Double-compensation interruption type anti-gravity pouring system and pouring method for aluminum alloy casting

An aluminum alloy casting and anti-gravity pouring technology, which is applied in the field of metal casting, can solve the problems of unsatisfactory feeding capacity, slag discharge capacity, insufficient pouring, and looseness of the annular runner system, and achieves improved slag removal and exhaust. Ability, quality stability improvement, avoid the effect of insufficient water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

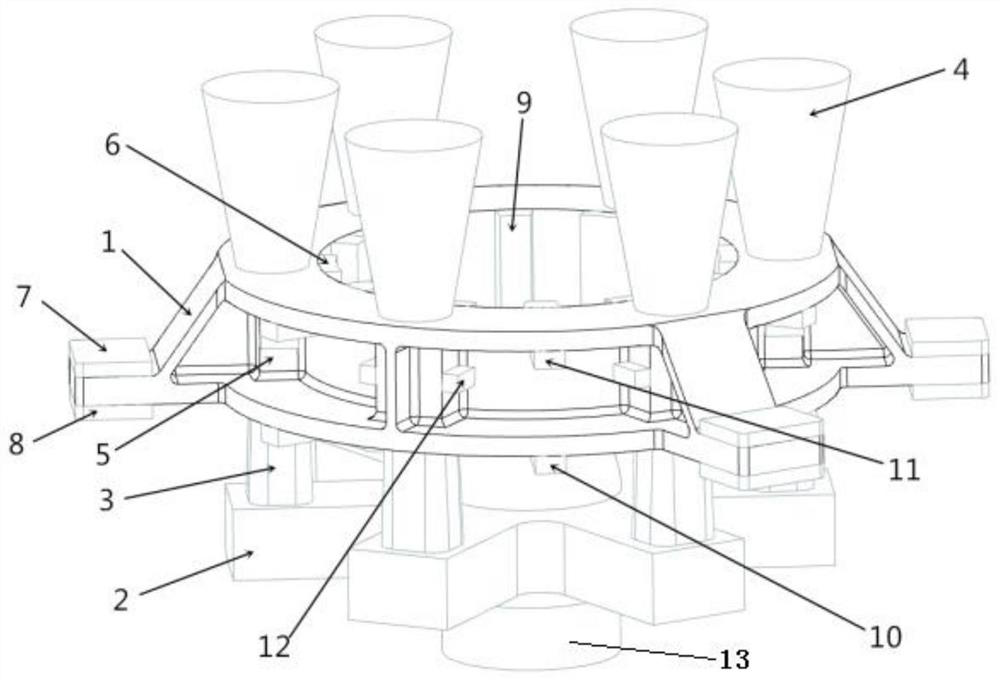

[0033] Such as figure 1 As shown, a double-supplement interrupted anti-gravity pouring system for aluminum alloy castings according to the present invention includes a cavity, a riser 13 and a chilled iron assembly. The cavity includes several body sprues 5, and the The upper side of the cavity is provided with a number of risers 4 directly above the body sprues 5 one by one, and the lower side of the cavity is provided with a number of base plate straights directly below the body sprues 5 one by one. The runner 3, the riser 13 is located below the cavity, and communicates with several bottom sprues 3 through the bottom runner 2 respectively, and the cold iron assembly divides the cavity into several regions. The location of the vertical reinforcing rib on the aluminum alloy casting 1 is its thick and large part, and the riser 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com