Pressure-maintaining core sampler flap valve with multi-stage sealing structure

A technology of sealing structure and corer, which is applied in the direction of lift valve, valve device, mechanical equipment, etc., can solve the problems of easy sealing failure, leakage of corer, and inability to maintain pressure, so as to improve the anti-deformation ability and avoid pressure. Leakage, the effect of preventing valve leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

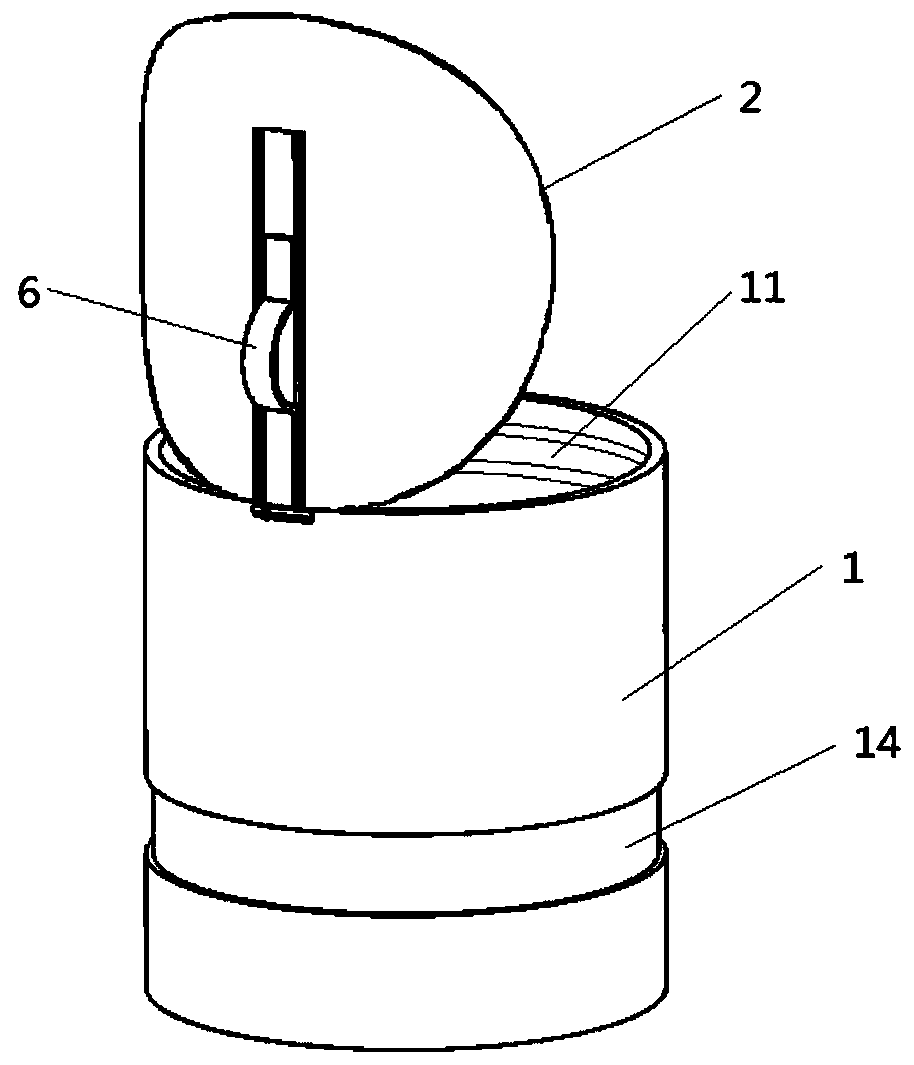

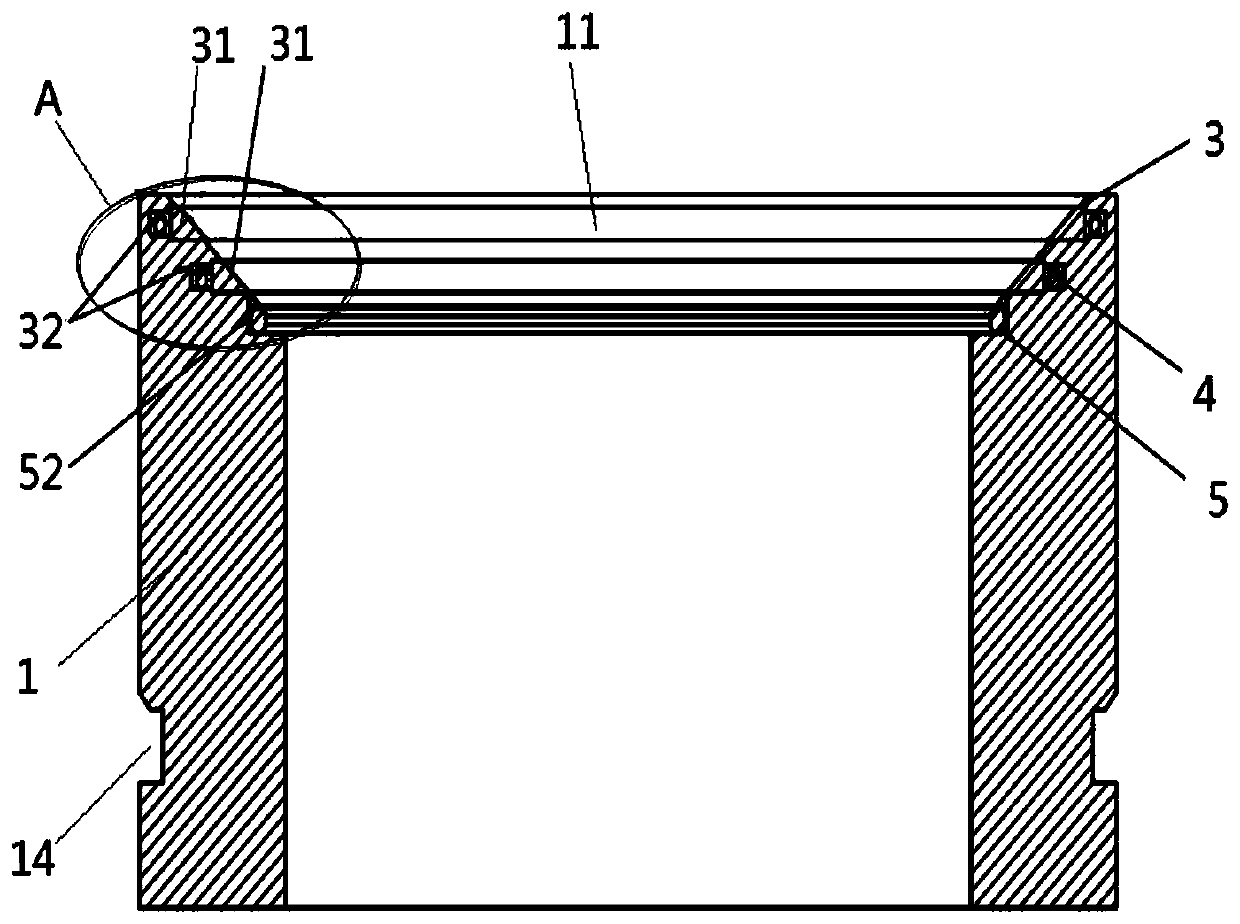

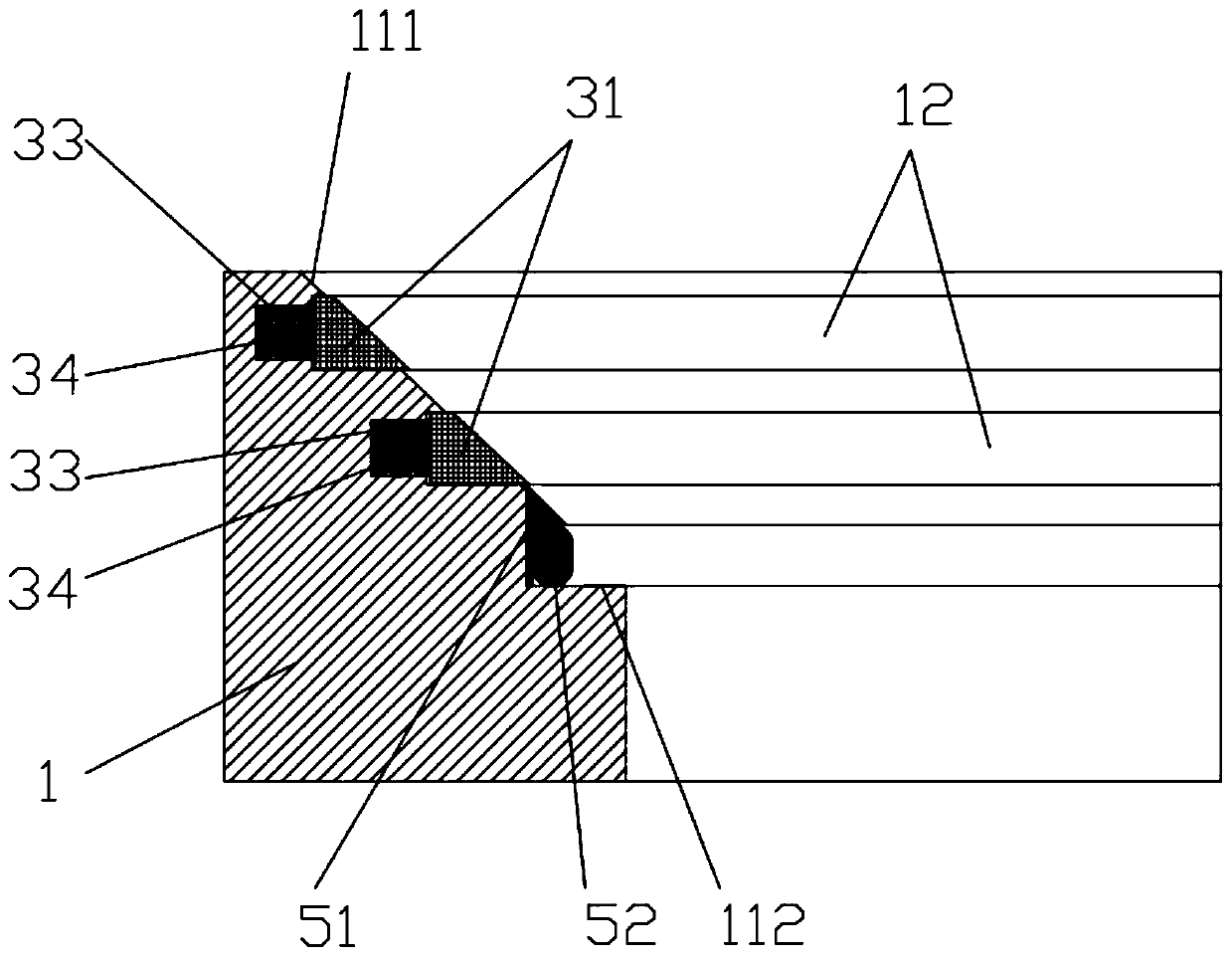

[0032] Such as figure 1 As shown, the pressure-maintaining core remover flap valve with a multi-stage sealing structure disclosed in this embodiment includes a valve seat 1 and a valve disc 2, one end of the valve disc 2 is movably connected to the upper end of the valve seat 