LED chip and preparation method thereof and preparation method of LED display module

A technology of LED chips and display modules, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of top damage, unsatisfactory, colored lines, etc., and achieve the effect of enhancing the strength of the bottom, realizing the display effect, and increasing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

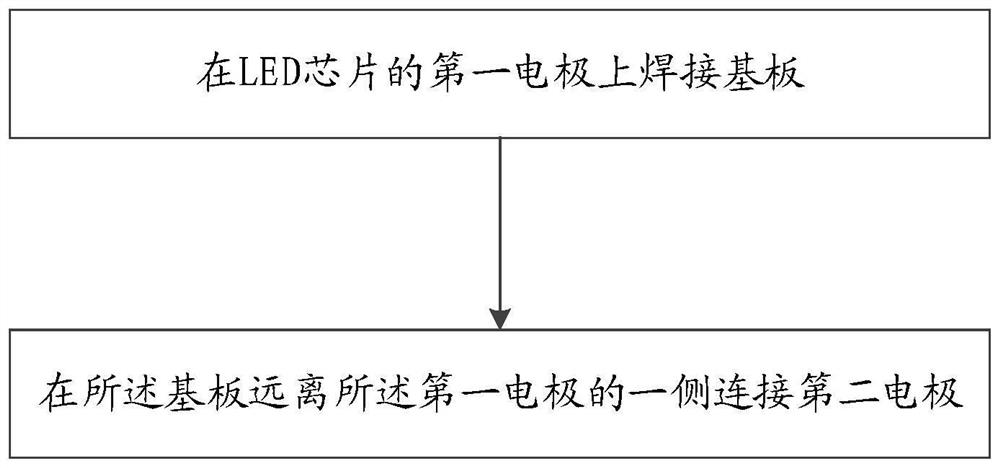

Method used

Image

Examples

Embodiment Construction

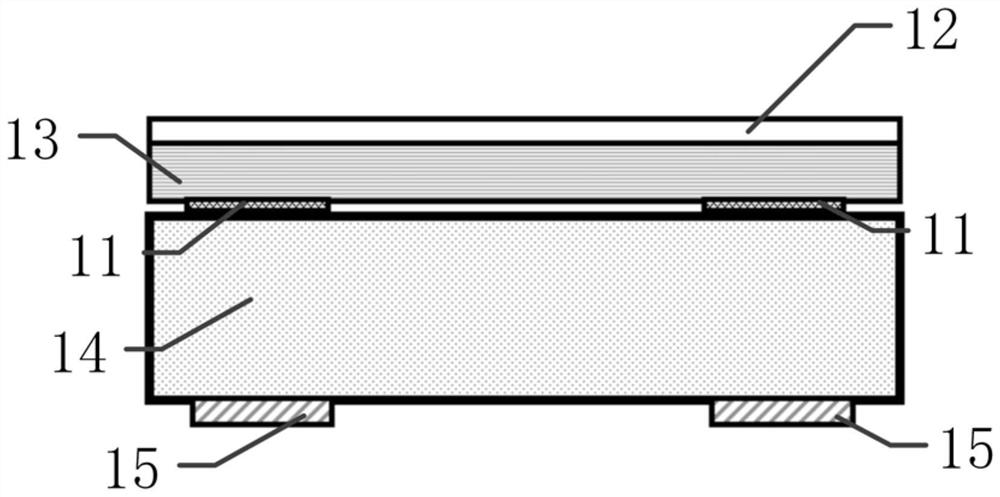

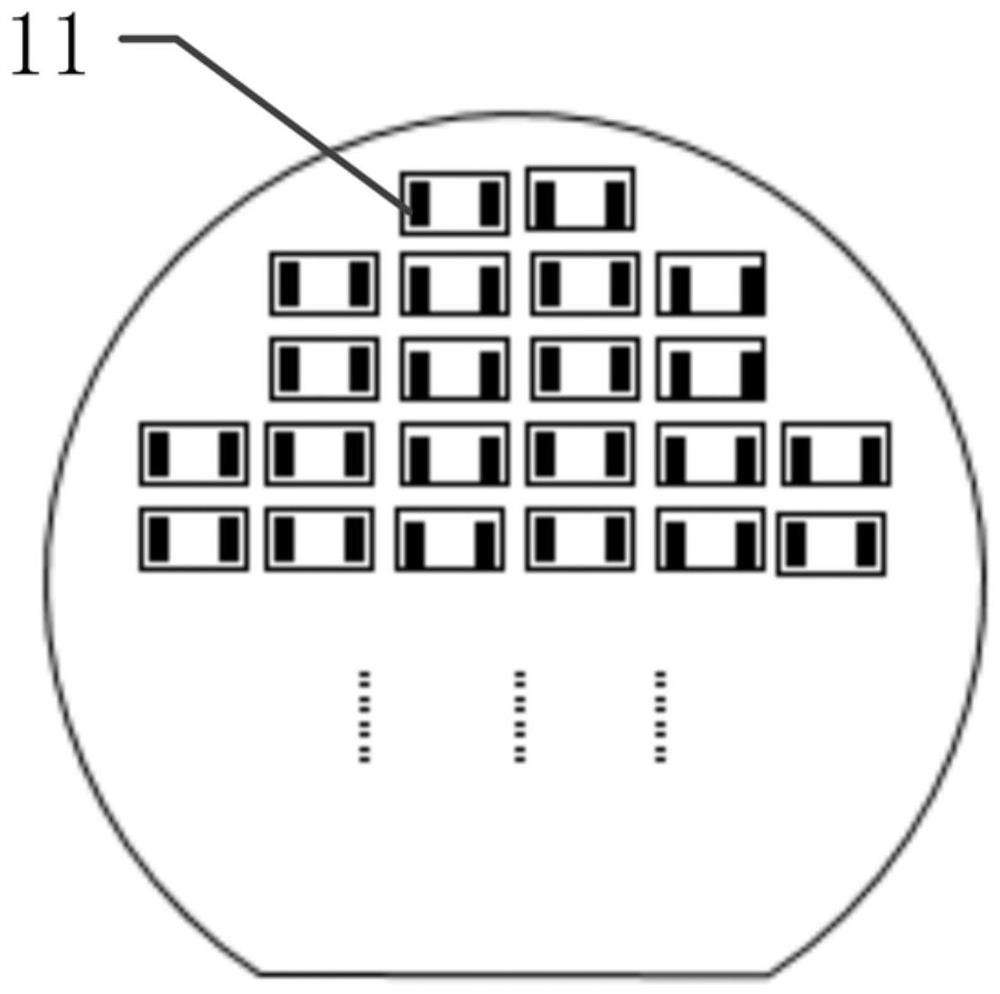

[0029] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0030] As mentioned in the background technology, the problem of poor light emitting effect of LED chips in the prior art is found by the inventors to be the most prominent in the field of Mini LED chips (LED chips with a size between 50 and 200 μm). The reason for this problem is that in order to solve the ink color consistency and improve the contrast, it is a common technical means to spray ink or black glue between the chips, but due to the capillary phenomenon, the climbing height of the ink or black glue on the side of the chip is different. The light emitted from the side of the chip will bring adverse effects. Based on this, this application proposes an LED chip and its preparation method and packaging method, which can be applied to the field of convent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com