Fault simulation test system for bullet train wheel set assembly

A fault simulation and test system technology, applied in the field of rail vehicles, can solve problems such as inability to simulate tests, inability to simulate natural cooling air of motor vehicles, etc., and achieve the effects of improving safety and operation stability, high test efficiency, and convenient installation and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

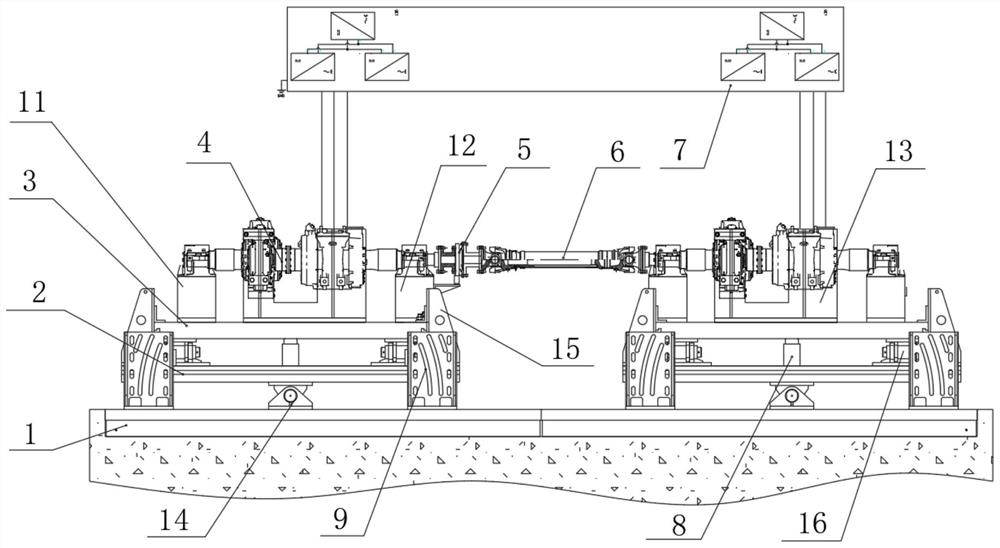

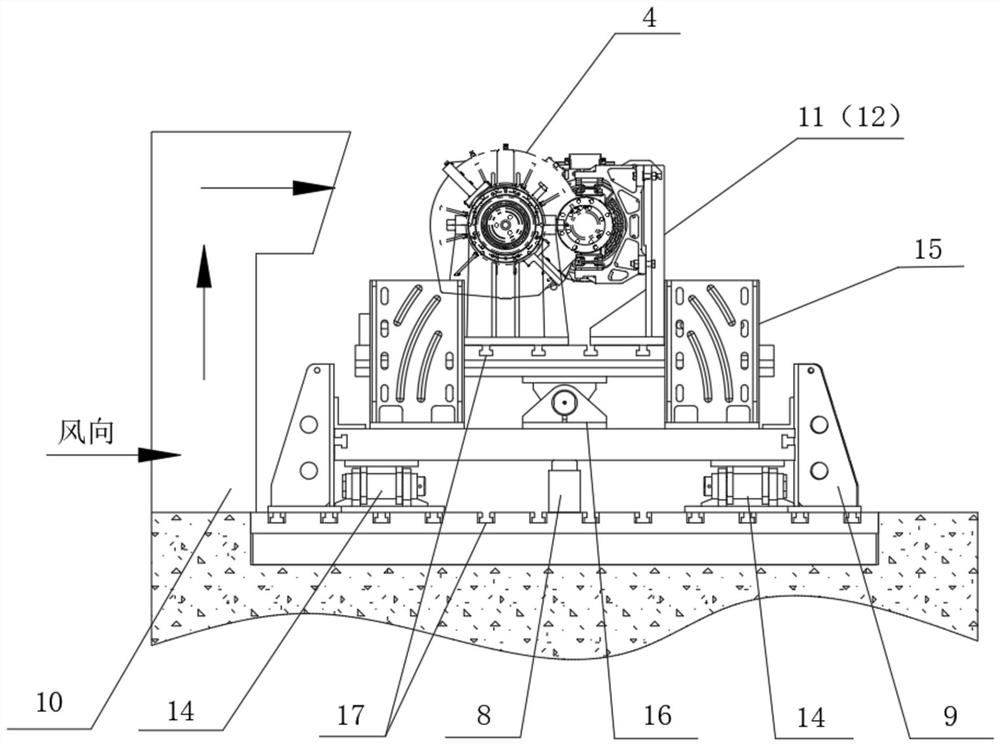

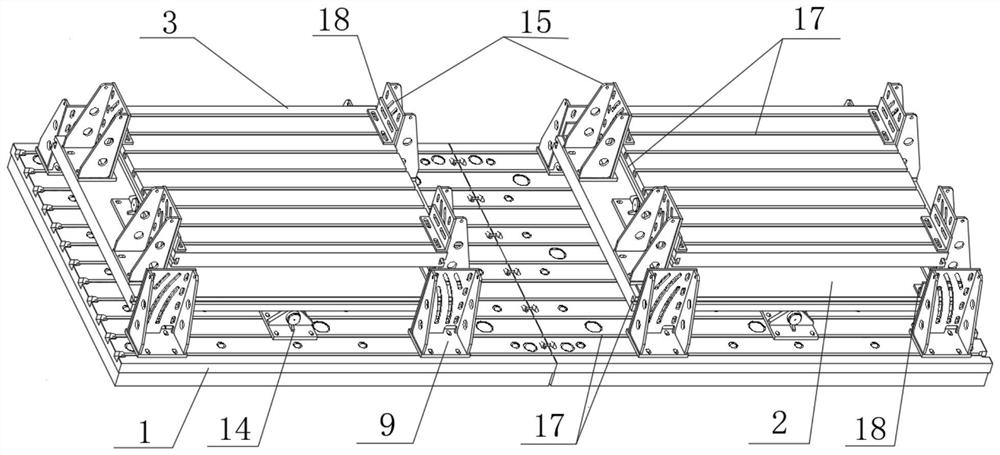

[0033] Such as Figure 1 to Figure 5 As shown, the fault simulation test system for the wheel set assembly of the present invention includes: a test platform 1 and a motor drive assembly 7 . Two sets of simulation devices with the same structure are arranged side by side on the test platform 1 , two sets of moving wheel pair assemblies 4 are fixedly connected to the two sets of simulation devices respectively, and the two sets of moving wheel pair assemblies 4 are connected through a coupling 6 . The simulator can simulate one of the horizontal working conditions, superelevation working conditions and ramp working conditions alone, or simultaneously simulate level + superelevation, level + ramp, superelevation + ramp, level + superelevation + ramp and other freely combined working condition tests, various working condition comparative simulation tests can also be carried out to meet the test requirements of the moving wheel pair assembly 4. The two sets of moving wheel pair a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com