Automatic baffle pressing type steel belt cooling material conveyor

A baffle, cooling technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large maintenance workload, poor reliability and stability of continuous operation, waste of resources, etc., to reduce daily maintenance. The workload, daily maintenance workload is small, and the effect of eliminating the waste of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

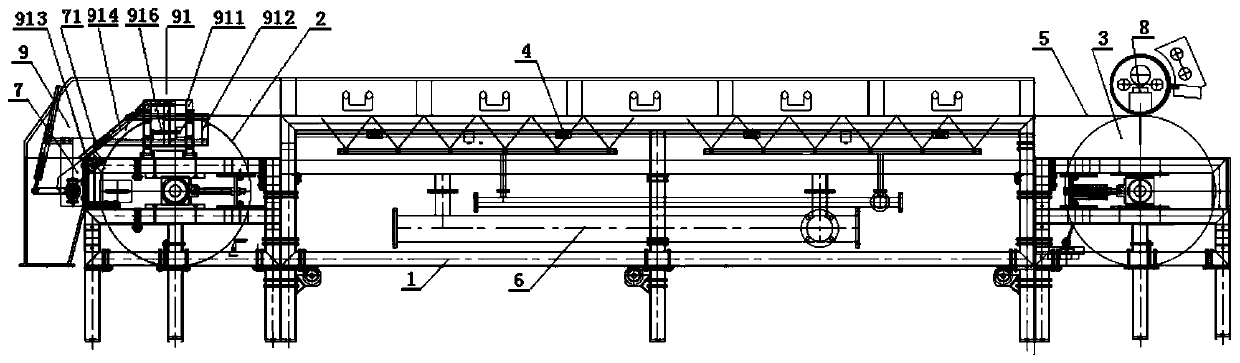

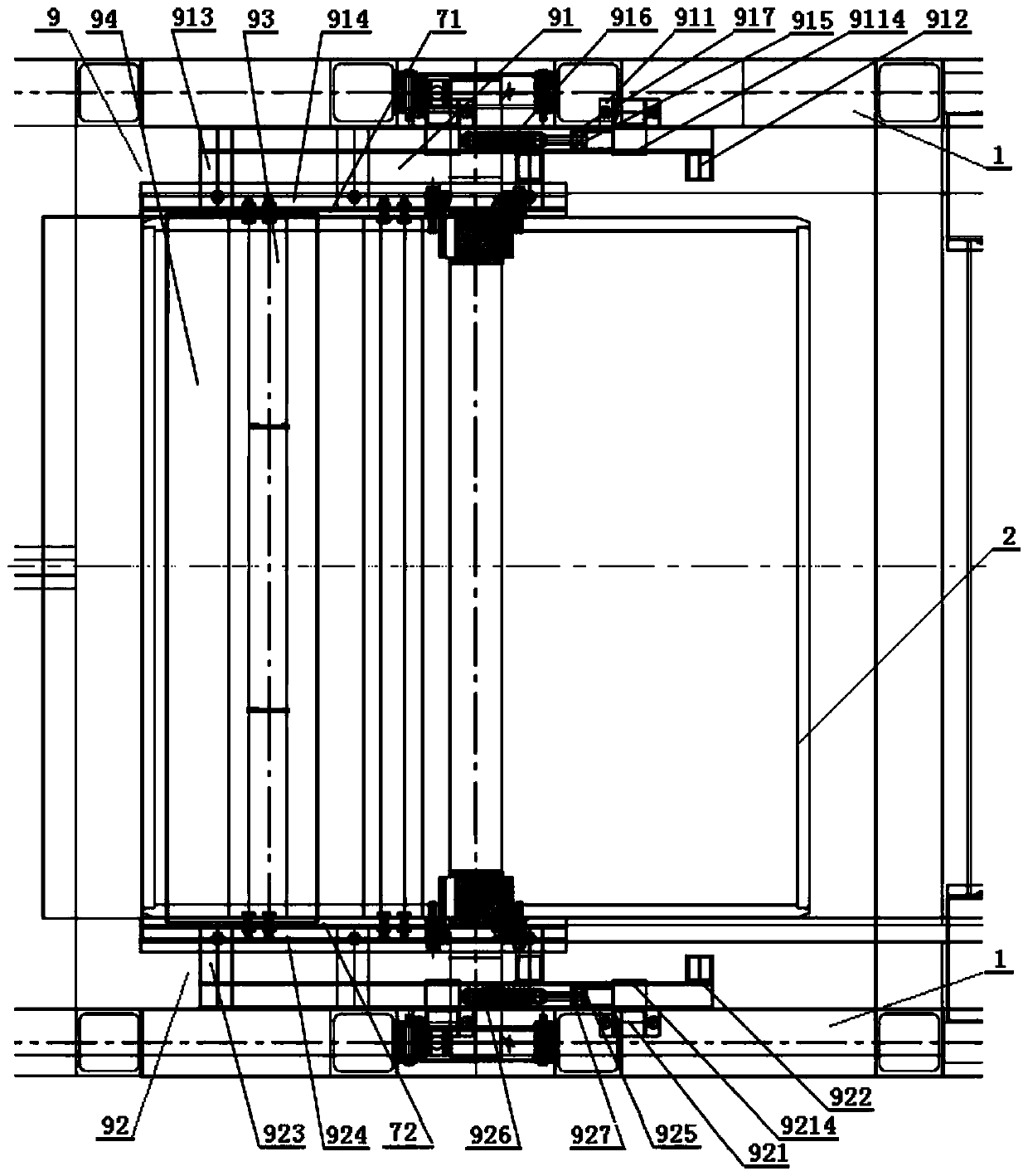

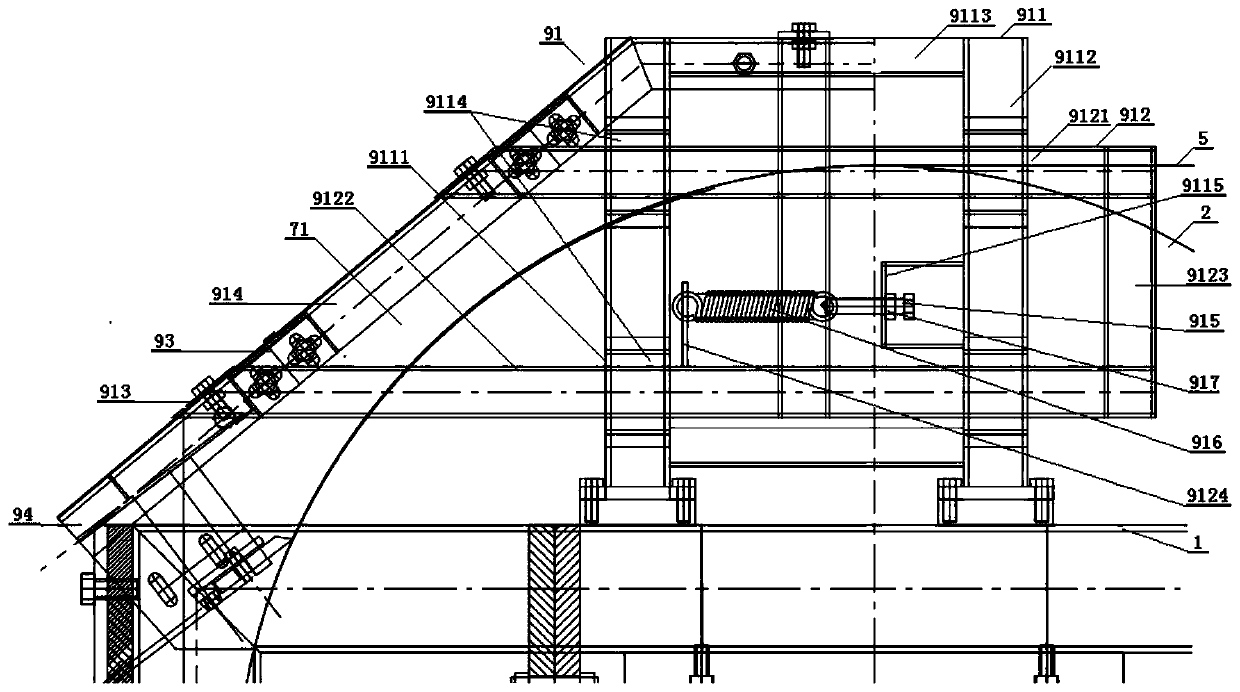

[0035] exist figure 1 , figure 2 and image 3 Among them, the automatic compression type steel belt cooling material conveyor of the material baffle plate of the present invention, the main body includes a frame 1, and the main driving drum 2 and the driven tensioning drum 3 respectively fixed at the front and rear ends of the frame are arranged on The steel belt carrying platform 4 between the left and right side frames of the frame, the material transport steel belt 5 arranged in a closed loop between the main driving drum 2 and the driven tensioning drum 3, and the water cooling cooling mechanism arranged under the steel belt carrying platform 4 6. Set on the side of the main driving drum 2, including the right baffle plate 71, the left baffle plate 72, the unloading scraper, the unloading mechanism 7 of the unloading hopper, and the unloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com