Pressure-varying air-exhausting duct structure

An air exhaust duct and pressure-transforming technology, which is applied to vertical pipes, building components, building structures, etc., can solve the problems of inconvenient installation of pressure-transforming components, positioning and installation troubles, and achieve low production costs and convenient installation. The effect of installation and easy placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

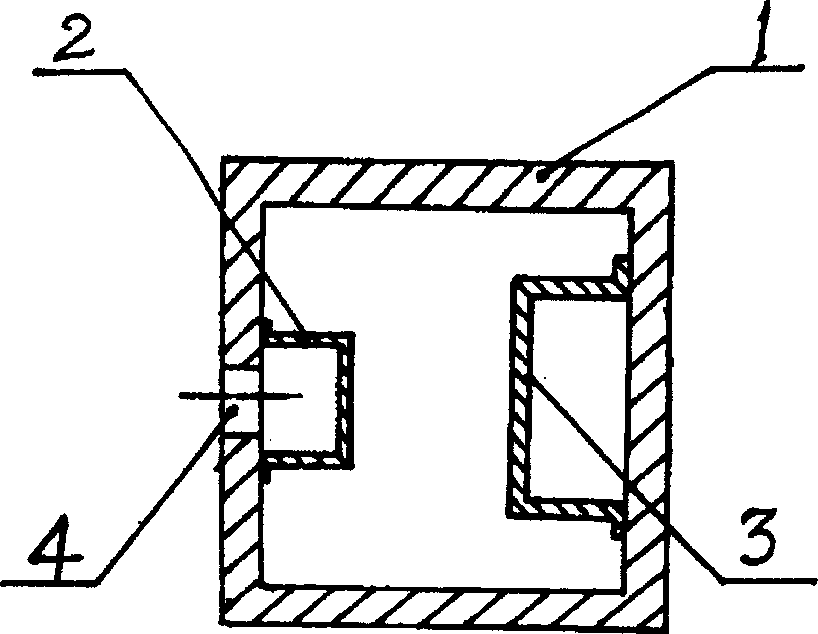

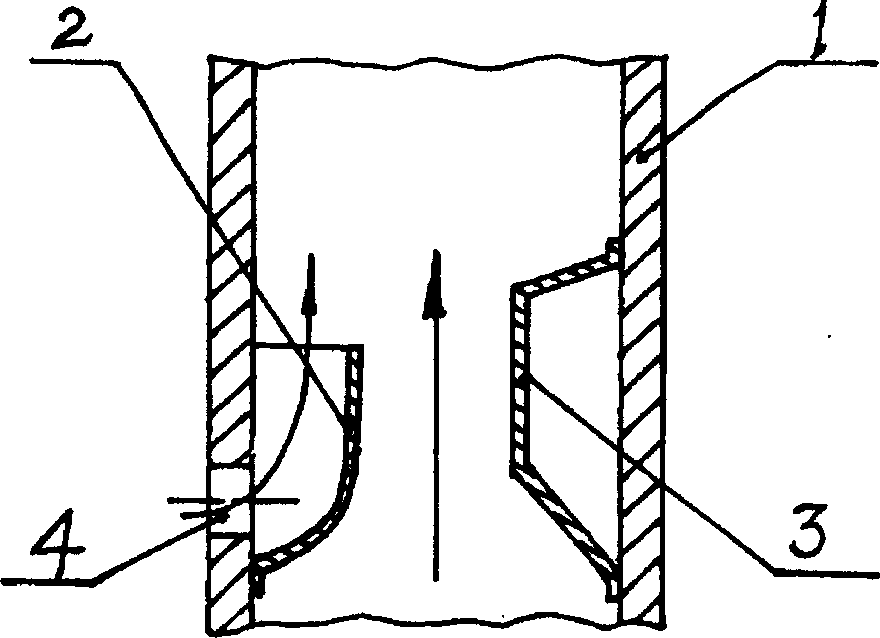

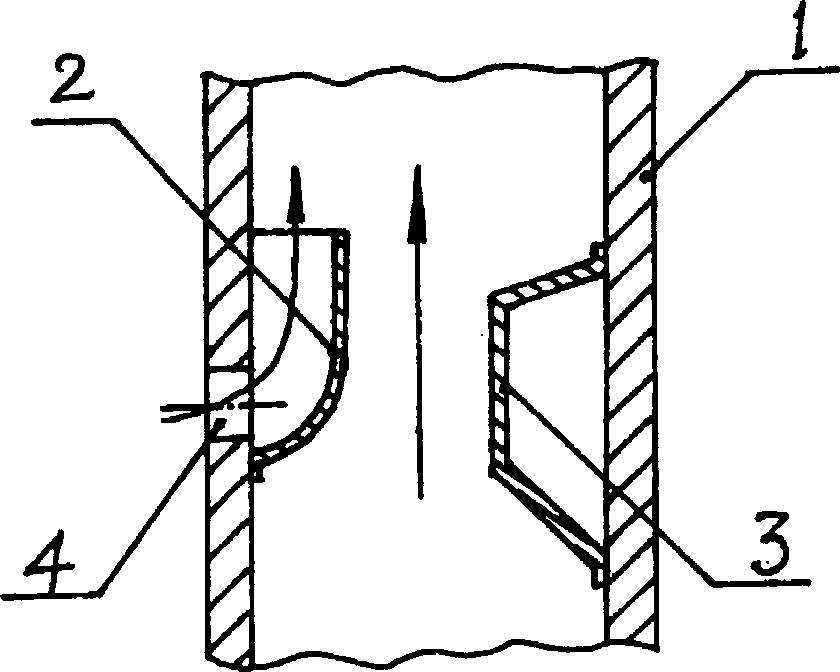

[0024] exist figure 1 The schematic diagram shown and figure 2 , image 3 , Figure 4 In the schematic diagram shown, the present invention is composed of a gas discharge pipe 1 provided with an air inlet 4, an exhaust guide pipe 2 and an airflow pressure transformation part 3, and the exhaust guide pipe 2 and the airflow pressure transformation part 3 are all arranged in the gas discharge pipe On the inner wall of 1, the exhaust guiding pipe 2 is arranged on the inner wall of the above-mentioned gas discharge pipeline 1 at the opposite side of the gas flow transformation part 3. There is an exhaust space reserved between the exhaust guide pipe 2 and the airflow pressure transformation part 3, and the guide channel of the exhaust guide pipe 2 is connected with the air inlet 4 on the gas discharge pipe 1, wherein the airflow pressure transformation part 3 is two At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com