Use method of electrical equipment maintenance system

A technology for power equipment and utility poles, which is applied in the direction of lifting equipment safety devices, lifting devices, etc., to achieve the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

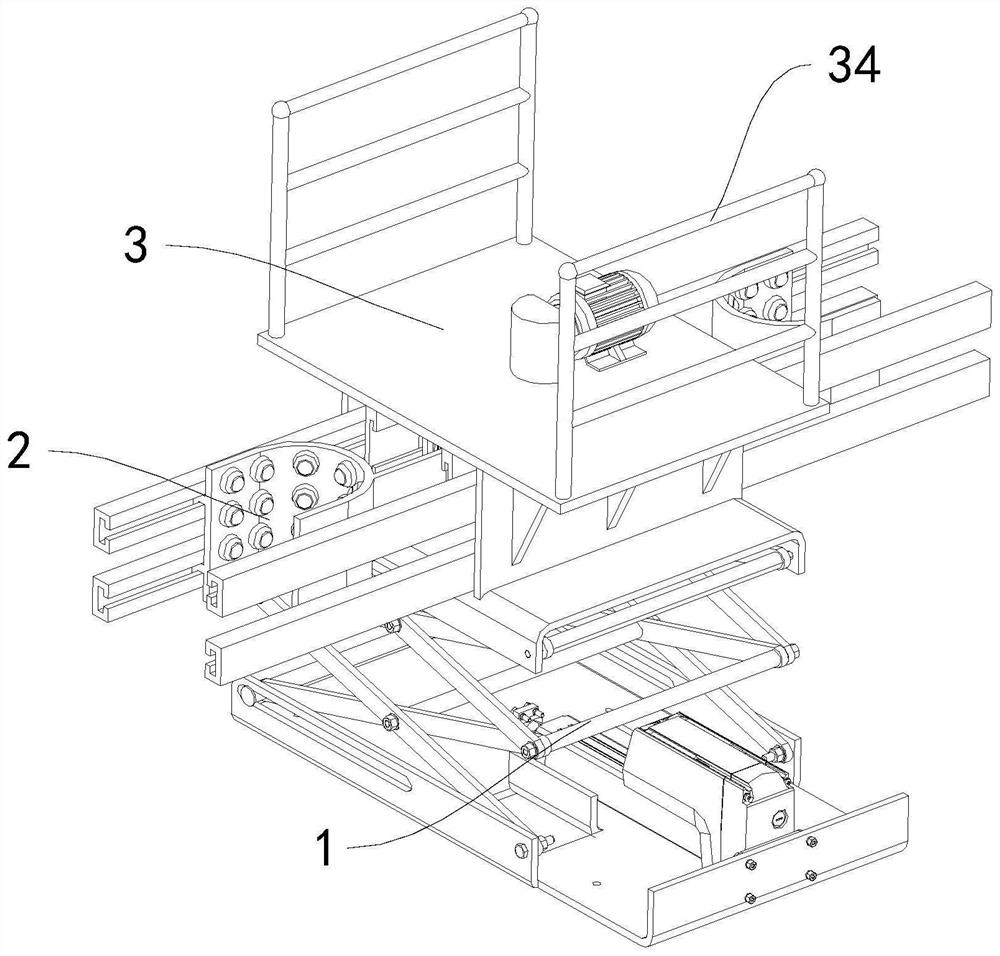

[0043] A method for using a lifting type power equipment maintenance device, comprising the following steps:

