Method and system for automatically placing orders and receiving orders under modular BOM

A modular and automatic technology, applied in manufacturing computing systems, instruments, business and other directions, can solve the problems of prolonged order delivery time, information asymmetry, and high error rate, to reduce repeated creation and operation, reduce repeated selection, and satisfy The effect of fast ordering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

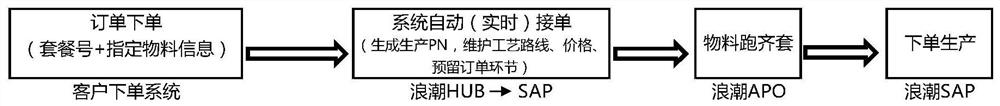

[0041] Embodiment 1 of the present invention proposes a method for automatically placing and receiving orders under a modularized BOM, such as figure 1 A flow chart of a method for automatically placing an order and receiving an order under a modularized BOM in Embodiment 1 of the present invention is given; the present invention proposes a JDM mode (Joint Development, Join Design Manufacture) to automatically place an order and realize the delivery system Method: The customer system places an order with the package number and specified material information. The system automatically and in real time receives the order, generates the production PN, maintains the process route, price, reserved order, and complete set of materials, and transmits the order for production. Customer orders are automatically placed, which not only reduces the repeated creation and operation of each link in the package BOM generation and each position, but also satisfies the need for fast order placeme...

Embodiment 2

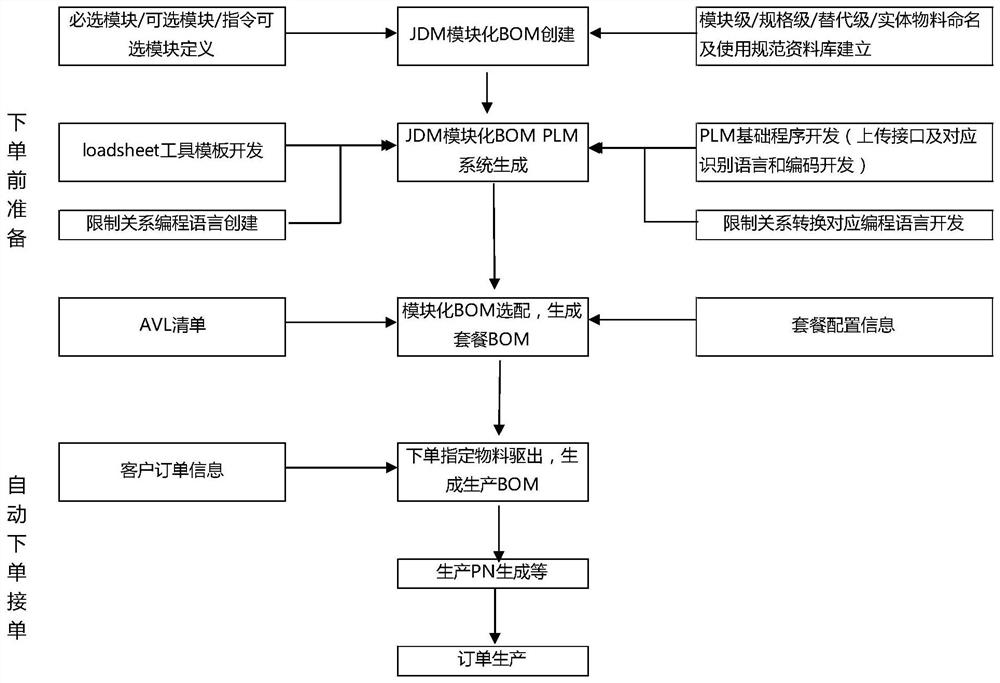

[0042]Before placing an order in the system, first prepare for the order. Such as figure 2 It is the overall flow chart of the preparation before placing an order and the automatic order receiving under the modularized BOM in Embodiment 2 of the present invention;

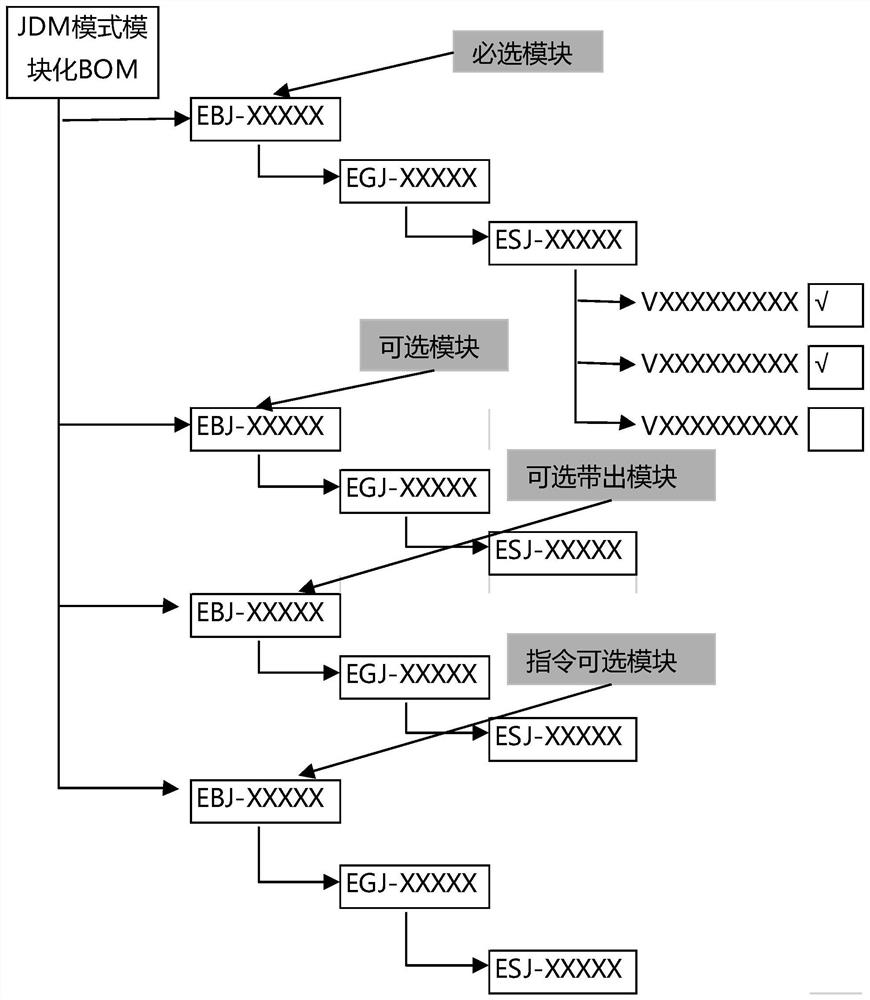

[0043] First, create the JDM modular BOM architecture based on the product architecture as the data source for the entire product; second, create the corresponding JDM BOM to the PLM system (i.e., product life cycle management) for data matching; third, use the AVL list (i.e. the list of qualified suppliers) and package information to select and match JDM BOM, generate package BOM, and transfer to SAP system; finally, transmit order information with real-time received customer system, correspond to package information in Inspur SAP, and drive out package The customer specifies the material in the BOM, generates the production BOM, and generates the production PN (that is, the product number) in the SAP system, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com