Multi-bar jacquard fabric with local sandwich effect

A sandwich and fabric technology, applied in knitting, warp knitting, textiles and papermaking, etc., can solve the problems of high production cost, poor fabric structure stability, high material scrap rate, etc., and achieve strong layering, strong structural stability, and breathability good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

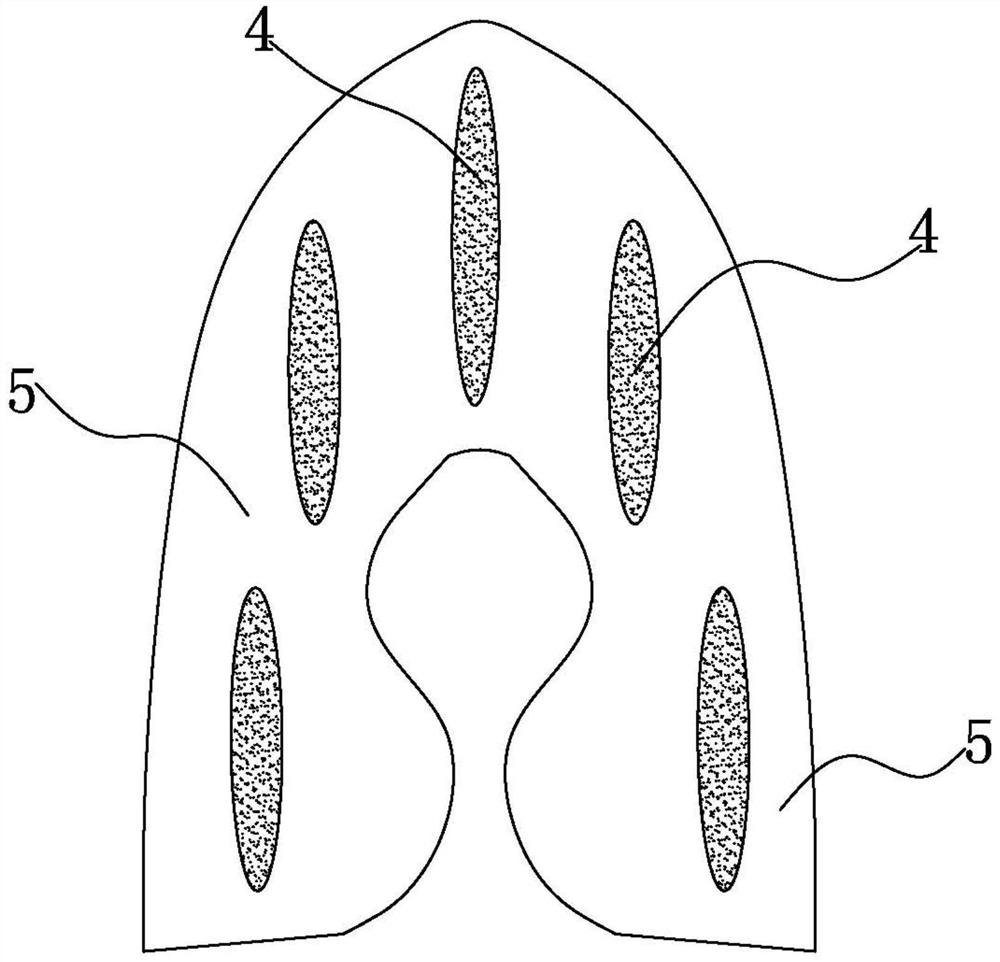

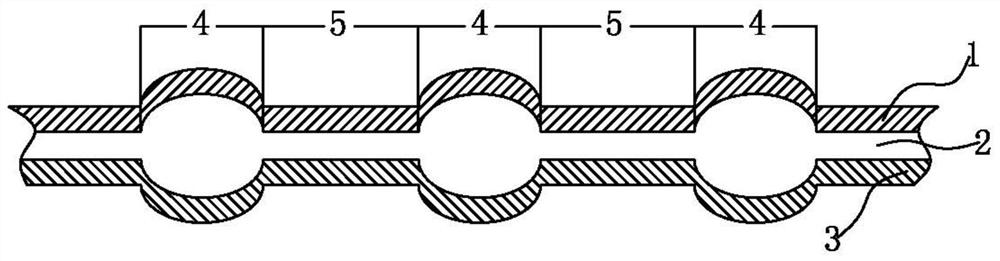

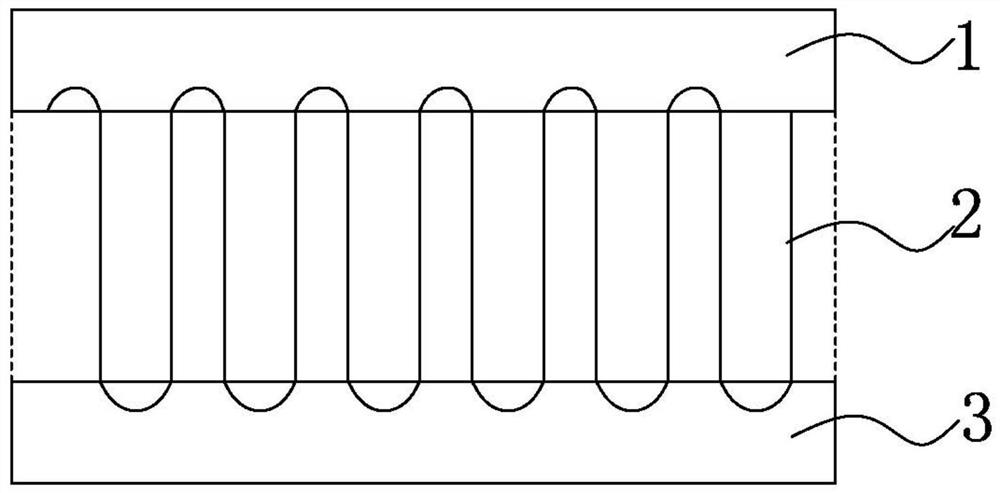

[0059] refer to Figure 1-2 , Figure 13 , figure 1 It is the front view of the multi-bar jacquard fabric with partial sandwich effect of the present invention; figure 2 It is a cross-sectional view of the multi-comb jacquard fabric with partial sandwich effect of the present invention; Figure 13 It is the physical picture of the multi-bar jacquard fabric with partial sandwich effect of the present invention.

[0060] This embodiment provides a multi-bar jacquard fabric with a local sandwich effect, comprising a fabric body woven by a double-needle bed warp knitting machine with at least one jacquard bar, the fabric body comprising a surface layer 1, The bottom layer 3, the wool layer 2 woven between the surface layer 1 and the bottom layer 3, the wool layer 2 is woven by at least one jacquard bar laying yarn.

[0061] refer to image 3 , 7 , image 3 Sectional view of the first weaving region of the multibar jacquard fabric with partial sandwich effect according to ...

Embodiment 2

[0064] refer to Figure 1-2 , Figure 13 , figure 1 It is the front view of the multi-bar jacquard fabric with partial sandwich effect of the present invention; figure 2 It is a cross-sectional view of the multi-comb jacquard fabric with partial sandwich effect of the present invention; Figure 13 It is the physical picture of the multi-bar jacquard fabric with partial sandwich effect of the present invention.