Embodiment 2

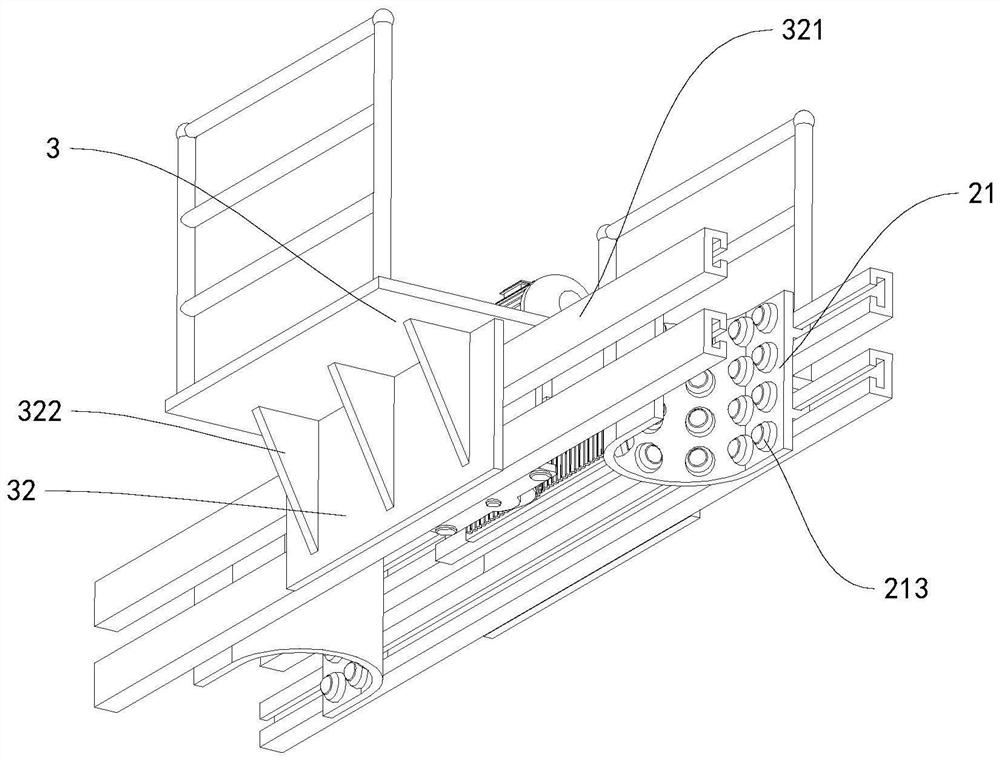

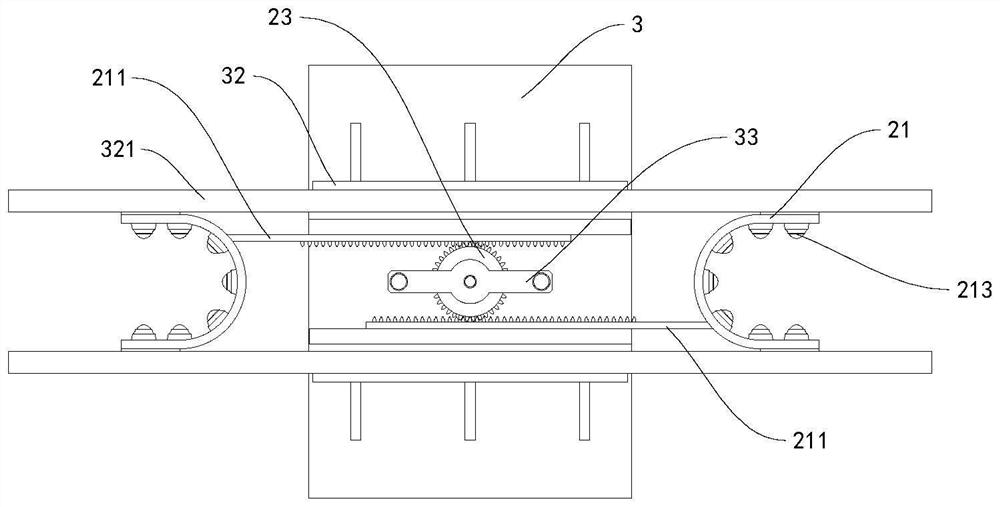

[0044] S2: Start the limit motor 22, drive the limit gear shaft 23 by the limit motor 22 provided, utilize the limit gear shaft 23 to drive the telescopic racks 211 on the two U-shaped limit grooves 21, so that the two U-shaped The limit groove 21 moves laterally to both sides synchronously. At this time, the U-shaped limit groove 21 moves to the two utility poles under the push of the telescopic rack 211, and makes the contact rolling ball 213 closely contact with the utility poles. The U-shaped limiting grooves 21 on both sides cooperate with the utility poles to realize the positioning of the equipment.

[0045] S3: The operator stands on the operation platform 3 and binds the safety belt on the body to the protective railing 34 .

[0046]S4: Start the lifting drive electric cylinder 13, and drive the bottom connecting reinforcing rod 15 to move laterally through the operation of the lifting driving electric cylinder 13, so that the lifting driving rod 14 connects with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com