Floor tile laying equipment capable of preventing concrete drying for building decoration

A technology for concrete and floor tiles, which is used in construction, building structure, clay preparation devices, etc., can solve the problems of easy drying of concrete and long time, and achieve the effect of improving the laying effect, preventing the drying of concrete and ensuring the adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

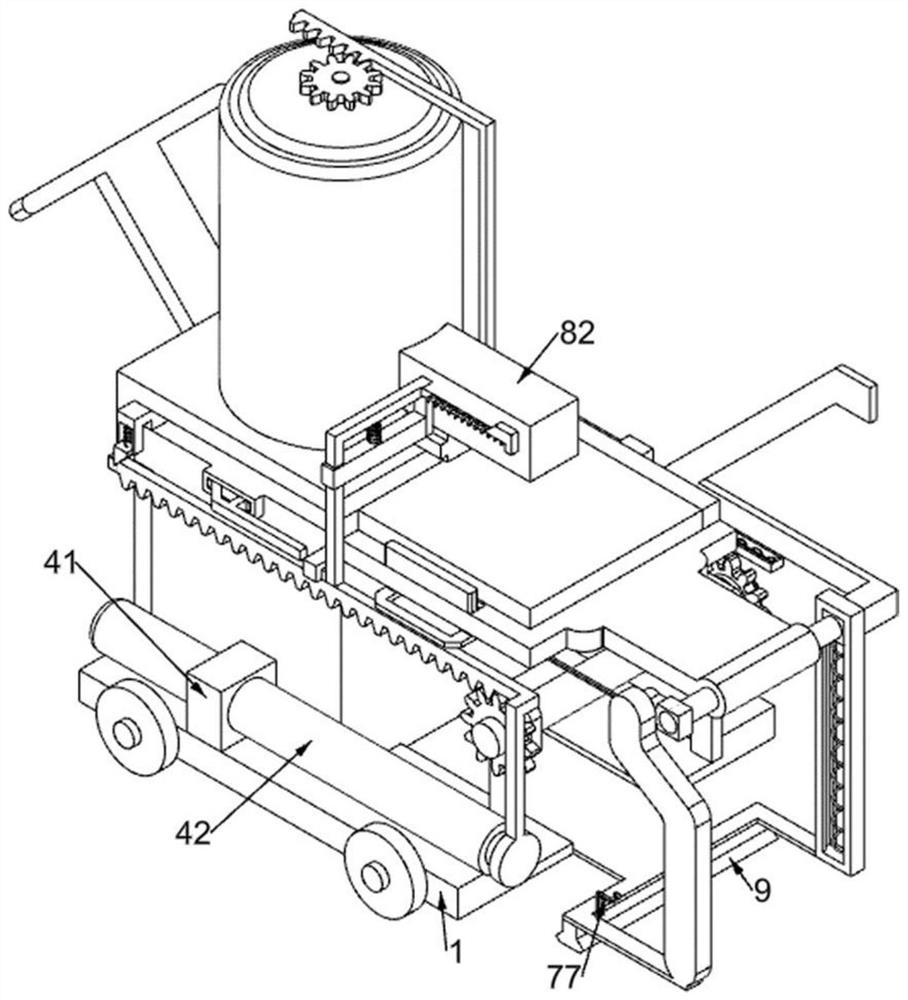

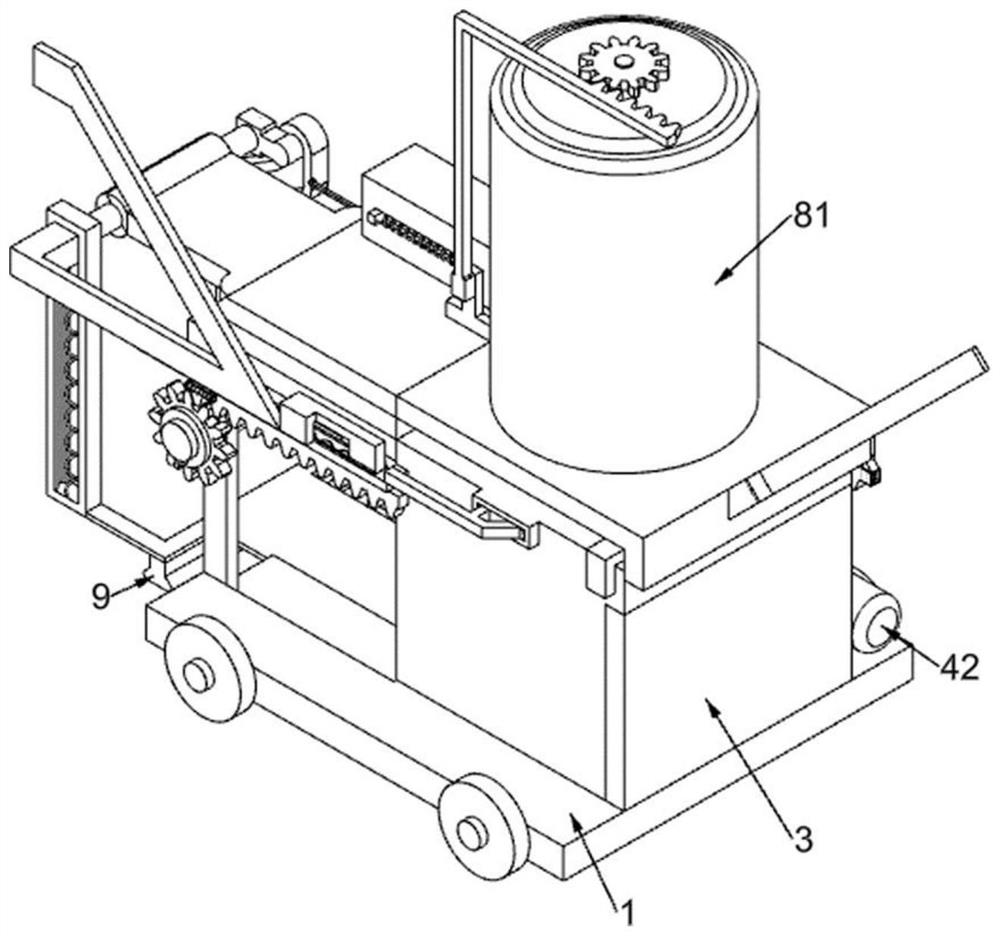

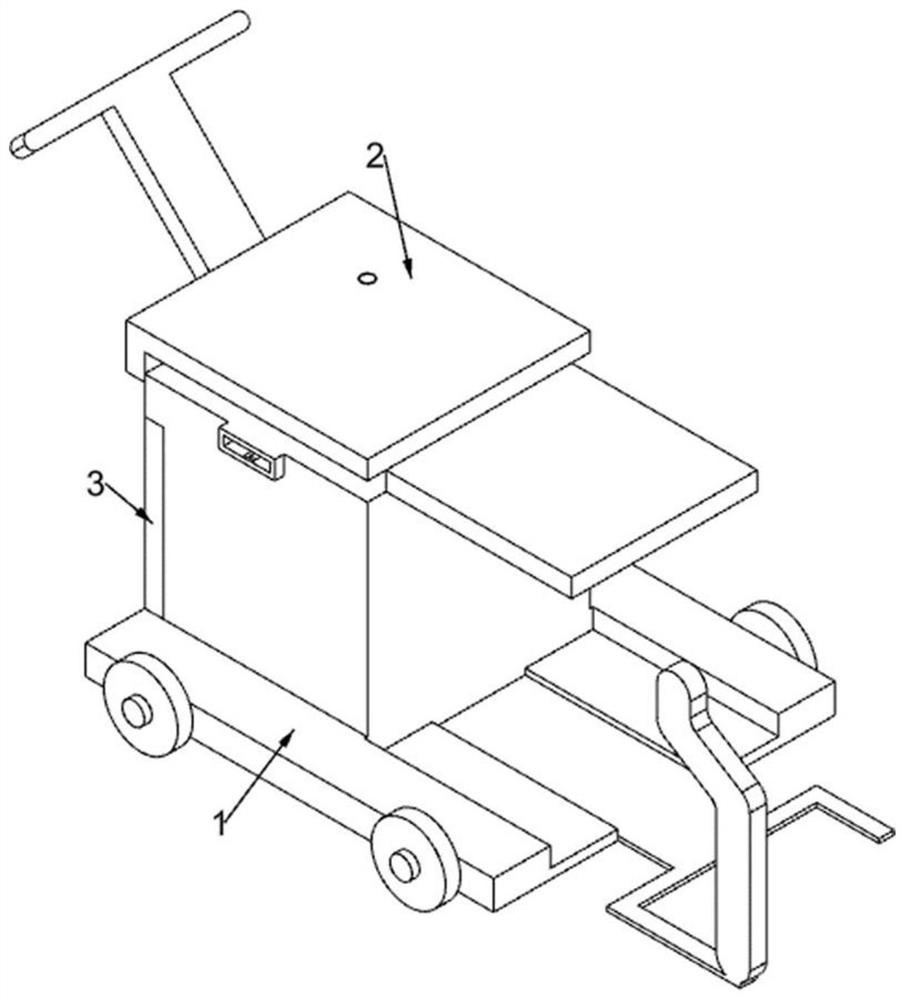

[0038] A floor tile laying equipment that can prevent concrete from drying out for building decoration, such as Figure 1-11 As shown, it includes a sliding loading vehicle 1, a slotted push frame 2, a cover plate 3, a driving mechanism 4, a pushing mechanism 5, a turning brick laying mechanism 6, and a clamping reset mechanism 7. The sliding loading vehicle 1 is rectangular. Distributed with four rollers, the top of the sliding loading car 1 is fixed with a slotted push frame 2, and the slotted push