Casting process of valve casing

A technology of casting technology and valve casing, which is applied in the field of casting technology of valve casings, can solve problems such as pressure leakage of valve casings, and achieve the effect of improving the purity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

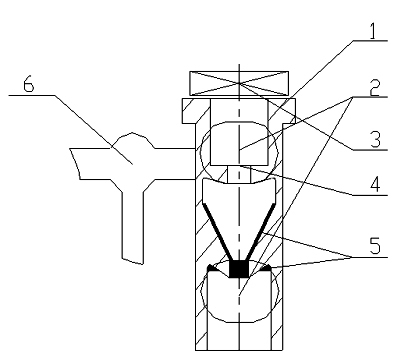

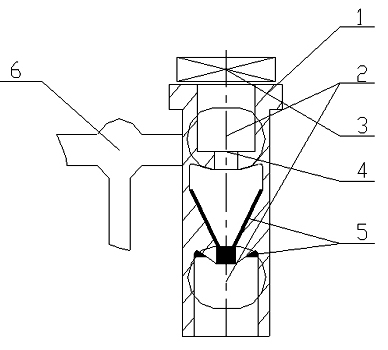

[0014] Embodiment: Two processes of smelting and casting are used to produce products 1-5; during smelting, stainless steel 1Cr13 returned charge and low-carbon scrap steel are smelted into molten steel in an intermediate frequency furnace as raw materials; wherein, 1Kg / T of aluminum is inserted 3-5 minutes before tapping For molten steel, 3Kg / T molten steel purifying agent is added to the ladle when tapping, the tapping temperature is 1590-1610°C, the pouring temperature is 1580-1600°C, and the sprue is tapped 1-2 times at intervals of 3-5S after pouring; figure 1 As shown, valve case casting mold 1 adopts two boxes of resin sand to make the core. During core making, the middle connection part of 1# mud core is connected by ceramic tube 4, and 15mm thick chromite sand 5 is placed in the part that is easy to press and leak. Valve case casting mold 1. Two 80×120×120 insulation risers are designed on the upper part. 2. The rear flange part is designed to be half of the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com