Kitchen waste drying device

A drying device, a technology for kitchen waste, applied in the directions of waste drying, drying, dryers, etc., can solve the problems of non-conformity, uneven drying, deterioration, etc., to reduce the failure rate, the structure is reliable and durable, and the replacement reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

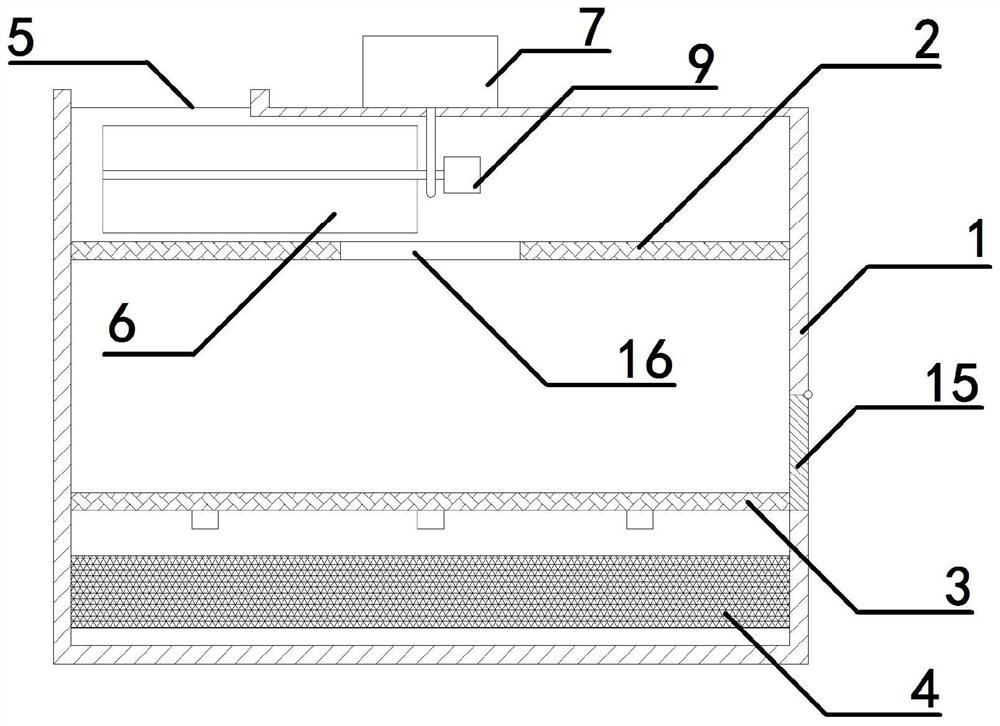

[0035] as attached figure 1 As shown, a household food waste drying device includes a box body 1 and a pre-drying layer 2, a main drying layer 3, and a heating device 4 arranged from top to bottom in the box body 1; the box body 1 The top is provided with a material inlet 5 on the edge, and the bottom of the box body 1 is provided with a discharge door 15; the pre-drying layer 2 is provided with a paving device for evenly paving materials.

[0036] The paving device includes a scraper 6 and a moving motor 7, the moving motor 7 and the scraper 6 are arranged above the pre-drying layer 2, and the moving motor 7 drives the scraper 6 to rotate horizontally along the vertical axis , the rotation of the scraper 6 will spread the material to be dried that falls from the feed port 5 to the edge of the pre-drying layer 2 and evenly distribute it on the upper surface of the pre-drying layer 2. When the material increases, the scraper 6 will Rotation will drive too much material to the ...

