Stamping device suitable for machining of different sizes and used for automobile parts

A technology of auto parts and stamping devices, which is applied in the field of auto parts processing, can solve problems such as cumbersome operation steps and automatic mold limit, and achieve the effect of improving the stability of the limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

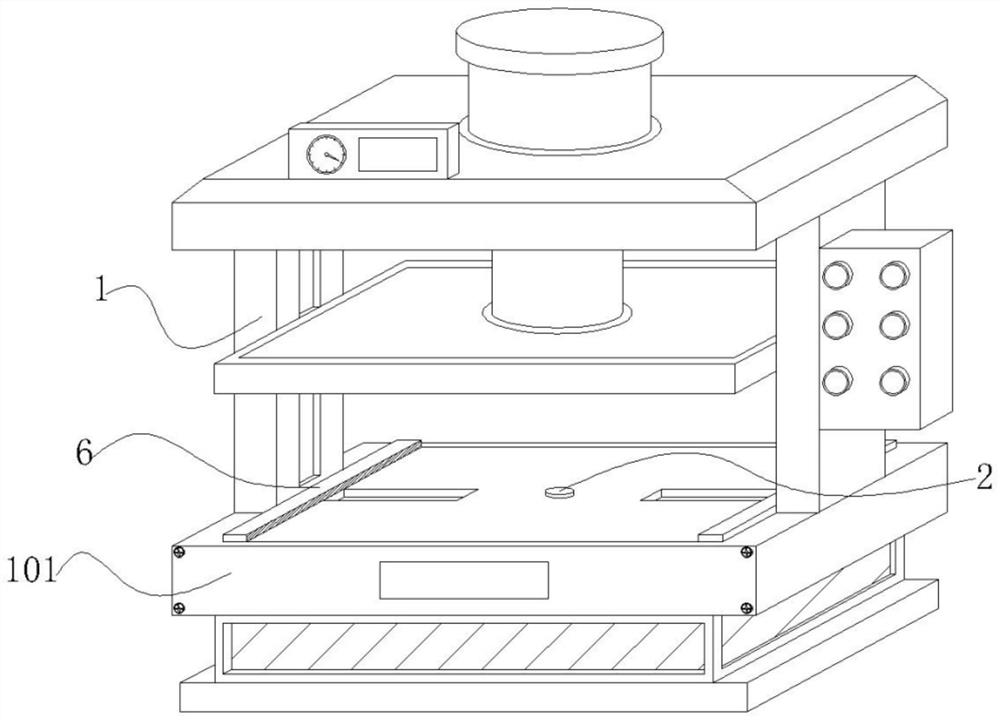

[0029] Embodiment 1: A stamping device suitable for processing auto parts of different sizes, including a stamping machine 1, a base 101 is installed on the inside of the stamping machine 1, and a transmission mechanism that can automatically limit the position is provided on the inside of the base 101;

[0030] Among them: the two sides of the upper end of the base 101 are embedded with grooves, and the transmission mechanism slides inside the groove. When the mold is placed on the inner side of the base 101, the transmission mechanism will limit the mold according to the size of the mold by using the mold pressure, which is suitable for different sizes. mold;

