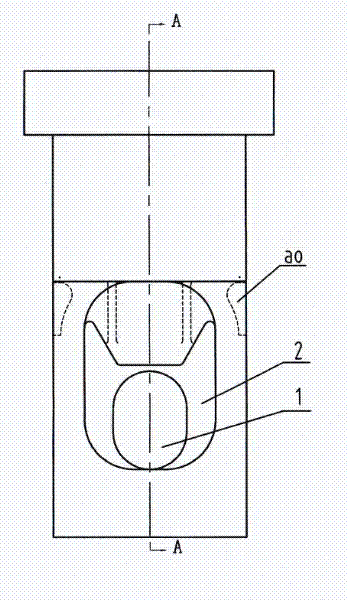

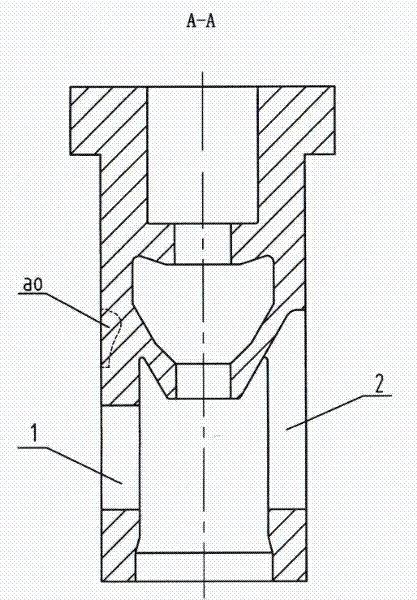

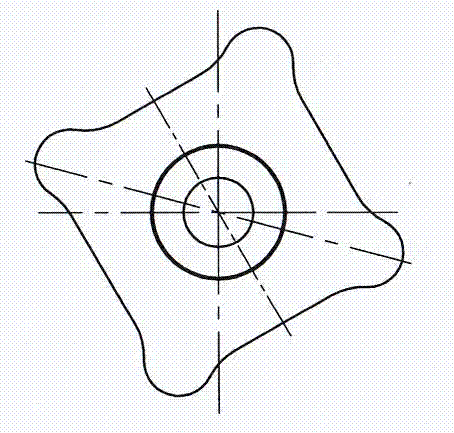

[0034] One of the specific implementation modes, as attached figure 2 , 4 shown and please refer to the attached Figure 5 .

[0035] A casting mold for castings of exhaust valve housings of medium and low-speed marine diesel engines, the casting mold is a resin sand mold, and it:

[0036] Taking the axial centerlines of the small window 1 and the large window 2 of the casting as parting surfaces, resin sand molds are used to form upper and lower cavity resin sand molds 3 and lower cavity resin sand molds 4 respectively;

[0037] Forming chills 6 are arranged on the outer end faces of the casting flange cavity 5 of the upper cavity resin sand mold 3 and the lower cavity resin sand mold 4;

[0038] The sand cores falling in the resin sand mold cavity include the first sand core 7, the second sand core 8, the third sand core 9 and the fourth sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com