Embodiment example 2

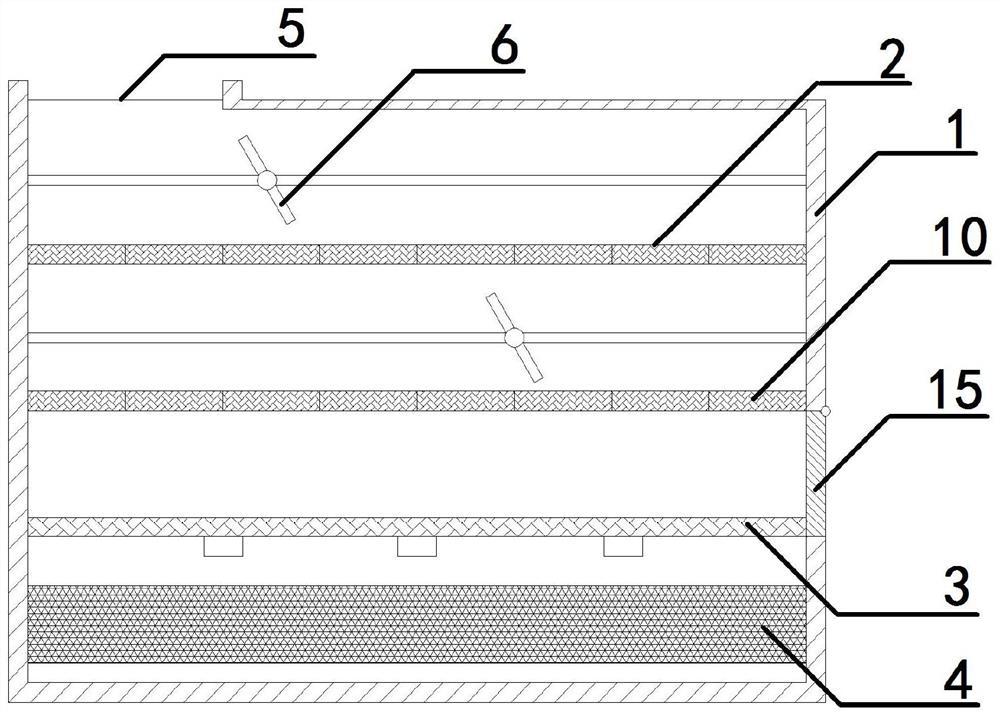

[0044] as attached Figure 2-5 As shown, a commercial kitchen waste drying device includes a box body and two pre-drying layers, a main drying layer, and a heating device arranged from top to bottom in the box body; the top of the box body is provided with a feeding mouth, the pre-drying layer is provided with a paving device for evenly paving the material.

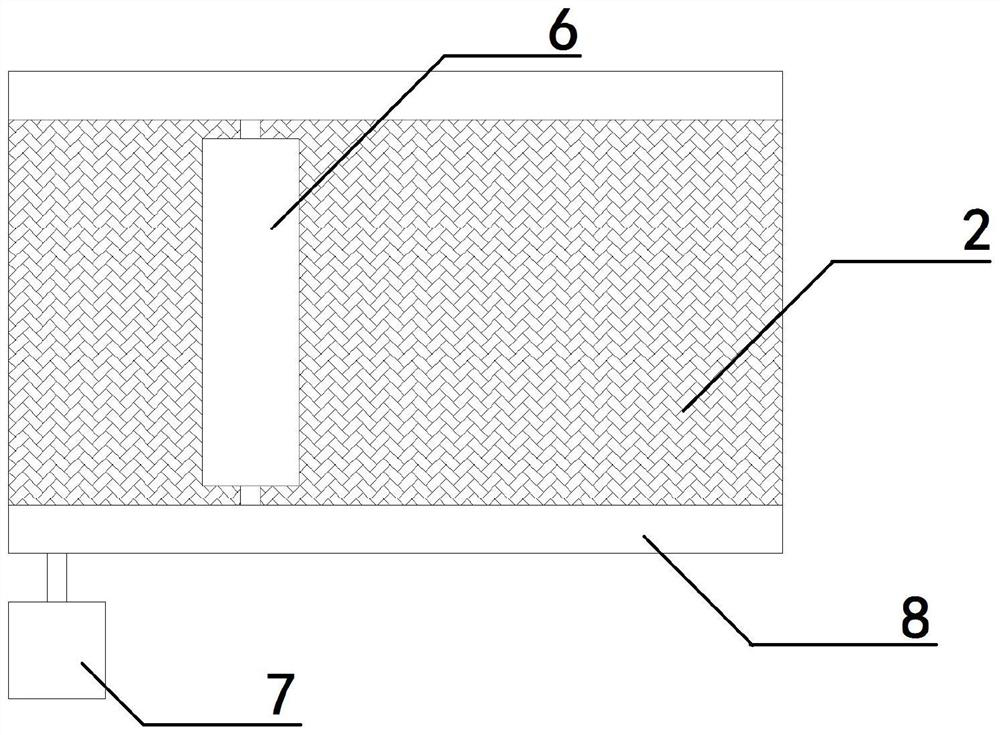

[0045] The paving device includes a scraper and a moving motor, and the moving motor drives a horizontal transmission belt to move. The scraper is arranged on the transmission belt, and is moved back and forth horizontally by the transmission belt, and will fall into the pre-drying layer from the feeding port The materials to be dried are evenly distributed on the upper surface of the pre-drying layer. The drive belt can also be a rack, chain, belt, etc.

[0046] The pre-drying layer is composed of a plurality of plate-shaped components, and the plate-shaped components are in the shape of a mesh with a plurality of hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com