Punch die and method of supplying lubricating oil

A technology of lubricating oil and lubricating oil hole, which is applied in the field of die and lubricating oil supply, can solve the problems such as the lag of the following action and the inability of the lifting ring to move up and down smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

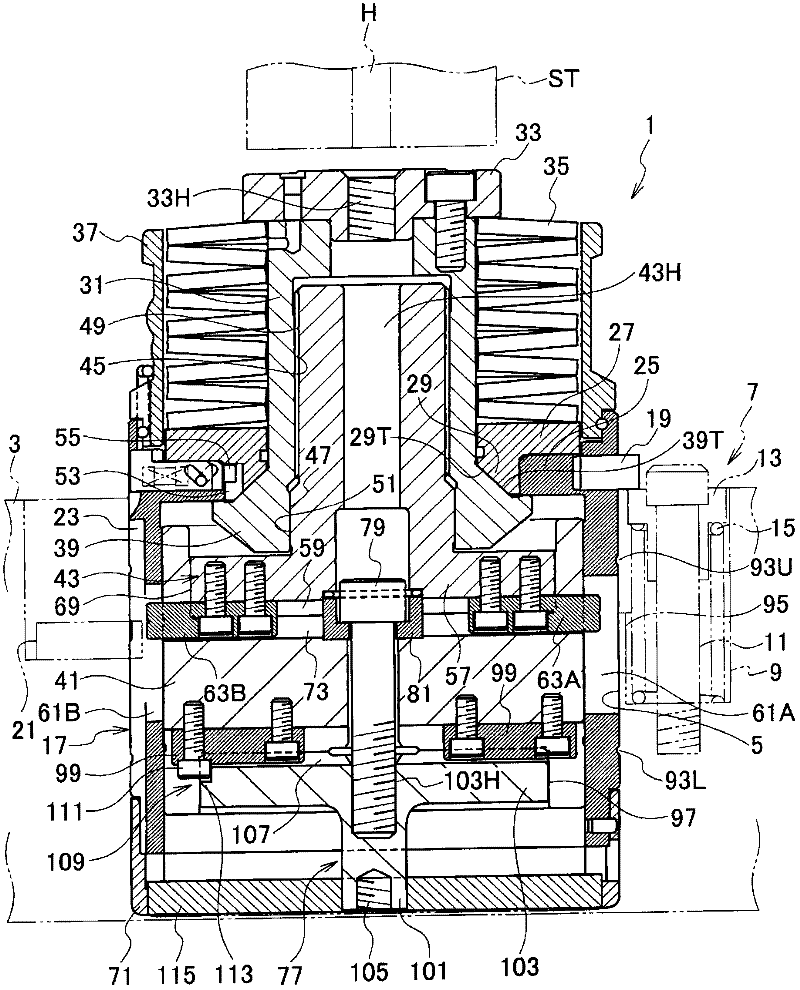

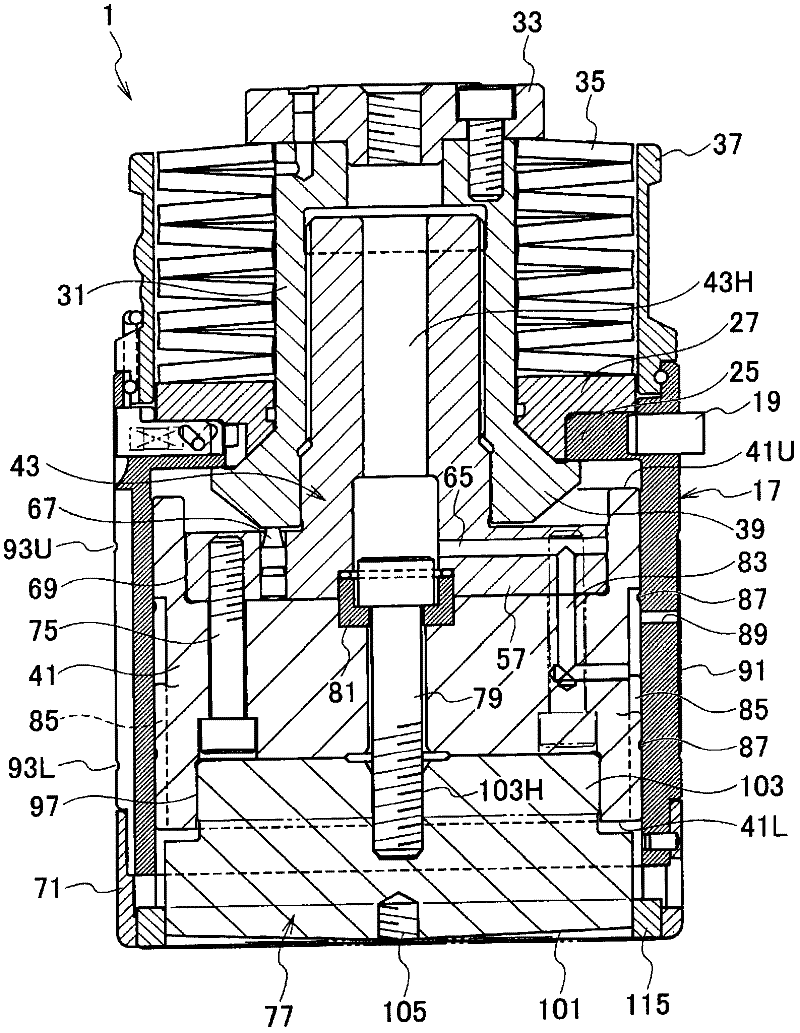

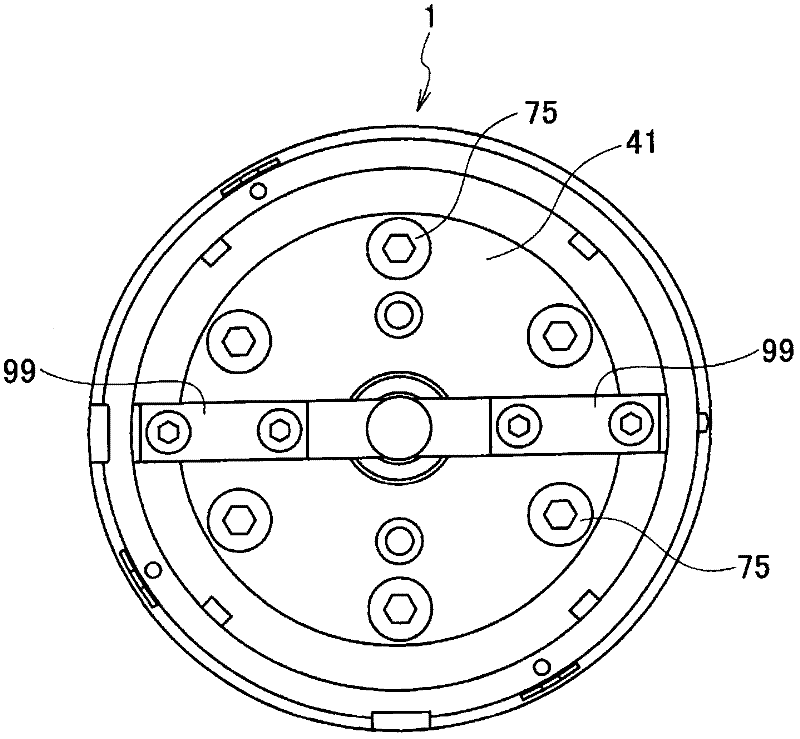

[0027] refer to figure 1 , The die 1 according to the embodiment of the present invention is used by being attached to a punch holder 3 such as an upper turret of a punch press (not shown) such as a turret punch press. The above-mentioned punch holder 3 is provided with lift springs for supporting the above-mentioned die 1 so as to freely move up and down at a plurality of places around the punch mounting hole 5 where the above-mentioned die 1 is fitted and installed so as to move freely up and down. 7. More specifically, lifting spring receiving holes 9 are provided at a plurality of positions of the punch holder 3 around the punch mounting hole 5, and screws (guide members) 11 are erected in the lifting spring receiving holes 9, An elastic member 15 such as a coil spring is elastically interposed between a lifting ring 13 fitted to the screw 11 so as to be freely movable up and down, and the bottom of the above-mentioned lifting spring receiving hole 9 . In addition, since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com