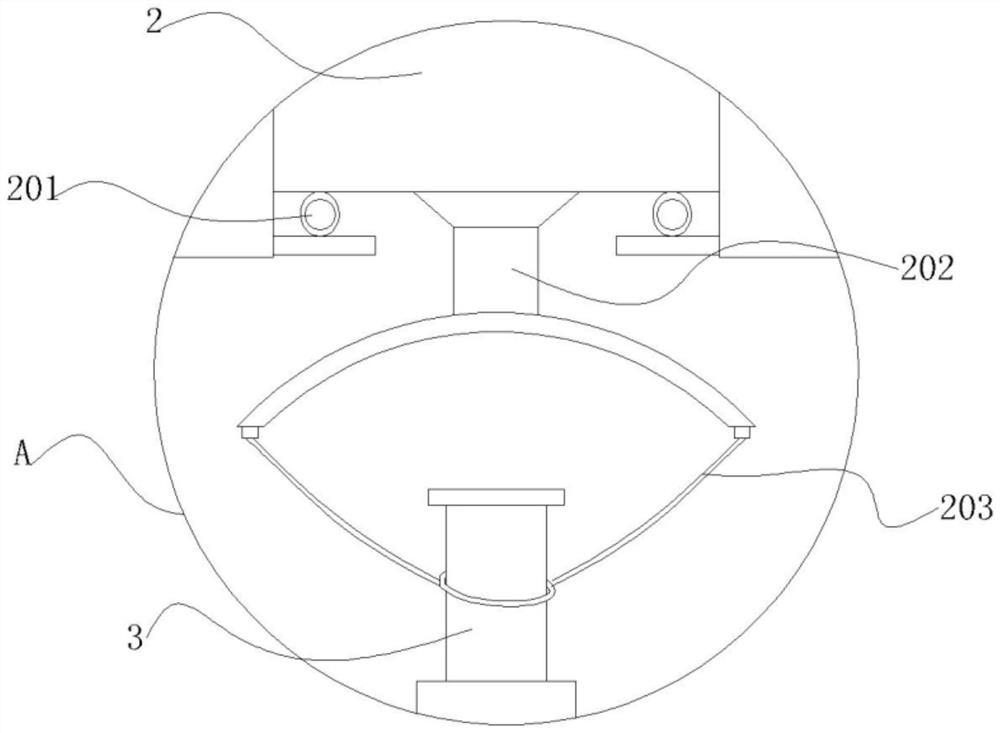

[0031] The transmission mechanism includes a briquetting block 2, a first air bag 201, a bracket 202, a stay cord 203 and a rotating shaft 3. The briquetting block 2 slides on the inside of the base 101, the first air bag 201 expands and contracts on both sides of the lower end of the briquetting block 2, and the brack...

Embodiment 2

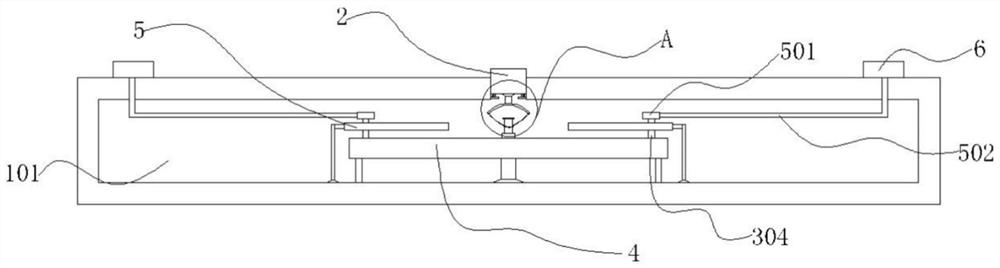

[0039] Embodiment 2: with reference to instruction manual Figure 4 and 5 It can be seen that the difference between Embodiment 2 and Embodiment 1 is that the transmission mechanism includes a bearing 301, a connecting rod 302, a gear 303, a snap ring 304, a circular ring 4, a tooth piece 401, a track 5, a collar 501, and a connecting frame 502 and the second air bag 6, the bearing 301 is installed on the outside of the rotating shaft 3, the connecting rod 302 and the gear 303 rotate on one side of the bearing 301 in turn, the snap ring 304 rotates on one side of the gear 303, and the ring 4 and the gear piece 401 rotate and insert Fitting on the outside of the gear 303, the track 5 is fixed inside the base 101, the collar 501 slides on the outside of the snap ring 304, and the connecting frame 502 and the second airbag 6 are installed on one side of the collar 501 in turn;

[0040] The snap ring 304 slides through the rail 5 and the inner side of the collar 501 in turn, the ...

Embodiment 3

[0047] Embodiment 3: with reference to instruction manual Figure 6 It can be seen that the difference between Embodiment 3 and Embodiments 1 and 2 is that the two sides of the second airbag 6 are inlaid with bumps 601, the back of the second airbag 6 is penetrated with a negative pressure valve 602 installed, and the front of the second airbag 6 Mosaic limited layer 603;

[0048] The thickness of the limiting layer 603 is 1-2 cm less than the second airbag 6 as a whole, and one side of the limiting layer 603 is attached to the second airbag 6;

[0049] Wherein: when the second airbag 6 is extruded to both sides of the mold according to the second embodiment, the bump 601 is depressed to the inside of the second airbag 6 by the extrusion of the mold, and the negative pressure valve 602 is used to form a negative pressure state inside the second airbag 6 , and furthermore, the limit layer 603 is deformed as a whole, and the limit layer 603 is concave, so as to assist the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com