Rotary compressor

A technology of rotary compressor and compression chamber, applied in rotary piston machinery, rotary piston pump, rotary piston/oscillating piston pump components, etc., can solve problems such as pressure leakage of compression chamber, and prevent pressure leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

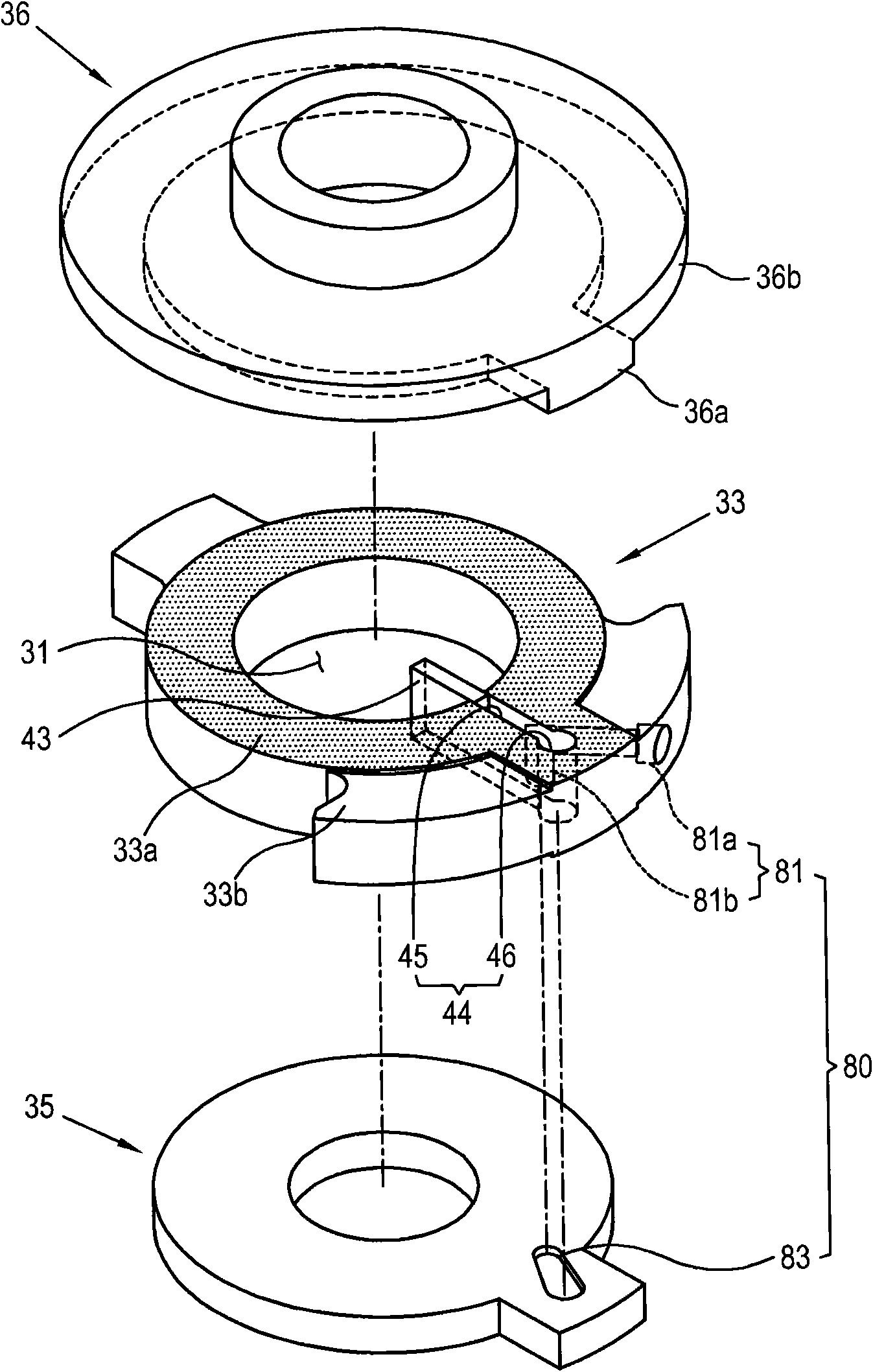

[0030] Below, refer to Figure 2 to Figure 7 A first embodiment of the rotary compressor according to the present invention will be described in detail.