1, and the valve disc 2 is connected by a spring plate 6 and the rotating shaft are movably connected on the valve seat 1, and the outer wall of the top end of the valve seat 1 has a rotating shaft accommodation groove that matches the rotating shaft, and the rotating shaft is installed in the rotating shaft accommodation groove, and the outer surface of the valve disc 2 has a shrapnel for accommodating the spring piece 6 Accommodating groove, spring leaf 6 is contained in the shrapnel accommodating groove. The spring piece 6 is a curved steel piece, which is stuck in the shrapnel holding groove, and the curved steel piece can be straightened under the action of an external force, and its curved surface c...

Embodiment 2

[0046] Since the traditional core taker flap valve is triggered by the shrapnel and relies on the gravity of the valve disc to realize the cooperative action, it can only drill in near-vertical conditions.

[0047] Therefore, in this embodiment, a magnet is provided on the valve seat 1 , and a magnetic material is provided on the valve disc 2 . The magnet can be an NdFeB magnet, and the disc 2 is made of 20CrMnMo carburizing steel. The shape, position and quantity of the magnets are set as required. This embodiment only mentions two of them, but is not limited to these two configurations.

[0048] The first type, such as Figure 7 As shown, an annular magnet 6 is installed on the valve seat 1, and the position of the annular magnet 6 is set as required. The annular magnet 6 can be arranged below the sealing groove 16 of the valve seat, and can also be arranged above the sealing groove 16 of the valve seat.

[0049] The second type, such as Figure 8 As shown, the sheet ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com