Hole pile construction method

A construction method and technology of hole piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of a large number of mortar drilling efficiency, low, secondary drilling, etc., to reduce the cost of vibratory hammers and hoisting machinery The effect of magnitude, reducing resistance, and avoiding bumps and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

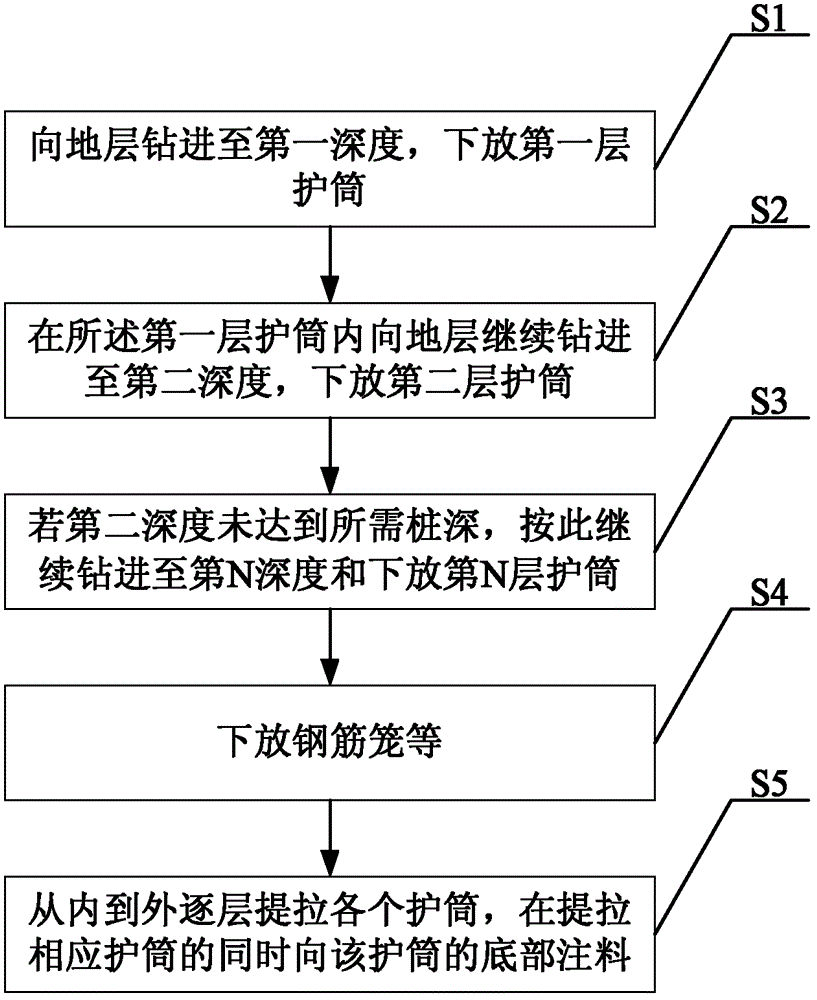

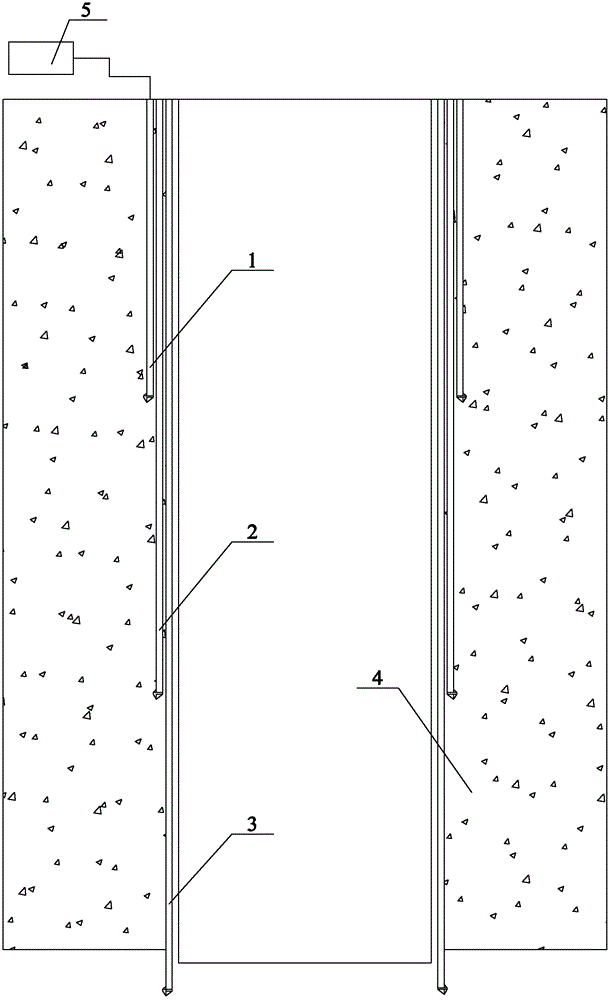

[0026] Please refer to figure 1 and combine figure 2 , the hole pile construction method of the embodiment of the present invention includes a hole-forming step and a pile-forming step, and the hole-forming step includes further comprising:

[0027] S1: Drill into formation 4 to the first depth, lower the first layer of casing 1;

[0028] S2: c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com