Railway track cleaning robot

A technology for cleaning robots and railway tracks, applied in the field of track cleaning, can solve the problems of reducing the efficiency of cleaning rails and worker fatigue, and achieve the effect of avoiding danger and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

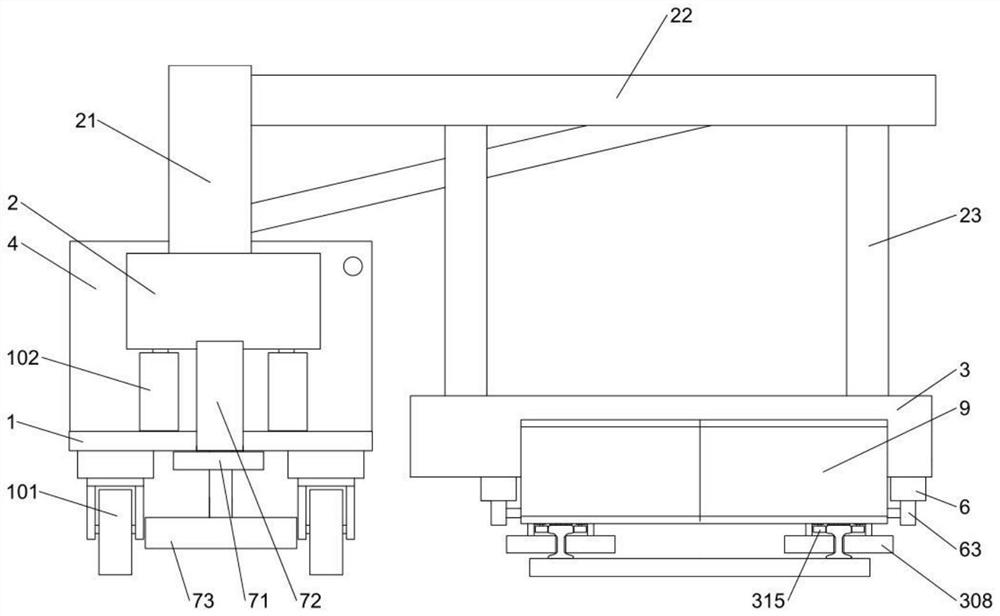

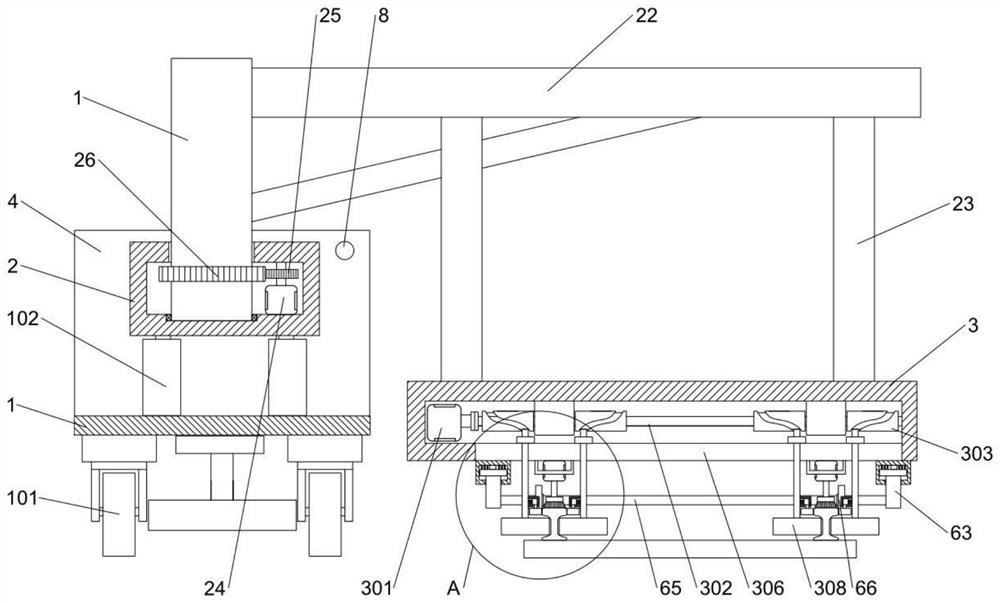

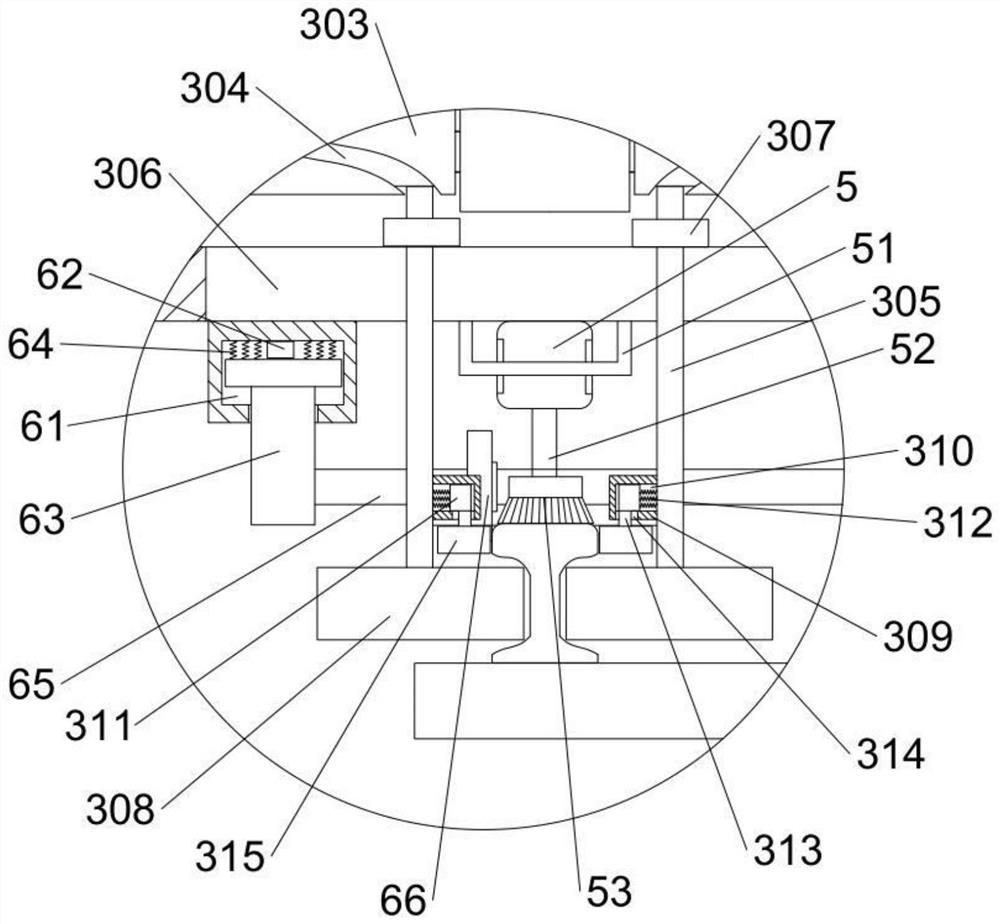

[0029] Such as Figure 1 to Figure 5 As shown, the present invention provides a railway track cleaning robot, comprising a chassis 1, a running mechanism, a support box 2, a connecting column 21, an angle adjustment mechanism, a first cleaning mechanism and a control box 4; the running mechanism is arranged under the chassis 1; The supporting box 2 is arranged on the chassis 1 by a lifting mechanism; the connecting column 21 is vertically arranged in the supporting box 2, and its upper end extends to the outside of the supporting box 2 and is vertically fixed with a connecting rod 22, and the bottom of the connecting rod 22 is fixed with a horizontal The installed installation box 3; the angle adjustment mechanism is arranged in the support box 2 and is connected with the lower end of the connecting column 21, and is used to adjust the circumferential rotation angle of the connecting column 21; the first cleaning mechanism is arranged on the bottom of the installation box 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com