[0065] This embodiment provides a multi-bar jacquard fabric with a local sandwich effect, comprising a fabric body woven by a double-needle bed warp knitting machine with at least one jacquard bar, the fabric body comprising a surface layer 1, The bottom layer 3, the wool layer 2 woven between the surface layer 1 and the bottom layer 3, the wool layer 2 is woven by at least one jacquard bar laying yarn.

[0066] refer to Figure 4 , 8 , Figure 4 Sectional view of the first weaving region of the multibar jacquard fabric with partial sandwich effect according to...

Embodiment 3

[0069] refer to Figure 1-2 , Figure 13 , figure 1 It is the front view of the multi-bar jacquard fabric with partial sandwich effect of the present invention; figure 2 It is a cross-sectional view of the multi-comb jacquard fabric with partial sandwich effect of the present invention; Figure 13 It is the physical picture of the multi-bar jacquard fabric with partial sandwich effect of the present invention.

[0070] This embodiment provides a multi-bar jacquard fabric with a local sandwich effect, comprising a fabric body woven by a double-needle bed warp knitting machine with at least one jacquard bar, the fabric body comprising a surface layer 1, The bottom layer 3, the wool layer 2 woven between the surface layer 1 and the bottom layer 3, the wool layer 2 is woven by at least one jacquard bar laying yarn.

[0071] refer to Figure 5 , 9 , Figure 5 Sectional view of the first weaving region of the multibar jacquard fabric with partial sandwich effect according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com