Efficient and automatic frozen beef and mutton unfreezing device

A high-efficiency technology for beef and mutton, applied in the direction of freezing/cooling preservation of meat/fish, transportation and packaging, conveyors, etc., can solve the problems of loss of meat juice, low efficiency of thawing device, reduction of meat quality and taste, etc. Achieve the effect of guaranteeing freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] There are many ways to thaw frozen meat, including microwave thawing, steam thawing, and hot water thawing. It will adversely affect the quality of subsequent reprocessed products. Of course, if the traditional cooling water is used to thaw, although the quality of the meat can be guaranteed, the thawing efficiency is low, and the thawed meat needs to be fished by workers, which is inconvenient to operate and costs a lot of labor.

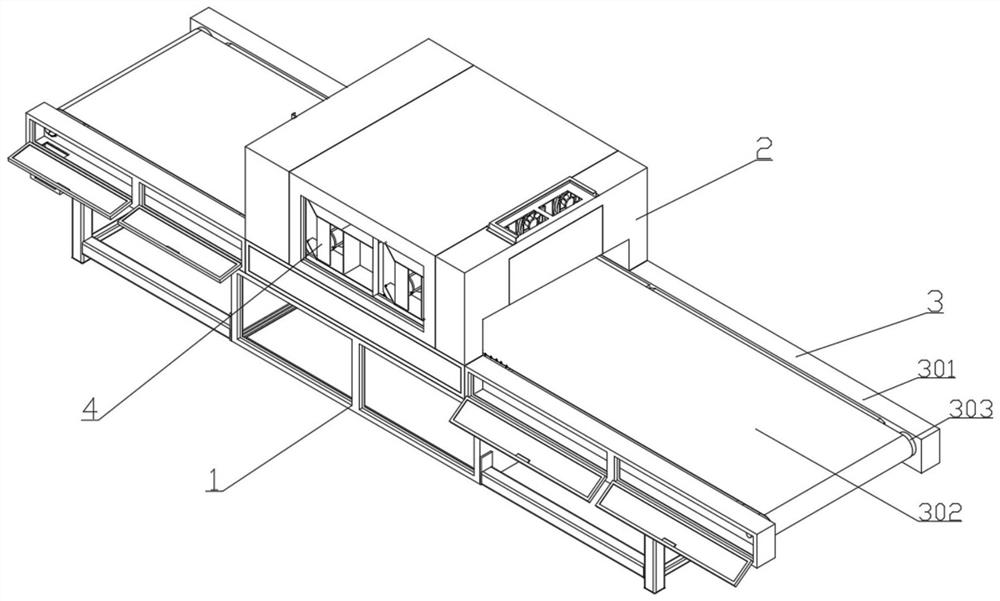

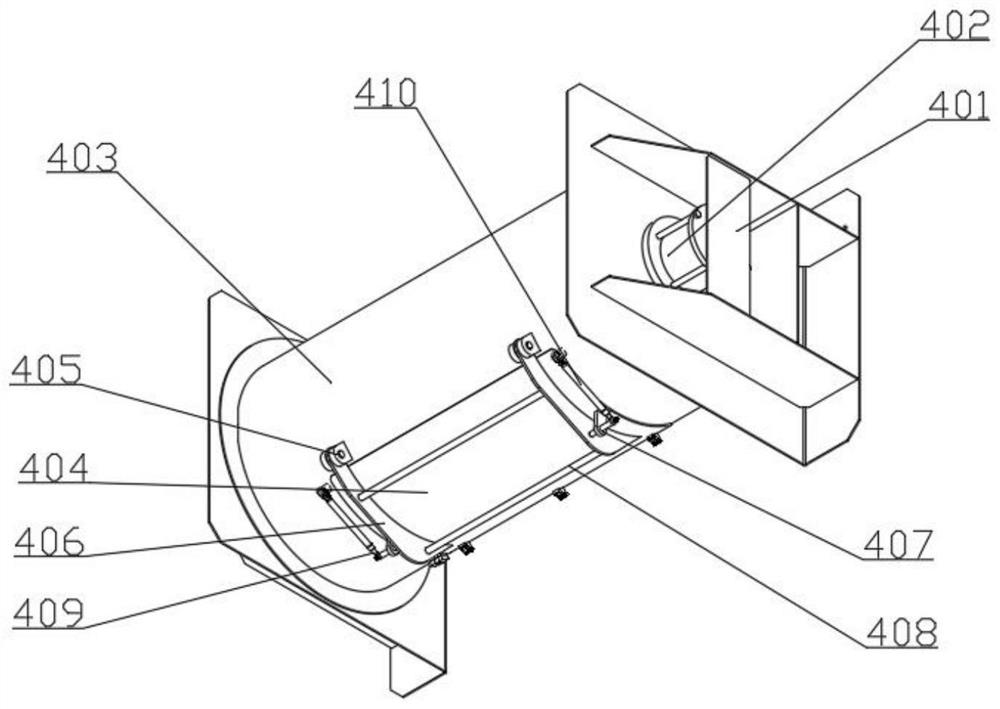

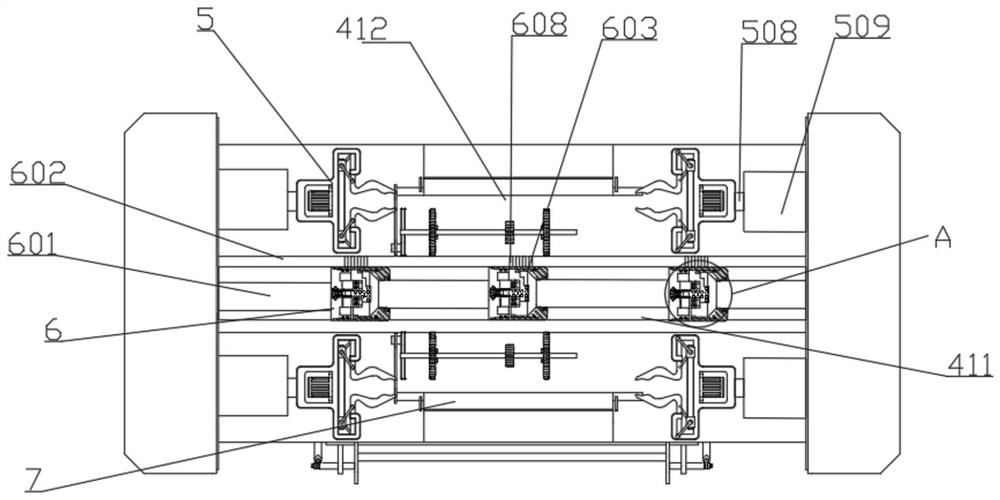

[0038] Such as Figure 1-6 As shown, the present invention provides a high-efficiency automatic frozen beef and mutton thawing device, comprising a support 1, a thawing part 2 and a transfer part 3, the transfer part 3 is placed on the top of the support 1, and the thawing part 2 is placed in the middle of the transfer part 3, A plurality of thawing drums 4 are placed in the thawing part 2, and the transfer part 3 includes a transfer bracket 301, a conveyor belt 302 and a plurality of transfer rollers 303, and a plurality of transfer roller...

Embodiment 2

[0043] There are many ways to thaw frozen meat, including microwave thawing, steam thawing, and hot water thawing. It will adversely affect the quality of subsequent reprocessed products. Of course, if the traditional cooling water is used to thaw, although the quality of the meat can be guaranteed, the thawing efficiency is low, and the thawed meat needs to be fished by workers, which is inconvenient to operate and costs a lot of labor.

[0044] Such as Figure 1-6 As shown, the present invention provides a high-efficiency automatic frozen beef and mutton thawing device, comprising a support 1, a thawing part 2 and a transfer part 3, the transfer part 3 is placed on the top of the support 1, and the thawing part 2 is placed in the middle of the transfer part 3, A plurality of thawing drums 4 are placed in the thawing part 2, and the transfer part 3 includes a transfer bracket 301, a conveyor belt 302 and a plurality of transfer rollers 303, and a plurality of transfer roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com