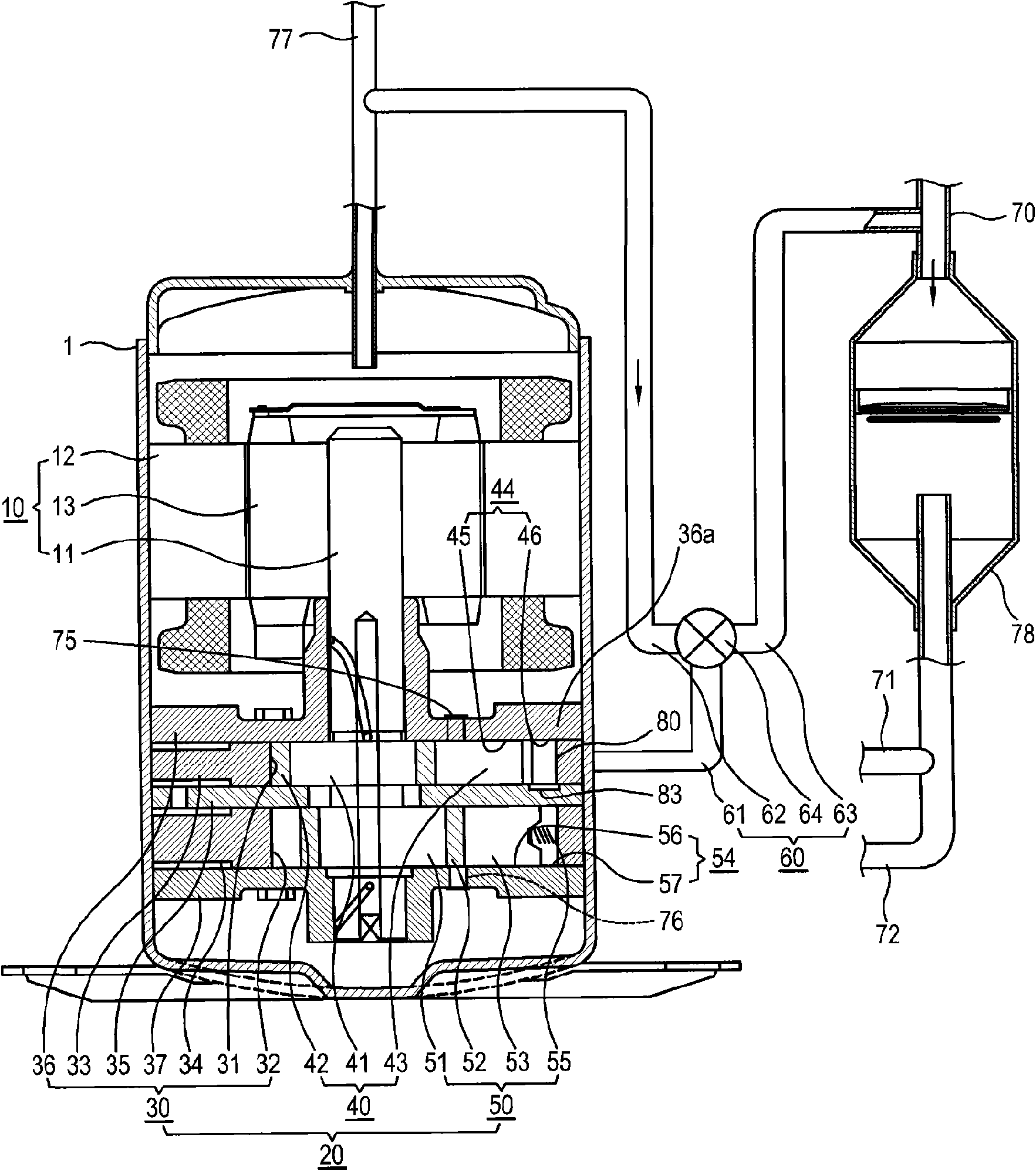

[0031] like figure 2 As shown, the rotary compressor according to this embodiment has a casing 1 forming an appearance, an electric mechanism 10 disposed on the inner upper portion of the casing 1 , and an electric mechanism 10 disposed on the inner lower portion of the casing 1 and connected to the electric mechanism 10 through a rotating shaft 11 The compression mechanism 20.

[0032] The motor mechanism 10 includes a cylindrical stator 12 provided inside the casing 1 , and a rotatable rotor 13 provided inside the stator 12 and coupled to the rotating shaft 11 at its center. The motor mechanism 10 drives the compression mechanism 20 connected via the rotating shaft 11 according to the rotation of the rotor 13 when the power is turned on.

[0033] The compression mechanism 20 has: a cylinder unit 30 formed with mutually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com