frame 2 is connected with a cover plate 3 through a hinge, and the cover plate 3 is connected with the slotted push frame 2 and the sliding loading plate The car 1 contacts, and the sliding loading car 1 is provided with a driving mechanism 4 for driving the operation of the equipment, and the slotted push frame 2 is provided with a pushing mechanism 5 for pushing the floor tiles inside the slotted pushing frame 2, and the sliding loading car 1 is provided with an overturning bric...

Embodiment 2

[0048] On the basis of Example 1, such as Figure 12 As shown, it also includes a discharge rotating mechanism 8, which is used to add concrete to the surface of the floor tiles on the turnover plate 63. , rectangular cavity block 82, baffle plate 83, ninth return spring 84, special-shaped push block 85, wedge-shaped slide bar 86, tenth return spring 87, eleventh return spring 88, L-shaped rack frame 89, third gear 810 and turbine rod 811, the outer top of the slotted push frame 2 is fixedly connected with a cylinder 81, the cylinder 81 is cylindrical, and its interior is a cavity structure, and the outer wall of the cylinder 81 is connected with a rectangular cavity block 82, the rectangular cavity block 82 The inside of cavity block 82 is a cavity structure, and its bottom has a rectangular hole. The bottom of rectangular cavity block 82 is slidably connected with baffle plate 83. The ninth back-moving spring 84 that plate 83 resets, the rectangular cavity block 82 is slida...

Embodiment 3

[0051] On the basis of Example 2, such as figure 1 As shown, a flattening block 9 is also included, and the bottom of the sliding loading vehicle 1 is fixedly connected with the flattening block 9, and the flattening block 9 is located below the turning plate 63.

[0052] Then manually push the sliding pallet loading vehicle 1 and its upper device to continue to move forward. The laid floor tiles can be flattened by the flattening block 9. Finally, the electric push rod 42 is manually controlled to stop operation. Repeat the above operations to use the equipment to lay floor tiles again. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com