Honey filling and film sealing integrated device

A technology of sealing film and honey, applied in packaging, closures, bottle filling, etc., can solve the problems of wasting manpower and reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

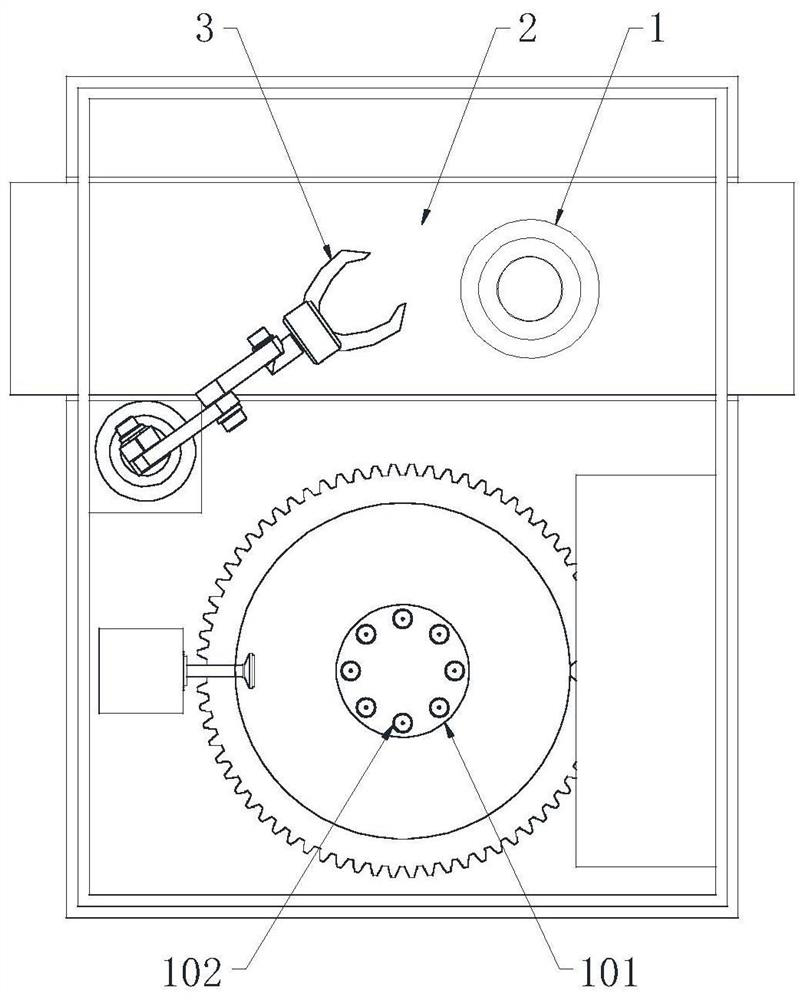

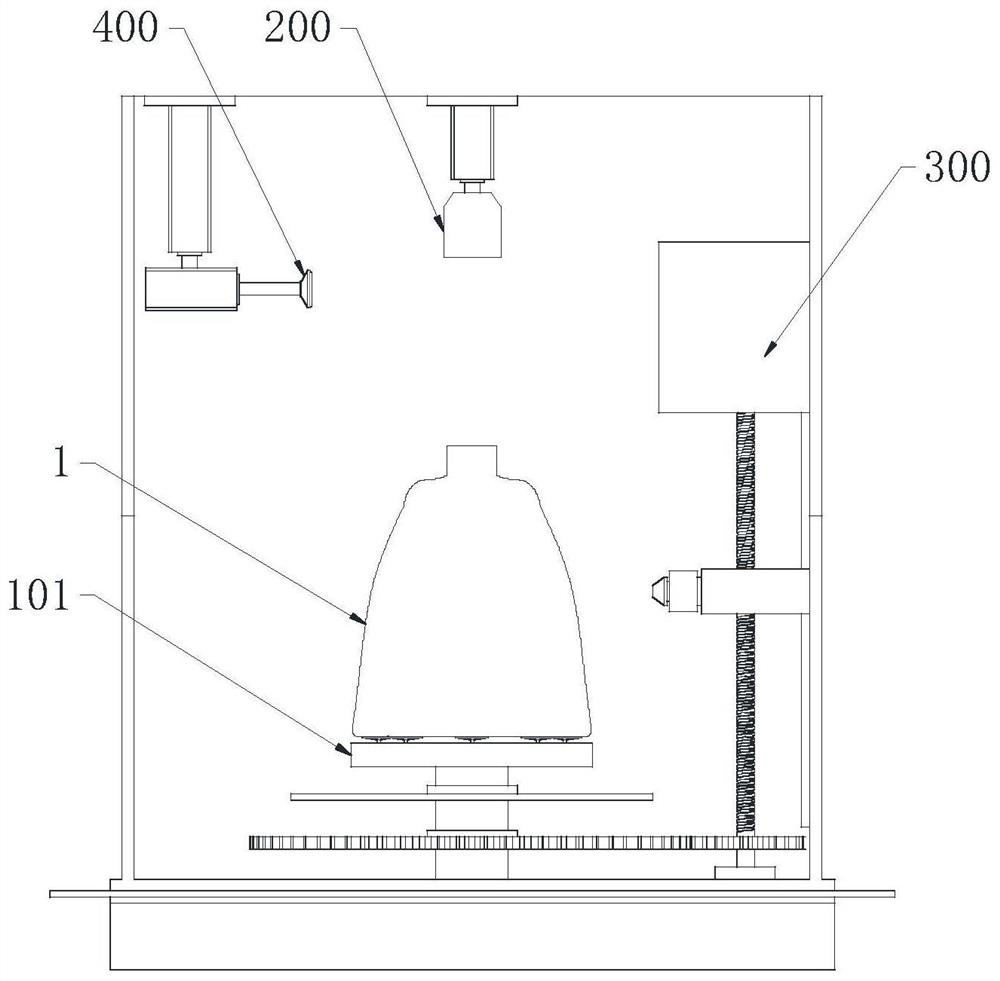

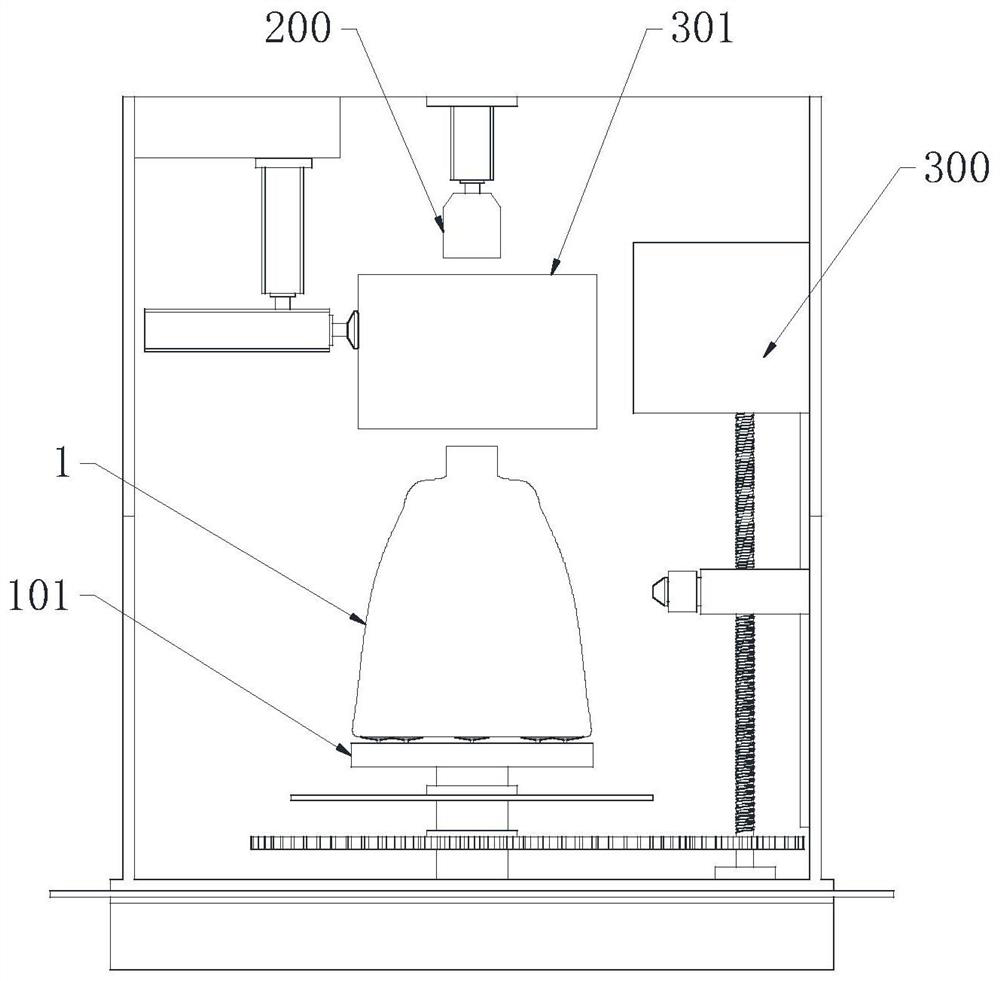

[0029] see figure 1 with 2 , is a structural schematic diagram of a device for realizing the integration of filling and sealing film of the present invention, wherein, figure 1 is a schematic diagram of the top view state, figure 2 A schematic diagram of the main view state.

[0030] figure 1 In this process, the bottle 1 filled with honey is transported to the capping, film-coating and heat-sealing integrated area via the conveyor belt 2. In this area, the bottle 1 can be capped, film-coated, and heat-sealed almost simultaneously. Sealed operation. A mechanical arm 3 is arranged beside the conveyor belt 2 to transfer the filling bottle 1 on the conveyor belt 2 to the fixed plate 101 , and fix the filled bottle 1 through the fixed plate 101 .

[0031] The fixed plate 101 is arranged on the side of the conveyor belt 2. Several suction cups 102 are fixed on the fixed plate 101, and there is a negative pressure hole in the middle of the suction cup 102. The negative pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com