Automatic-control constant-pressure throttling valve

A technology of throttle valve and inlet pressure, applied in valve details, safety valve, balance valve, etc., can solve the problems of automatic take-off and excessive pressure change of safety valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

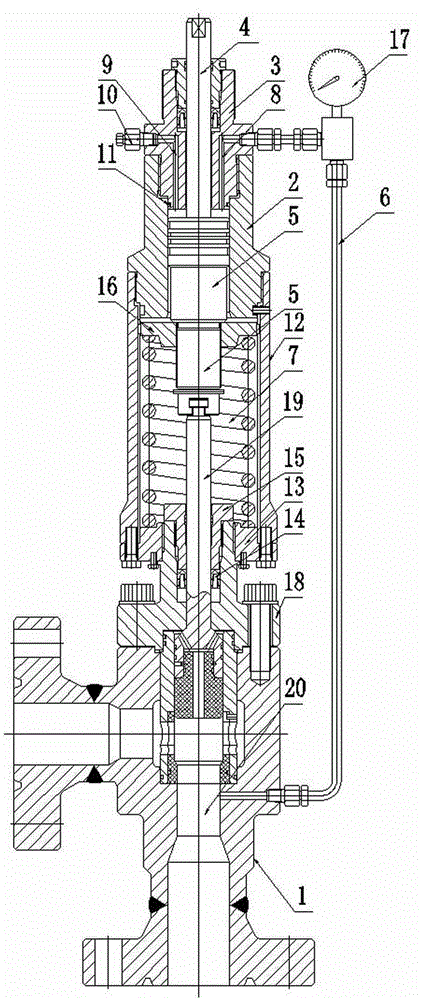

Embodiment 1

[0027] A self-controlled constant pressure throttle valve, including a valve body 1 and an actuator, the actuator includes a cylinder 2, a cylinder head 3, a piston 5, a pressure taking tube 6 and an elastic element, and the cylinder 2 is fixed on the valve Above the main body 1, the cylinder head 3 is fixed on the upper part of the cylinder body 2, the piston 5 is movably arranged in the cylinder body 2, and the lower part of the piston 5 is fixed on the valve stem 19 of the valve main body 1, and the elastic element is fixedly arranged Between the cylinder body 2 and the valve main body 1, and the elastic element is fixedly connected with the piston 5; Set above the piston 5 in the cylinder body 2; when the pressure at the output end 20 of the valve main body 1 increases, the medium pressure is transmitted to the top of the piston 5 through the pressure sensing tube 6 to make the piston 5 move down, and the piston 5 indirectly drives the valve stem 19 and the valve. The flap...

Embodiment 2

[0035]A self-controlled constant pressure throttle valve, including a valve body 1 and an actuator, the actuator includes a cylinder 2, a cylinder head 3, a piston 5, a pressure taking tube 6 and an elastic element, and the cylinder 2 is fixed on the valve Above the main body 1, the cylinder head 3 is fixed on the upper part of the cylinder body 2, the piston 5 is movably arranged in the cylinder body 2, and the lower part of the piston 5 is fixed on the valve stem 19 of the valve main body 1, and the elastic element is fixedly arranged Between the cylinder body 2 and the valve main body 1, and the elastic element is fixedly connected with the piston 5; Set above the piston 5 in the cylinder body 2; when the pressure at the output end 20 of the valve main body 1 increases, the medium pressure is transmitted to the top of the piston 5 through the pressure sensing tube 6 to make the piston 5 move down, and the piston 5 indirectly drives the valve stem 19 and the valve. The flap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com