Electrical cabinet with overheating protection structure

A technology for overheating protection and electrical cabinets, applied in the field of electrical cabinets, can solve the problems of cooling internal components and the difficulty of timely and effective discharge of high temperature in electrical cabinets, and achieves the effect of preventing moisture and having effective effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

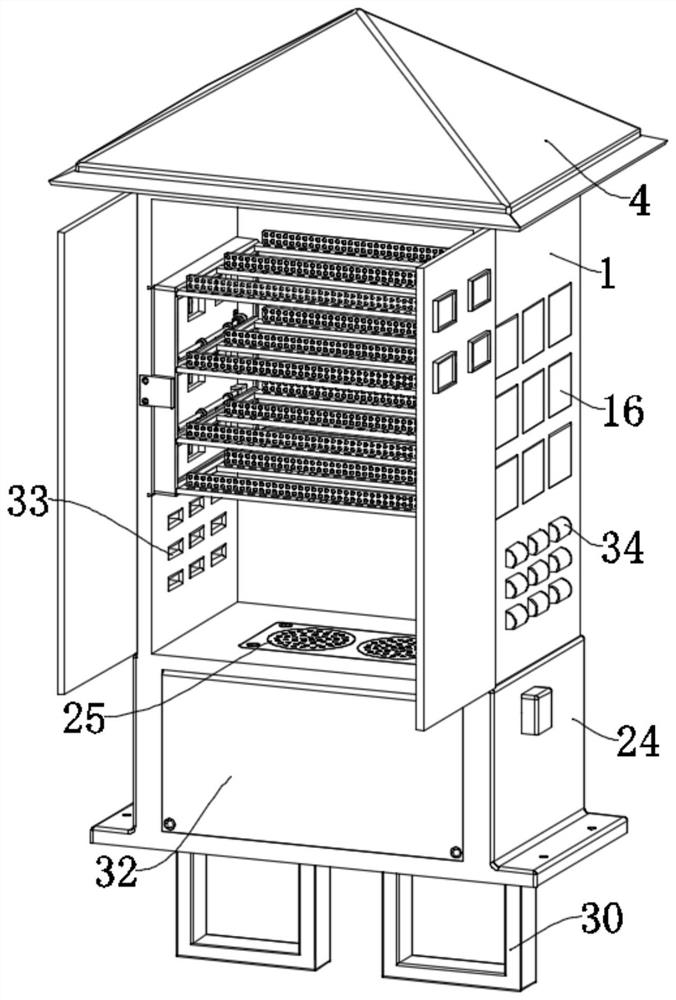

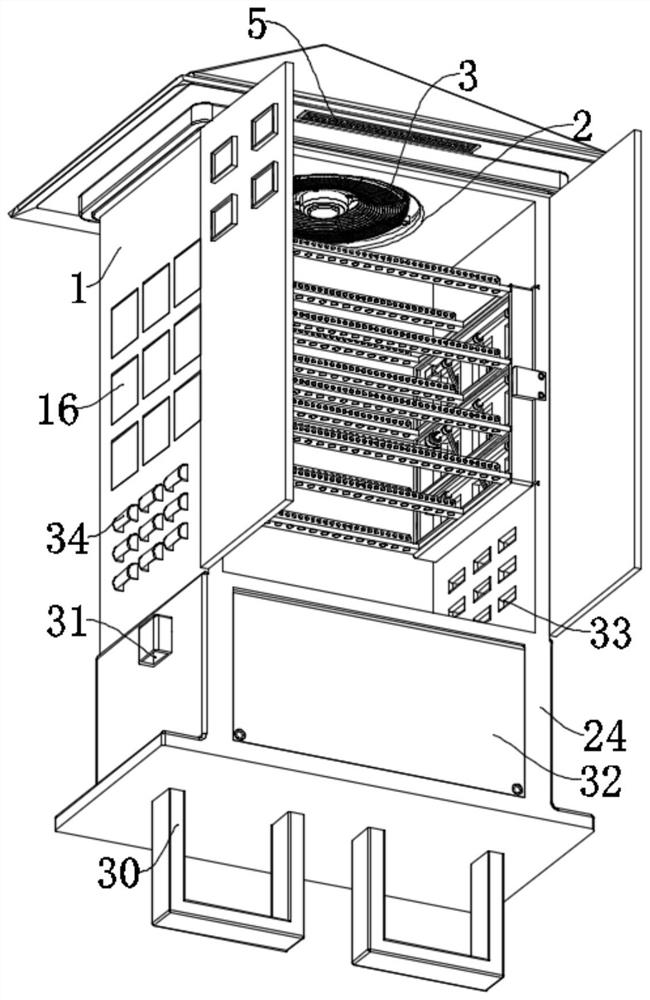

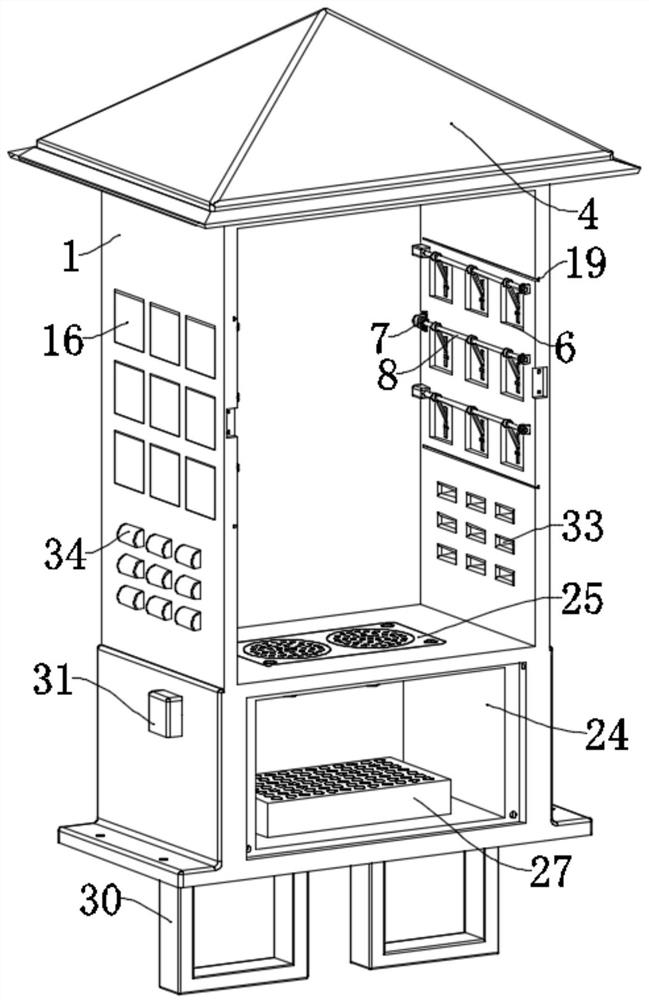

[0033] refer to Figure 1-8 , an electrical cabinet with an overheating protection structure, comprising an electrical cabinet 1, a first heat dissipation mechanism is provided on the top of the electrical cabinet 1, the first heat dissipation mechanism includes a top cover 4 arranged on the top of the electrical cabinet 1, and the top of the top cover 4 is pointed shape, the surface is inclined, which is convenient for outdoor use to block and disperse rainwater drainage, and the top cover 4 is provided with a cavity inside to accommodate gas, and the bottom of the electrical cabinet 1 is provided with air inlets 5 at the front and rear positions. The air inlet 5 enters the inside of the cavity when the external air enters, and the inside of the air inlet 5 is provided with a first dust-proof net, which prevents the dust from the outside from entering the cavity. The top of the electrical cabinet 1 is provided with a The installation groove 2 connected with the cavity, the in...

Embodiment 2

[0040] refer to Figure 1-8 , an electrical cabinet with an overheat protection structure, the bottom of the electrical cabinet 1 is fixed with a cold air box 24, the cold air box 24 is convenient for containing cold air, and a second heat dissipation fan is connected between the cold air box 24 and the electrical cabinet 1 26. The second heat dissipation fan 26 is convenient for sucking cold air into the interior of the cold air box 24. The top of the second heat dissipation fan 26 is located at the bottom of the inside of the electrical cabinet 1 and is provided with a filter plate 25. The filter plate 25 prevents components or routes from interfering with the second heat dissipation fan. 26 internal contacts, to prevent damage to the second cooling fan 26, the inside of the air-conditioning box 24 both sides is provided with an air chamber, and the air-conditioning box 24 both sides are provided with an air intake pipe 31 communicating with the air chamber, and the air intak...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap